Construction Hoist SCD200 with Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of SCD200 Construction Hoist Description

To serve the increasing demand for highrise construction, we developed the high speed VF hoist, with a max.lifting speed of 96 m/min.

It has the following structure:

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/F control: the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoids slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the energy consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack,pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection, low voltage protection, overcurrent, overload and anti-stalling protection functions.

7. The System applies the special software for hoists developed by our company, making the operation more safe and reliable.

Main Features of SCD200 Construction Hoist

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing.

4. Both domestic and imported driving systems are available.

SCD200 Construction Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Single Cage Hoist | No Counterweight | SC100 | 1000 | 0~60 | 3*11 | SAJ30-1.4 |

| SC120 | 1200 | 0~60 | 3*11 | SAJ30-1.4 | ||

| SC160 | 1600 | 0~60 | 3*15 | SAJ30-1.4 | ||

| SC200 | 2000 | 0~60 | 3*15 | SAJ40-1.4 | ||

| SC250 | 2500 | 0~60 | 3*18.5 | SAJ50-1.4 | ||

| SC270 | 2700 | 0~60 | 3*18.5 | SAJ50-1.4 | ||

| SC300 | 3000 | 0~60 | 3*22 | SAJ50-1.4 | ||

| SC320 | 3200 | 0~60 | 3*22 | SAJ50-1.4 | ||

| With Counterweight | SCD200 | 2000 | 0~60 | 2*15 | SAJ40-1.4 | |

| SCD250 | 2500 | 0~60 | 2*18.5 | SAJ50-1.4 | ||

| SCD270 | 2700 | 0~60 | 2*18.5 | SAJ50-1.4 | ||

| SCD300 | 3000 | 0~60 | 3*15 | SAJ50-1.4 | ||

| SCD320 | 3200 | 0~60 | 3*15 | SAJ50-1.2 |

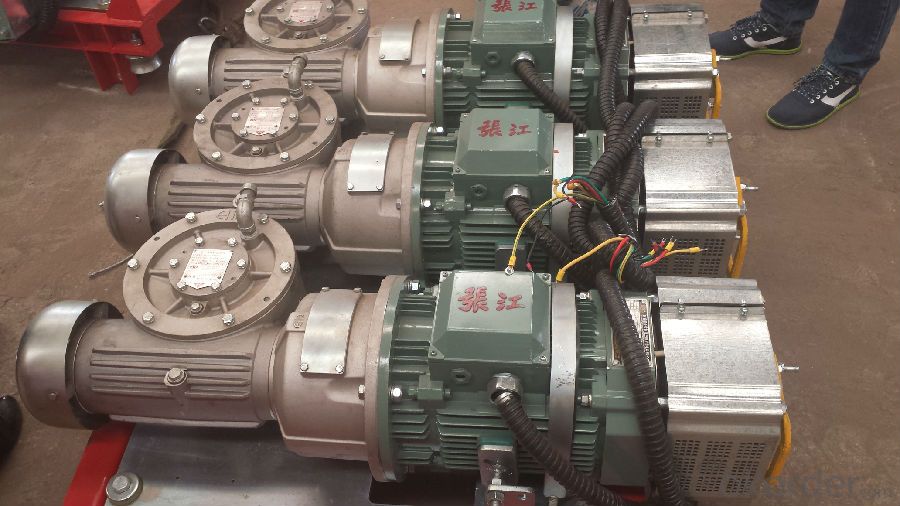

Images of SCD200 Construction Hoist

FAQ of SCD200 Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to use a building hoist for material transportation in both indoor and outdoor environments, especially in confined spaces within industrial zones?

- <p>Yes, building hoists can be used both indoors and outdoors in industrial areas, even with limited space. They are designed for material transportation during construction and are adaptable to various environments. For indoor use, hoists are often enclosed to protect from weather and debris. Outdoors, they may require additional weatherproofing. In confined spaces, compact and tower hoists are used to save space. However, safety regulations and space constraints must be considered to ensure proper installation and operation.</p>

- Q: This question asks for the different types of lifting equipment that can be compatible with a building hoist.

- <p>Building hoists are commonly used in construction projects to lift materials and personnel. Compatible lifting equipment includes various types of hooks, slings, and shackles for securing loads; lifting beams for heavier or bulkier items; and specialized attachments like pallet forks for moving palletized loads. It's crucial to use lifting equipment that is rated for the weight of the load and compatible with the hoist's specifications to ensure safety and efficiency.</p>

- Q: This question asks for the method to determine the maximum weight a building hoist can lift.

- <p>The lifting capacity of a building hoist is calculated by considering several factors including the hoist's motor power, the strength of the hoist's construction materials, and the safety factor. The manufacturer usually provides the maximum lifting capacity based on these factors. To calculate it manually, you would need to know the motor's lifting force, the efficiency of the hoist's mechanical system, and apply a safety factor to ensure the hoist operates within safe limits. It's important to follow the manufacturer's guidelines and never exceed the specified lifting capacity to prevent accidents and ensure the hoist's longevity.</p>

- Q: This question asks for an explanation of the different types of building hoists used in construction.

- <p>Building hoists, also known as construction hoists or material hoists, are essential for moving materials and personnel in high-rise construction projects. The main types include: 1. <strong>Freestanding Hoists</strong>: These do not require a building structure for support and are self-supporting. 2. <strong>Cladding Hoists</strong>: Attached to the building's facade, used for moving materials during cladding work. 3. <strong>Personnel Hoists</strong>: Specifically designed for transporting workers, ensuring safety with features like cages and safety devices. 4. <strong>Material Hoists</strong>: Built to transport heavy construction materials and are robust and durable. 5. <strong>Electric Hoists</strong>: Operated by electricity, offering precise control and energy efficiency. 6. <strong>Hydraulic Hoists</strong>: Utilize hydraulic systems for lifting, known for their smooth operation and heavy load capacity. Each type serves a specific purpose and is chosen based on the project's requirements and the stage of construction.</p>

- Q: This question asks for the process of changing the height at which a building hoist operates.

- <p>Adjusting the height of a building hoist typically involves a few key steps. First, ensure the hoist is powered off and disconnected from any power source to ensure safety. Next, locate the hoist's height adjustment mechanism, which may be a set of bolts or a telescoping column. Loosen any locking nuts or bolts that secure the current height setting. Adjust the hoist to the desired height by raising or lowering the platform or mast. Once the desired height is reached, tighten the locking nuts or bolts to secure the hoist in place. It's crucial to check the manufacturer's guidelines for your specific hoist model, as the process may vary. Always follow safety protocols and consult with a professional if you're unsure about any steps.</p>

- Q: This question asks about the method to determine the maximum weight a building hoist can safely support.

- <p>Calculating the maximum load capacity of a building hoist involves several factors. First, consider the hoist's mechanical design and the manufacturer's specifications, which provide the rated load capacity. This is the maximum weight the hoist is designed to handle. Next, assess the condition of the hoist, as wear and tear can reduce its capacity. Additionally, consider the strength of the supporting structure and the safety factor, which is typically a multiplier of the rated load capacity to ensure safety. For example, if the hoist is rated for 1000 kg, a safety factor of 1.5 means the actual maximum load should not exceed 667 kg (1000 kg / 1.5). Always consult with engineers and follow local regulations and standards for precise calculations.</p>

- Q: This question asks for measures to avoid accidents that may occur due to the misuse of a building hoist.

- <p>To prevent accidents caused by improper use of a building hoist, it's crucial to follow safety protocols strictly. Ensure all hoist operators are trained and certified. Regularly inspect and maintain the hoist equipment to check for any defects or wear. Never overload the hoist, and always secure the load properly. Implement clear communication procedures among workers, especially when the hoist is in operation. Set up barriers or warning signs to keep unauthorized personnel away from the hoist area. Finally, conduct regular safety drills to prepare for emergencies and reinforce safety practices among the workforce.</p>

- Q: Should a fire extinguisher be equipped in the construction elevator?

- The temporary building area shall be equipped with fire equipment according to the regulations. In general temporary facilities, each 100m2 is equipped with two 10L extinguisher. If the total area of a large temporary facility exceeds 1200m2, there shall be a special service for fire fighting, such as taiping pail, water bucket (pool), and huangsha ponds, etc. No items shall be piled up around the facilities. Between temporary carpenter's room, paint room, wood and machine tools, each 25m2 should be equipped with a suitable extinguisher. The oil depot and dangerous goods warehouse shall be equipped with sufficient quantity and type suitable extinguisher.

- Q: Is it possible to utilize a building hoist for the purpose of raising construction materials or machinery?

- <p>Yes, a building hoist is specifically designed for lifting materials and equipment in construction settings. It is a temporary vertical transportation system used to move materials, tools, and sometimes personnel between different floors of a building under construction. Building hoists are essential for efficient construction processes, ensuring that materials are delivered to the correct levels without the need for manual labor, which can be time-consuming and hazardous.</p>

- Q: Is it possible to replace an electric motor with a hydraulic cylinder in an electric-hydraulic lifting system?

- <p>No, a hydraulic cylinder cannot be used in place of a motor in an electric-hydraulic lifting system. A hydraulic cylinder is a component that converts hydraulic pressure into linear motion, while an electric motor converts electrical energy into mechanical energy. In an electric-hydraulic system, the motor drives a hydraulic pump, which generates the pressure needed to actuate the cylinder. The motor is essential for providing the power source, and the cylinder is the actuator that uses this power to perform work. Replacing the motor with a cylinder would result in a system without a power source, rendering it inoperative.</p>

Send your message to us

Construction Hoist SCD200 with Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords