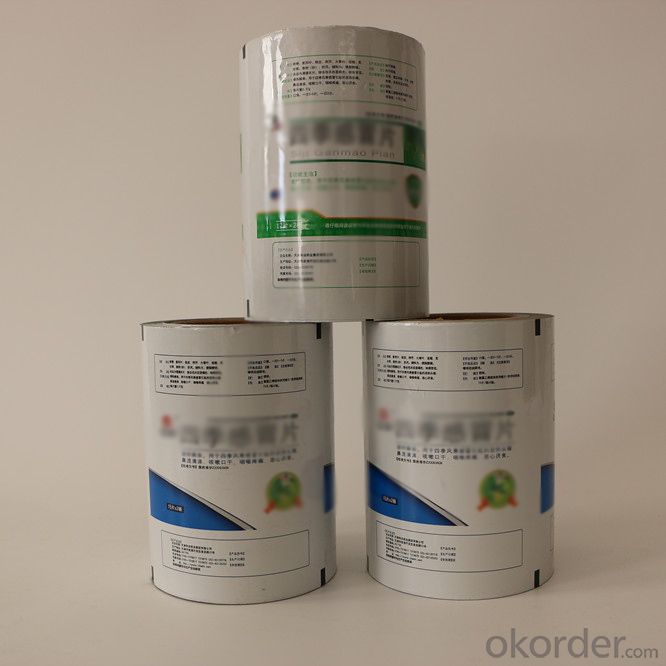

BOPP/VMCPP Laminated Film From China Quality Supplier Madicine Package Plastic Package

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BOPP/VMCPP Laminated Film From China Quality Supplier Madicine Package Plastic Package

Specification:

item | value |

Material | PET |

Type | Metallized Film |

Usage | Food&Medicine Film |

Feature | Moisture Proof |

Hardness | Soft |

Processing Type | Multiple Extrusion |

Transparency | Opaque |

Place of Origin | China |

Packing & Delivery

Oxygen Barrier 2-Layer Laminated metallized packaging PET PE flim

A.Foam film and Craft paper with the film roll body

B.Craft paper with the roll ends

C.Customized label without manufactory information or factory label available

D.Customized packing or packing according to the diameter by factory E.Wooden pallet

FAQ:

1. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2.what can you buy from us?

metallized film,metalized laminating film,VMPET,VMCPP,plastic film

3. why should you buy from us not from other suppliers?

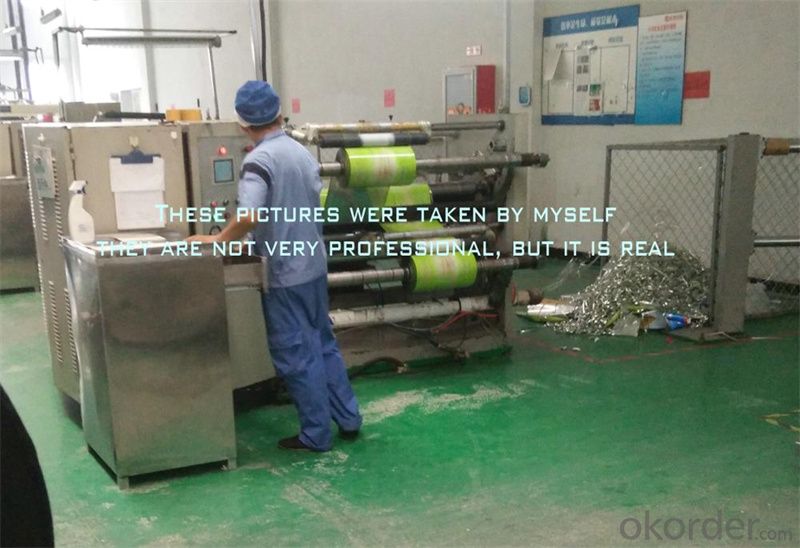

Baode has ten standardized production workshop, dozens of advanced production equipment, professional management idea, advanced testing equipment and excellent pre-market after-sales service.

4. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese

Device Show

- Q: How are membranes classified?

- HDPE film. HDPE film is a kind of tough semi transparent film. Its appearance is milky and its surface glossiness is poor. The tensile strength, moisture resistance, heat resistance, oil resistance and chemical stability of HDPE films are better than those of LDPE films, and they can also be sealed by heat. But the transparency is less than that of LDPE. HDPE can be made into thin film with thickness of 0.01. L. Its appearance is similar to that of thin silk paper. It feels comfortable and is called "paper film". It has good strength, toughness and opening, and can be added with a small amount of light calcium carbonate to enhance the paper feel and reduce the cost. HDPE paper film is mainly used for making all kinds of shopping bags, garbage bags, fruit packing bags and all kinds of food packaging bags and so on. Because of its poor air tightness and no incense retention, the storage period of packaged food is not long. In addition, the HDPE film can be used as a heat sealing layer of the cooking bag because of its good heat resistance.

- Q: Why should farmers cover plastic film when sowing in the spring?

- 1. warming up and promoting the decomposition and release of soil nutrients2. moisturizing, improve the survival rateSoil moisture, except irrigation, mainly comes from rainfall. After covering the membrane, on the one hand, because of the barrier of plastic film, the evaporation of soil water is reduced and the dissipation is slow; and the water drops formed in the membrane and then fall into the soil table, thereby reducing the loss of soil moisture and protecting soil moisture. On the other hand, the film can also be in the excessive rainfall, prevent the rain poured into the ridge, can play the role of waterlogging.3. promote growth and developmentThe application of plastic film mulching increased soil temperature and humidity, which was beneficial to early growth and rapid growth, and promoted the growth and development of plants. The growth period of plastic mulch is shortened to about one week.

- Q: What are the factors affecting the permeability of plastic film?

- Water column height. In the water permeability test, the water quantity in the water cup is changed, indicating that the water column height has no influence on the test result, so the water quantity is not strictly controlled, and the amount of the water can be poured into the water permeable cup with proper amount of water.

- Q: Can the concrete surface be covered with plastic film in winter construction?

- The advantage of covering plastic films is that water conservation concrete. The need for this chemical reaction. The plastic film prevents water from evaporating while causing heat dissipation and achieves the effect of heat preservation.

- Q: How can the weathering of the plastic film on the surface of FRP be removed?

- Corona treatment. It is commonly known as electrical discharge treatment, which is the most common treatment for plastic film production, printing and compounding. The process of EDM processing is that processor release high frequency and high power, produce small dense purple spark to the impact surface of plastic film, chemical bond breaking molecules on the surface of plastic film and degradation, increased the surface roughness. In addition, a large amount of ozone is generated at the same time of discharging, and the surface of the film is oxidized to produce a strong polar group, such as carbonyl group and peroxide, so that the surface of the plastic film is roughened, and the surface tension of the film is enhanced.

- Q: How to quickly remove the plastic film on the floor tiles?

- Various glue can be used to remove the blade + Banana water, pure water is colorless and transparent banana volatile liquid, have a strong smell of bananas, slightly soluble in water, soluble in various organic solvents, flammable, mainly used as paint solvents and thinners.

- Q: Are planted steel structure plastic film shed structures?

- A large parking garage (with roof) at the terminus of the subway: BuildingTwo, large urban overpass: BuildingThree radio and television towers: StructuresFour. Cross Harbour Tunnel: BuildingFive runway and taxiway: StructuresSix, the Three Gorges Dam: Structures

- Q: Wrap your legs in plastic film. How soon will they be removed?

- PVC film is mainly used in1. Sewage pipes2, PVC plastic film rod plate.3, construction, packaging, printing, equipment, process products.

- Q: How can concrete pavement be cured after being pressed? In general, concrete curing is made of thin films and concrete pavements

- After pouring concrete should be as early as possible insulation, moisture conservation, concrete after the light should be immediately maintained, in the surface of concrete cover plasticMaterial film,Strengthen the heat preservation and moisture conservation after the concrete is poured,Where conditions permit, you can increase moisture on cloth, water, strengthen moisture, heat preservationSupport. Heat preservation and moisture conservation is a good way to prevent drying and cracking of concrete pavement. The curing time should not be less than 7 days.

- Q: FFS plastic film bags are injection type?

- Tube film (blown film process) has become the best production method of FFS bag film products. FFS bag blown film technology is divided into single layer extrusion and multi layer extrusion technology according to its product form. Their production principle is basically the same, mainly equipment is different.

Send your message to us

BOPP/VMCPP Laminated Film From China Quality Supplier Madicine Package Plastic Package

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords