Construction Hoist SC150Z,Racks and Pinion Adopts Special Material and Heat-treatment Technique

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

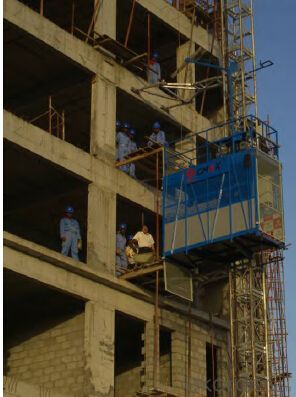

SC Hoist is a Rack and Pinion EL. Lift, used on construction site for transportation of personnel and materials. It is installed and dismounted conveniently and can grow as high as the buildings grow in height.

There are single cage and twin cage hoists. A single cage can be quickly transformed into twin cage hoist by adding a cage and other parts. The hoist payload can be increased by adding counterweight equipment.

SC Hoist has reliable electrical and mechanical safety device. It is a efficient and safety vertical transporting equipment.

Structure of Construction Hoist Description

Feature: Construction Hoist Condition: New Application: Construction

Payload(kg):2700 Lifting Speed(m/min):33 Motor Power(kw): 3*15

Safety Device: SAJ50-1.2 Cage: Single Counterweight: No

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: SC150Z

Construction Hoist Specifiction

Main technical data | Unit | Value |

Rated load | kg | 1500 |

Rated erection load | kg | 1000 |

Jib attachment rated load | kg | 300 |

Cage size | m | 3.0×1.3×2.5 |

Maximum lifting height | m | 450 |

Lifting speed | m/min | 0~63 |

Rated output | kW | 3×16.5 |

Voltage rating | V | 380/440 |

Rated frequency | Hz | 50/60 |

Rated current | A | 3×34.4 |

Power supply fuses | A | 125 |

Protective class | / | IP55 |

Load duration factor | / | FC-25% |

Safety device | m/s | 1.4 |

Enclosure weight | kg | 980 |

Cage weight | kg | 2000 |

Counterweight | kg | / |

Mast section weight | kg | 125/145 |

Mast section length | mm | 1508 |

Packaging & Delivery of Construction Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Building hoist inmmages

Main Parts of Construction Hoist

● The gearing adopts imported bearing, enameled cable, and oil seal.

● The electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG.

● The racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts.

● The steel structure uses quality steel from famous domestic manufactures.

● The surface of the structure can apply paint-spray, parkerozing baking finish or hot galvanizing processing according

to users requirements,

● The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminm board.

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: What is the function or use of constructing a building hoist?

- <p>The purpose of building hoists is to facilitate the vertical transportation of materials, equipment, and sometimes personnel during the construction process. They are essential for moving heavy items to various floors or levels of a building under construction. Hoists enhance efficiency, reduce manual labor, and improve safety by minimizing the risk of accidents associated with manual handling of heavy loads. They are particularly crucial in high-rise construction where access is limited and the volume of materials to be moved is substantial.</p>

- Q: Is it possible to utilize building hoists in environments with high altitudes?

- <p>Yes, building hoists can be used in high-altitude environments, but their performance may be affected. At high altitudes, reduced air density can lead to decreased efficiency in hoist operations, particularly those powered by combustion engines. It's crucial to select hoists designed for high-altitude use, which may include features such as high-altitude ignition systems and special lubricants. Additionally, regular maintenance and adjustments to the hoist's operation parameters are necessary to ensure safety and optimal performance.</p>

- Q: This question asks for the different types of lifting equipment that can be compatible with a building hoist.

- <p>Building hoists are commonly used in construction projects to lift materials and personnel. Compatible lifting equipment includes various types of hooks, slings, and shackles for securing loads; lifting beams for heavier or bulkier items; and specialized attachments like pallet forks for moving palletized loads. It's crucial to use lifting equipment that is rated for the weight of the load and compatible with the hoist's specifications to ensure safety and efficiency.</p>

- Q: Is it possible to substitute an automatic lifting device with a manual one in construction projects?

- <p>While it is technically possible to use a manual lifting device in place of an automatic one for certain construction tasks, it is not generally recommended. Manual lifting devices are typically less efficient, slower, and can pose safety risks due to the physical effort required. They may also not meet the load-bearing requirements of heavy construction materials. Automatic lifting devices are designed for efficiency, safety, and to handle heavy loads, making them more suitable for construction work. It's crucial to adhere to safety standards and use appropriate equipment for the task at hand.</p>

- Q: Is the construction elevator a special equipment

- Belong to special equipment construction lifter, but generally used as home building municipal engineering does not belong to the quality and technical supervision management, but belong to the administration of urban construction. Because the system of quality control unless invited, shall not be involved in military, aerospace, nuclear industry, mine, municipal, sea, railway locomotive hoisting machinery management.

- Q: Is it possible to repair or replace a hydraulic pump used in a building hoist system?

- <p>Yes, a hydraulic pump used in a building hoist can be repaired or replaced. If the pump is damaged or worn out, it can be serviced or repaired by professionals who specialize in hydraulic systems. If the damage is beyond repair, a new pump can be sourced and installed to ensure the hoist operates safely and efficiently. Regular maintenance and inspection are crucial to prevent major issues and to extend the life of the hydraulic pump.</p>

- Q: This question asks about the procedures and methods for maintaining and repairing a building hoist, which is a type of lifting equipment used in construction.

- <p>To maintain and repair a building hoist, follow these steps: Regularly inspect the hoist for any signs of wear and tear or malfunction. Lubricate moving parts as per the manufacturer's recommendations to reduce friction and prevent rust. Check and replace worn cables, pulleys, and other components. Ensure that safety devices like limit switches and emergency stops are functioning correctly. For repairs, address any mechanical failures, replace broken parts, and make sure the electrical system is in good condition. Always follow the manufacturer's guidelines and consult with a professional if the issue is complex or beyond your expertise. Regular maintenance and prompt repairs can extend the life of the hoist and ensure safe operation.</p>

- Q: Explain the key differences between electric and hydraulic lifting equipment, including their power sources, efficiency, and applications.

- <p>Electric lifting equipment is powered by electric motors and typically operates through cables or batteries, making them quieter and more environmentally friendly. They are often used in indoor settings where noise and emissions are a concern. Hydraulic lifting equipment, on the other hand, uses hydraulic fluid and pistons to generate force, providing high power and torque. They are commonly used in heavy-duty applications and outdoors. Electric systems are generally more energy-efficient and have lower maintenance costs, while hydraulic systems offer greater power density and can handle heavier loads.</p>

- Q: Is it permissible to use a building hoist for lifting people or animals?

- <p>No, building hoists are not designed for lifting people or animals. They are specifically engineered for the transportation of materials and construction equipment. Using a building hoist for this purpose is dangerous and can lead to accidents. It is essential to adhere to safety regulations and use appropriate equipment for lifting people or animals to ensure their safety and comply with legal standards.</p>

- Q: Is it possible to utilize a hydraulic cylinder in the construction of a building hoist?

- <p>Yes, hydraulic cylinders can be used in building hoists. They are often employed in lifting systems due to their ability to generate large forces in a controlled manner. Hydraulic cylinders provide smooth and precise control over heavy loads, which is crucial for the safe and efficient operation of a building hoist. They can handle the vertical movement of materials and personnel in construction settings, ensuring a stable and reliable lifting mechanism.</p>

Send your message to us

Construction Hoist SC150Z,Racks and Pinion Adopts Special Material and Heat-treatment Technique

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords