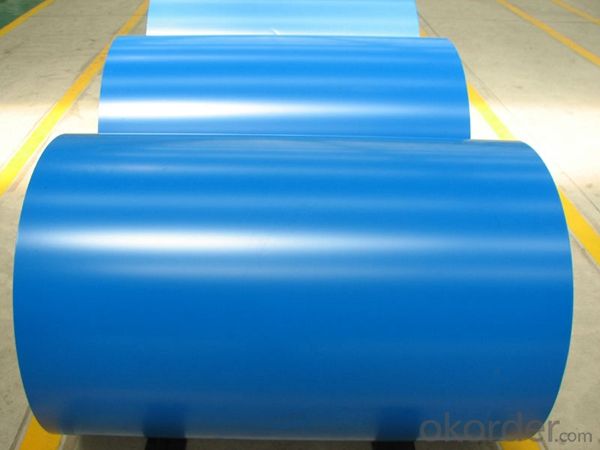

Color Coated Aluminum Pipes with Blue Aluminium Coils for ACP Top Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Blue Aluminium Coils for Color Coating ACP Top Coils

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Blue Aluminium Coils for Color Coating ACP Top Coils

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Blue Aluminium Coils for Color Coating ACP Top Coils

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Blue Aluminium Coils for Color Coating ACP Top Coils

6. Package and shipping of Blue Aluminium Coils for Color Coating ACP Top Coils

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum pipes be used for irrigation valves?

- Yes, aluminum pipes can be used for irrigation valves. Aluminum is a durable and lightweight material that is resistant to corrosion, making it suitable for irrigation systems.

- Q: One aluminum products, T6 hardness is not up to the requirements of heat treatment, the manufacturers say that is the low magnesium content, not between 0.8~1.2 (the actual measurement is 0.70~0.81 content), there is relationship between content and heat treatment on the quality of magnesium?

- It doesn't matter.6061 belongs to Al-Mg-Si wrought aluminum alloy. Hardness is not up to the mark. It may be that magnesium and silicon (of course, other trace elements) do not meet the requirements at the same time, or they may be caused by improper heat treatment process.The hardness after welding may be low, but the heat treatment is more trouble, after all, there is no other soft, there is a problem, heat treatment after deformation, processed into finished products and how to solve the problem of deformation, the wall thickness is too thin.The difference between the 6061 aluminum state T6 and T651 is in general, the internal stress of T6 will be relatively large, machining deformation, the most suitable processing condition should be T651, he is drawn on the basis of T6, eliminate the internal stress and the main alloy element 606 Aluminum Alloy is magnesium and silicon, and the formation of Mg2Si phase.

- Q: 6063, aluminum pipe bending performance, hardness of the best value?

- Three is energy-saving advantages: air conditioner indoor machine and outdoor machine connection pipeline, heat transfer efficiency is lower, more energy saving, or, the better insulation effect, the more power saving.Four is the bending performance, easy installation and removal

- Q: Are aluminum pipes suitable for wastewater treatment plants?

- Aluminum pipes are indeed a suitable choice for wastewater treatment plants. Their lightweight and corrosion-resistant nature make them perfect for environments where exposure to corrosive substances in wastewater is probable. Moreover, the installation and maintenance of aluminum pipes are hassle-free, resulting in reduced costs and effort for operating the wastewater treatment plant. However, it is crucial to consider several factors, including the type of wastewater being treated, the concentration of chemicals, and the plant's operating conditions, to determine if aluminum pipes are the best fit. Consulting experts and engineers in the field is highly recommended to select the most suitable materials for a specific wastewater treatment plant.

- Q: Is it better to choose a radiator, a copper tube or a steel tube?

- The radiator on the computer is copper, should be copper better?

- Q: Are aluminum pipes suitable for paper mills?

- Yes, aluminum pipes are suitable for paper mills. Aluminum is highly resistant to corrosion and can withstand the harsh chemicals and high temperatures often found in paper mills. Additionally, aluminum pipes are lightweight, making them easy to install and maintain in the industrial setting of paper mills.

- Q: How do aluminum pipes perform in salty environments?

- Aluminum pipes perform quite well in salty environments due to their natural resistance to corrosion. Unlike other metals, aluminum forms a protective oxide layer when exposed to air, which acts as a barrier against saltwater. This oxide layer prevents the metal from corroding and minimizes the effects of saltwater on the pipes. However, it is important to note that prolonged exposure to high concentrations of saltwater can still lead to some corrosion over time. Therefore, regular maintenance and inspections are recommended to ensure the longevity of aluminum pipes in salty environments.

- Q: Can aluminum pipes be used for roller coaster constructions?

- Yes, aluminum pipes can be used for roller coaster constructions. Aluminum is a lightweight and strong material, making it suitable for creating the structural framework of roller coasters. It offers various advantages such as corrosion resistance, durability, and ease of fabrication. Additionally, aluminum's high strength-to-weight ratio helps reduce the overall weight of the roller coaster, allowing for faster speeds and smoother rides. The flexibility of aluminum also allows for intricate designs and precise engineering. Therefore, aluminum pipes are a popular choice for roller coaster constructions in the amusement park industry.

- Q: Is the cold storage iron tube good or the aluminum tube good?

- The advantages of multi row steel aluminum parallelism of aluminum heat exchange faster than steel refrigeration so faster and almost cost steel row because aluminum does not rust so late without steel row do antirusting maintenance

- Q: Are aluminum pipes suitable for high-speed train tracks?

- No, aluminum pipes are not suitable for high-speed train tracks.

Send your message to us

Color Coated Aluminum Pipes with Blue Aluminium Coils for ACP Top Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords