Building Hoist Single SCD200 Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist Single SCD200

CounterweightThe P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device, and the composition and function of each major part can be described as below:

1. Metal Structure

The metal frame is composed of: cage, mast, base frame & enclosure, anchorage and etc. The surface of these metal structures can be spray-painted and hot galvanized according to customers’ requirements.

Cage is of the main running & transporting part, whose dimension and shape can be customized according to the factual site condition. Entrance & exit doors can be produced as up & down sliding or ramping model for safety and convenience. Every set of P/M hoist can be equipped with single or double cages. The entrance & exit doors and the wall of the cage can be produced with steel net, perforated steel board or aluminum plastic board. The floor and ceiling parts can be produced with steel board. On the top of the cage, there is a trap door with 0.25 m2, equipped with the limit switches. When testing and repairing, workers can climb up to the top of the cage through the ladder inside the cage. When emergency happens, the trap door can be used as exit. There are hand rails installed on the top of the cage, protecting workers from falling.

In addition, the hoist can be equipped with driving cab and rebar carrier device according to the customers’ requirements.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

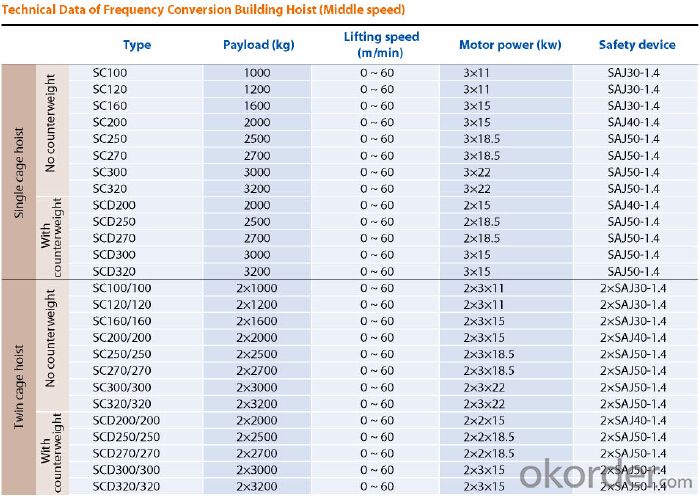

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Explain the distinctions between electric and hydraulic building hoists, focusing on their mechanisms, efficiency, and applications.

- <p>Electric building hoists use electric motors to drive the hoisting mechanism, which can be more efficient and require less maintenance than hydraulic systems. They are often quieter, have fewer leaks, and can be more precise in their operation. Hydraulic building hoists, on the other hand, use hydraulic pressure to lift loads. They can handle heavier loads and are often used in situations where there is no electricity available. However, they may require more maintenance due to potential leaks and can be less precise in their movements.</p>

- Q: What measures should be taken to ensure safety when operating electric-motor powered building hoists?

- <p>When using electric-motor type building hoists, safety precautions include: ensuring all safety devices are in good working order, regularly inspecting and maintaining the hoist, following the manufacturer's guidelines, never overloading the hoist, keeping the hoist and its surroundings clean and free from obstructions, using proper lifting techniques, ensuring the hoist is stable and secure, wearing appropriate personal protective equipment, and training operators on the safe use of the hoist. Adhering to these precautions can significantly reduce the risk of accidents and ensure the safety of workers and the integrity of the construction process.</p>

- Q: This question asks whether a building hoist can be utilized for lifting various kinds of objects.

- <p>Yes, a building hoist can be used for lifting multiple types of objects. It is designed to handle a variety of materials, including construction materials, tools, and equipment. The hoist's capacity and design may vary, allowing it to accommodate different weights and sizes. However, it is crucial to ensure that the hoist's lifting capacity is not exceeded and that the objects are secured properly to prevent accidents. Always refer to the manufacturer's guidelines for specific weight limits and safety procedures.</p>

- Q: The maximum allowable deviation of the vertical is the vertical degree when the construction elevator is installed

- The development of the elevator is in a peak state, because most of the manufacturers or individuals to improve the utilization efficiency of space, more options for multistory buildings, which also need a device to convenient up and down by the goods. Due to the common elevator cost is high, bearing capacity is low, not suitable for carrying dozens of tons or hundreds of tons of cargo, so developed a high bearing capacity of hydraulic lift to assist in the production and transportation of goods. The elevators are both safe and super loadable, and convenient for maintenance, making the special industry grow faster.

- Q: Is it possible to utilize a double-rope lifting mechanism within the context of a building hoist?

- <p>Yes, a double-rope lifting system can be used in a building hoist. This system offers advantages such as increased safety due to redundancy and the ability to lift heavier loads compared to a single-rope system. The double-rope setup allows for the hoist to handle the load with two separate ropes, reducing the risk of failure and providing a more stable lifting platform. It's common in applications where high load capacities and safety are paramount, such as in construction for lifting materials and equipment.</p>

- Q: This question asks for the detailed specifications and dimensions of a building hoist, which is a type of construction equipment used to lift materials.

- <p>The specifications and measurements of a building hoist can vary significantly depending on the model and manufacturer. Generally, a building hoist (also known as a construction hoist or material hoist) is characterized by its load capacity, which can range from 500 kg to several tons. The height of the hoist is determined by the number of floors it serves, typically measured in meters. The width and depth are usually around 1.5 to 2 meters, and the speed can vary from 24 to 60 meters per minute. The power requirement is often between 3 to 7.5 kW. Safety features like overload protection, emergency stop, and limit switches are also standard. For precise specifications, it's essential to consult the manufacturer's data sheet for the specific model in question.</p>

- Q: Is it possible for a building hoist to experience malfunctions that lead to damage?

- <p>Yes, a building hoist can malfunction and cause damage. Malfunctions can occur due to various reasons such as mechanical failure, operator error, or poor maintenance. These malfunctions can lead to accidents, including dropped loads, structural damage, or even injuries to workers. Regular inspections, proper maintenance, and adherence to safety protocols are crucial to minimize the risk of hoist malfunctions in construction settings.</p>

- Q: This question is asking for a comparison between electric and hydraulic building hoists, focusing on their differences.

- <p>Electric and hydraulic building hoists differ primarily in their power source and operational mechanisms. Electric hoists use electric motors to lift and lower loads, which makes them more energy-efficient and quieter in operation. They also tend to have fewer maintenance requirements and are often easier to control with precise movements. Hydraulic hoists, on the other hand, use hydraulic pressure to move loads and are known for their ability to lift heavy loads with less effort. They are often preferred for applications requiring high lifting capacities and can be more compact. However, hydraulic hoists may require more maintenance due to the presence of seals and fluid systems, and they can be noisier than electric hoists.</p>

- Q: The elevator is banned from using elevators for more than a class of high winds

- More than 6 levels of wind are forbidden to be removed and used. More than 4 levels of wind are not allowed to rise, and more than 6 winds are prohibited.

- Q: Is it safe to use a lifting device with someone who has no experience with it?

- <p>It is generally not advisable to use a lifting device with someone who is not familiar with it. Lifting devices require proper training and understanding of their operation to ensure safety. Using such equipment without proper knowledge can lead to accidents and injuries. It is crucial to ensure that anyone operating a lifting device has received the necessary training and is familiar with the specific device's safety protocols and operation procedures.</p>

Send your message to us

Building Hoist Single SCD200 Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords