Building Hoist SCD200 with Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

The general building hoist manufactured by our company have the features as good quality, long life, wide application range and convenient for maintenance. The gearing adopted bearing,enameled cable, and oil seal. The electric parts adopt products from worl renowned manufacturers such as Schneider, Siemes, and LG. The racks and pinion adopts specal material and heat-treatment technique, which prolong the life of these parts. The steel structure uses quality steel from famous domestic manufacturers. The surface of the structure can apply paint-spray, parkerizing baking finish or hot galvanizing processing according to users requirments. The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminum board.

Main Features of Building Hoist

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing..

Building Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Single Cage Hoist | No Counterweight | SC100 | 1000 | 33 | 2*11 | SAJ30-1.2 |

| SC120 | 1200 | 33 | 2*11 | SAJ30-1.2 | ||

| SC160 | 1600 | 33 | 2*11 | SAJ30-1.2 | ||

| SC200 | 2000 | 33 | 3*11 | SAJ40-1.2 | ||

| SC250 | 2500 | 33 | 3*11 | SAJ50-1.2 | ||

| SC270 | 2700 | 33 | 3*15 | SAJ50-1.2 | ||

| SC300 | 3000 | 33 | 3*15 | SAJ50-1.2 | ||

| SC320 | 3200 | 33 | 3*15 | SAJ50-1.2 | ||

| With Counterweight | SCD200 | 2000 | 33 | 2*11 | SAJ40-1.2 | |

| SCD250 | 2500 | 33 | 2*11 | SAJ50-1.2 | ||

| SCD270 | 2700 | 33 | 2*15 | SAJ50-1.2 | ||

| SCD300 | 3000 | 33 | 2*15 | SAJ50-1.2 | ||

| SCD320 | 3200 | 33 | 2*15 | SAJ50-1.2 |

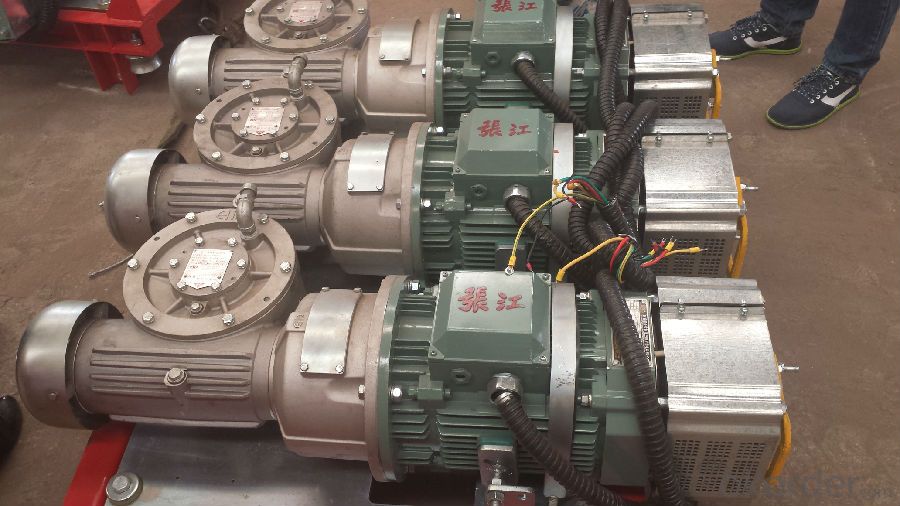

Images of Building Hoist

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Can a construction elevator use a single cage

- Can use single hanging cage, an accident is a management issue could not be struck down so many people, if such construction lifter dual-use goods elevator belongs to the people, 19 people find this elder brothers say batter to death then top with manned elevator nor safe, in fact is a regular inspection, site do not have an accident can only say that the site is too lax

- Q: How long does the construction elevator do a crash test

- Construction lifter before put into use, must pass a drop test, using every three months should do a drop test, to adjust for safety device, braking distance will be falling not more than 1.2 m, after test and normal operation of every happening for action, must be to reset the attached safety device. The adjustment, repair, or identification of the anti-falling safety device shall be carried out by the manufacturer or designated authorized unit, which shall be operated by the professional at the time of the crash test. General can at the local special equipment inspection institutions detection, can also be tested in other qualified enterprises, such as: wuhan science, Shanghai special survey, qufu golden horse machinery testing!

- Q: How does the elevator operate

- The application of the construction elevator has gained popularity over the years, and has attracted many employees. The construction elevator is a highly skilled industry, so it is required that the professionals must master certain expertise. Here is a knowledge of how to operate a lift machine, hoping to help you.

- Q: The construction of more than many floors must be used for construction elevators

- The average height is more than 12 stories. Construction elevators are often called construction elevators, but construction lifts include a broader definition, and construction platforms are part of the construction elevator series. Simple construction elevator is by car, driving mechanism, standard section, attached to the wall, chassis, fence, electrical system and so on several parts, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction elevator is usually used with tower crane on the construction site, the average load in 1-3 tons, running speed is 1 to 60 m/min. The construction elevator of our country is more and more mature, and gradually goes to the international.

- Q: What specific regulations or conditions must be met when utilizing lifting equipment in construction or factory environments?

- <p>Yes, there are special requirements for using lifting equipment in construction sites and factories. These include adherence to safety regulations, regular maintenance and inspection, proper operator training, and ensuring the equipment is suitable for the task. Compliance with local and national laws such as OSHA in the U.S. or CE marking in the EU is crucial. Equipment must be certified safe for use, and operators must be licensed and follow safety protocols. Additionally, load capacities must be respected, and lifting operations must be planned and supervised to prevent accidents.</p>

- Q: This question asks for safety precautions that should be taken when using a building hoist, which is a type of lifting equipment used in construction.

- <p>Safety measures for using a building hoist include regular inspections and maintenance, ensuring all safety devices are in good working order, securing all loads properly, and not overloading the hoist. Operators must be trained and certified. Protective barriers should be in place to prevent unauthorized access. Emergency stop switches should be readily accessible. Workers should wear appropriate personal protective equipment, and communication between the hoist operator and those on the ground should be clear and effective. Adhering to these measures helps prevent accidents and ensures the safe operation of the building hoist.</p>

- Q: Is it possible to use a lifting device to lift objects that are heavier than its specified maximum load?

- <p>No, a lifting device should never be used to lift objects that exceed its rated load capacity. Doing so can lead to catastrophic failure of the device, potentially causing serious injury or death. Always adhere to the manufacturer's specifications to ensure safety and prevent accidents. Overloading a lifting device can result in structural damage, compromised safety mechanisms, and increased risk of collapse or dropping the load. It is crucial to respect the load limits to maintain the integrity and reliability of the lifting equipment.</p>

- Q: This question asks about the various mechanisms that enable lifting in building hoists, which are essential for construction projects.

- <p>Building hoists utilize several types of lifting mechanisms to efficiently move materials and personnel. The most common types include: 1. Geared Hoists, which use a system of gears to lift and lower loads. 2. Electric Chain Hoists, powered by electric motors and are suitable for heavier loads. 3. Air Hoists, which use compressed air to generate lifting force and are ideal for environments where electricity is a hazard. 4. Manual Chain Hoists, operated by hand and best for lighter loads. 5. Electric Wire Rope Hoists, which offer high lifting capacities and are controlled by electric motors. 6. Pneumatic Hoists, similar to air hoists but use pneumatic power for lifting. Each type has specific applications and safety considerations, making them suitable for different construction needs.</p>

- Q: This question asks if building hoists can be utilized for extended periods of time in construction projects.

- <p>Building hoists are generally designed for temporary use in construction projects, facilitating the movement of materials and personnel. They are not intended for long-term operations. Their design and safety features cater to the specific needs of construction phases, which are temporary by nature. For permanent installations or long-term material handling, other types of elevators or lifts are more suitable. It is crucial to adhere to the manufacturer's guidelines and local regulations regarding the use and duration of operation for building hoists to ensure safety and compliance.</p>

- Q: What types of materials can be transported using a building hoist?

- <p>A building hoist can lift a variety of materials, including construction supplies such as bricks, cement, sand, and gravel. It can also transport larger items like steel beams, prefabricated concrete elements, and heavy machinery. Additionally, it is used to move tools, equipment, and sometimes personnel within the construction site. The specific materials that can be lifted depend on the hoist's capacity and the safety regulations in place. It's crucial to ensure that the load does not exceed the hoist's weight limit to maintain safety standards.</p>

Send your message to us

Building Hoist SCD200 with Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords