Building Hoist with CE Certificated SC200

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

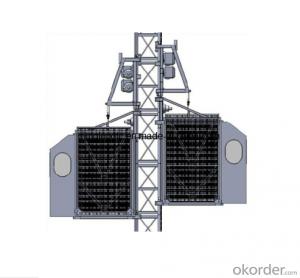

Construction Building Hoist with CE Certificated SC200

We are special supplier of building hoist in China, our building hoist have been Widely exported to all over the world and won good reputation, whose payload capacity is as much as 10000kg, lifting speed can reach up to 96m/min, and the erection height reaches up to 550m., our products have been widely used for transportation for both men and cargo in field of general buildings, but also industry, electric power, mining well, oil, chemical industry etc.

SC270TD, SC270/270TD building hoist:

1). Each cage load capacity: 2700kg

2). Lifting speed: 36m/min, or 0∼ 63m/min, or 0∼ 96m/min

3). Mast section: Paint or hot dipping zinc

4). Cage: Single cage or twin cage

5). Recommended cage inner dimension(LxWxH)(m): 2.5x1.3 x2.5; 3.0x1.3x2.5; 3.2x1.5x2.5; 3.6x1.5x2.5; 3.8x1.5x2.5; 4.0x1.5x2.5; 4.2x1.5x2.5, cage dimension is according to requirement of customer and special project.

6). Motor and reducing device: Made in China, can be SEW Germany according to requirements.

7). Counterweight: With counterweight or without counterweight

8). The colors of cage: Yellow, or red, or blue

9). Other each cage load capacity for your to choose: 1000kg, 2000kg, 2700kg, or 3200kg

| Type | Payload kg | Lifting speed m/min | Motor power kW | Inverter power kW | Counter Weight kg | ||

| Low speed | Single cage no counterweight | SC200GD | 2000 | 0~46 | 3×15 | 45 | 0 |

| SC270GD | 2700 | 0~46 | 3×18.5 | 55 | 0 | ||

| SC320GD | 3200 | 0~46 | 3×22 | 75 | 0 | ||

| Twin cage no counterweight | SC200/200GD | 2×2000 | 0~46 | 2×3×15 | 2×45 | 0 | |

| SC270/270GD | 2×2700 | 0~46 | 2×3×18.5 | 2×55 | 0 | ||

| SC320/320GD | 2×3200 | 0~46 | 2×3×22 | 2×75 | 0 | ||

| Middle speed | Single cage no counterweight | SC120GZ | 1200 | 0~63 | 3×15 | 45 | 0 |

| SC200GZ | 2000 | 0~63 | 3×18.5 | 55 | 0 | ||

| Single cage with counterweight | SCD200GZ | 2000 | 0~63 | 2×15 | 30 | 2000 | |

| SCD270GZ | 2700 | 0~63 | 2×18.5 | 37 | 2000 | ||

| SCD320GZ | 3200 | 0~63 | 3×15 | 45 | 2000 | ||

| Twin cage no counterweight | SC120/120GZ | 2×1200 | 0~63 | 2×3×15 | 2×45 | 0 | |

| SC200/200GZ | 2×2000 | 0~63 | 2×3×18.5 | 2×55 | 0 | ||

| Twin cage with counterweight | SCD200/200GZ | 2×2000 | 0~63 | 2×15 | 2×30 | 2×2000 | |

| SCD270/270GZ | 2×2700 | 0~63 | 2×18.5 | 2×37 | 2×2000 | ||

| SCD320/320GZ | 2×3200 | 0~63 | 2×3×15 | 2×45 | 2×2000 | ||

| High speed | Single cage no counterweight | SC100GS | 1000 | 0~96 | 3×22 | 75 | 0 |

| SC120GS | 1200 | 0~96 | 3×22 | 75 | 0 | ||

| SC200G | 2000 | 0~96 | 3×22 | 90 | 0 | ||

| SC200GS | 2000 | 0~96 | 3×22 | 90 | 0 | ||

| Single cage with counterweight | SCD200G | 2000 | 0~96 | 3×15 | 45 | 2000 | |

| SCD200GS | 2000 | 0~96 | 2×22 | 45 | 2000 | ||

| SCD270G | 2700 | 0~96 | 3×18.5 | 55 | 2000 | ||

| SCD320GS | 3200 | 0~96 | 3×22 | 75 | 2000 | ||

| Twin cage no counterweight | SC100/100GS | 2×1000 | 0~96 | 2×3×22 | 2×75 | 0 | |

| SC120/120GS/ | 2×1200 | 0~96 | 2×3×22 | 2×75 | 0 | ||

| SC200/200G | 2×2000 | 0~96 | 2×3×22 | 2×90 | 0 | ||

| SC200/200GS | 2×2000 | 0~96 | 2×3×22 | 2×90 | 0 | ||

| Twin cage with counterweight | SCD200/200G | 2×2000 | 0~96 | 2×3×15 | 2×45 | 2×2000 | |

| SCD200/200GS | 2×2000 | 0~96 | 2×2×22 | 2×45 | 2×2000 | ||

| SCD270/270G | 2×2700 | 0~96 | 2×3×18.5 | 2×55 | 2×2000 | ||

| SCD320/320G | 2×3200 | 0~96 | 2×3×22 | 2×75 | 2×2000 | ||

| SCD320/320GS | 2×3200 | 0~96 | 2×3×22 | 2×75 | 2×2000 | ||

- Q: This question asks whether building hoists can be utilized in limited areas like rooms or tunnels.

- <p>Yes, building hoists can be used in confined spaces such as rooms or tunnels, but it depends on the specific design and size of the hoist. Compact and portable hoists are available for use in tight spaces. However, safety considerations, space dimensions, and the weight capacity of the hoist must be taken into account. It's crucial to ensure that the hoist is suitable for the confined area and that all safety protocols are followed to prevent accidents.</p>

- Q: This question asks for a comparison between lifting equipment used in indoor settings versus those used outdoors, focusing on their differences.

- <p>Indoor lifting equipment is designed for controlled environments, often smaller and more precise, with features like electric chain hoists or jib cranes. They are typically quieter, require less maintenance, and are suitable for tasks like assembly, manufacturing, and warehouse operations. Outdoor lifting equipment, such as gantry cranes or mobile cranes, is built to withstand harsh weather conditions, has higher load capacities, and is often used for construction, shipping, and heavy industry. These are more robust, may require more maintenance, and are designed for larger, heavier loads over uneven terrain.</p>

- Q: Why is the construction elevator not up to the roof

- The free end of the construction of the lift height is only 7.5 meters high, general construction elevator drive now is the case, so the hoisting cage height and drive around 4.5 meters high, the other national standard construction elevator ceiling limit moves, drive above about 1.8 meters away from the top of the rails. So it's the free end of the construction elevator that can't satisfy the roof. As long as they can set up effective adhesion measures, they can also get on the roof.

- Q: The safety officer shall be responsible for the work of the construction elevator

- In a nutshell, the security officer is responsible for overseeing, checking, training, maintaining, and dismantling

- Q: This question asks for the method to determine the maximum weight a building hoist can lift.

- <p>The lifting capacity of a building hoist is calculated by considering several factors including the hoist's motor power, the strength of the hoist's construction materials, and the safety factor. The manufacturer usually provides the maximum lifting capacity based on these factors. To calculate it manually, you would need to know the motor's lifting force, the efficiency of the hoist's mechanical system, and apply a safety factor to ensure the hoist operates within safe limits. It's important to follow the manufacturer's guidelines and never exceed the specified lifting capacity to prevent accidents and ensure the hoist's longevity.</p>

- Q: Do the elevator need to be installed when the main project is in construction

- The top brass usually need to install the construction elevator.

- Q: The construction elevator should have those procedures

- Installation and demolition plan, content can guide safe construction, and have complete approval procedure. The installation and demolition of the team must hold the certificate of safety of the above provincial competent authorities. There should be substantial content for the safety of the installation, the demolition of the staff and the safety technology of the driver. Should have basic design, hidden acceptance and concrete strength speech. The inspection and acceptance of the installation completed and the inspection presentation of the competent part. The construction elevator has a record. The elevator is using a copy of the original copy. An employee's special course post certificate. Other relevant safety information. The construction elevator is a larger vertical transport equipment, and the safety and blood lessons of previous accidents are profound. Strict inspection, the key prevention of elevator accidents, is the key link of the safety management at the construction site, and the safety management staff at all levels should be awake and familiar.

- Q: This question asks whether a building hoist can be utilized for lifting various kinds of objects.

- <p>Yes, a building hoist can be used for lifting multiple types of objects. It is designed to handle a variety of materials, including construction materials, tools, and equipment. The hoist's capacity and design may vary, allowing it to accommodate different weights and sizes. However, it is crucial to ensure that the hoist's lifting capacity is not exceeded and that the objects are secured properly to prevent accidents. Always refer to the manufacturer's guidelines for specific weight limits and safety procedures.</p>

- Q: What are the primary materials that are commonly utilized in the construction of hoists?

- <p>Hoists are typically constructed using a combination of metals and synthetic materials for strength and durability. Steel, particularly alloy steel, is a common choice due to its high tensile strength and resistance to wear. Aluminum is also used for its lightweight properties, especially in mobile hoists. Synthetic materials such as nylon or polyester are used for hoist ropes and cables due to their resistance to abrasion and corrosion. Additionally, hoists may incorporate components made from brass, bronze, or other metals for specific parts that require low friction or high resistance to corrosion.</p>

- Q: What are the steps and considerations for maintaining a building hoist to ensure its safety and functionality?

- <p>To maintain a building hoist properly, follow these steps: Regularly inspect the hoist for any visible damage or wear. Lubricate moving parts as per manufacturer's recommendations. Ensure all safety devices are functioning correctly, including limit switches and emergency stop buttons. Check the hoist's electrical system for any signs of damage or wear. Keep the hoist clean and free from debris. Conduct a thorough inspection after any incident or near miss. Regularly test the hoist's load capacity to ensure it is within safe limits. Train operators on safe hoist operation and maintenance procedures. Always follow the manufacturer's guidelines and local regulations for maintenance and inspection.</p>

Send your message to us

Building Hoist with CE Certificated SC200

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords