Geocells Suppliers UK - Black PP Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Black PP Geogrid Description:

Black PP Geogrid is with polypropylene, high density polyethylene as raw materials, made by special extrusion, two-way stretch.It Can reduce structural fill, uniform load distribution, and has high two-way tensile modulus and tensile strength, high mechanical damage ability, endurance ability

Main Features of Black PP Geogrid :

Black PP Geogridcan be used to enhancement of permanent bearable toft including roads and railways embankment, slopes, tunnel, airfields, parks, docks and ground which cargo lays on and their main usage are as follows:

Enhance the bearing capacity of road foundation and extend the duration of roads.

Prevent road surface from collapse, crack and being dirty.

Be convenient for construction, timesaving and cut down the cost of maintenance.

Prevent tunnel from crack occurring

Further solidity slopes to proof water and soil from losses.

Reduce the surface thickness of the ground.

Consolidate the net for growing grass on the slopes so as to stabilization surrounding virescence.

Be used for artificial top net of mines instead of metal ones.

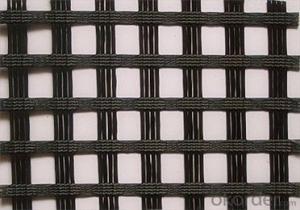

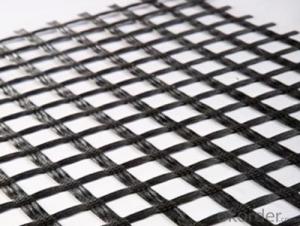

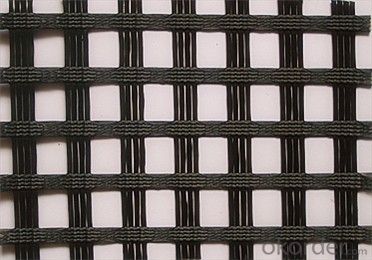

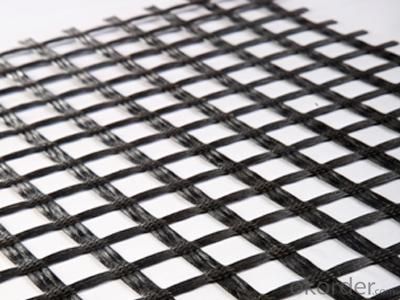

Black PP Geogrid Images

Black PP Geogrid Specification:

| Specifications | Tensile strength(KN/m) | Tensile strength at 2% elongation | Tensile strength at 5% elongation | Nomianal elongation | Products in the range of coal mine | Max peel strength at welding point | ||

| GSJ30-30 | ≥30.0 | ≥10.0 | ≥20.0 | ≤12 | Fire out time from outer flam(s) | Surface resistivity | ≥30.0 | |

| GSJ40-40 | ≥40.0 | ≥20.0 | ≥25.0 | ≤3 | <1×109 | |||

| GSJ50-50 | ≥50.0 | ≥17.0 | ≥34.0 | |||||

| GSJ60-60 | ≥60.0 | ≥22.5 | ≥40.0 | |||||

| GSJ80-80 | ≥80.0 | ≥28.0 | ≥56.0 | ≤13 | ||||

| GSJ100-100 | ≥100.0 | ≥35.0 | ≥70.0 | |||||

| GSJ120-120 | ≥120.0 | ≥60.0 | ≥90.0 | |||||

| GSJ150-150 | ≥150.0 | ≥52 | ≥104.0 | |||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: The difference between polyester glass fiber cloth and glass geogrid

- Hello, this is two different products

- Q: Are geogrids suitable for use in soil reinforcement for pipeline crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline crossings. They provide effective reinforcement by distributing loads and improving soil stability, reducing the risk of settlement or failure. Geogrids are designed to withstand high tensile forces and can enhance the performance and longevity of pipeline installations in various soil conditions.

- Q: What are the design considerations for geogrid-reinforced slopes?

- Some of the design considerations for geogrid-reinforced slopes include the slope stability analysis, selection of appropriate geogrid material and properties, determining the required strength and stiffness of the geogrid, proper installation techniques, and considering the long-term durability and maintenance requirements of the reinforced slope.

- Q: Are there any specific maintenance requirements for geogrids?

- Yes, geogrids have specific maintenance requirements. They should be inspected regularly for any signs of damage or deterioration, such as tears, fraying, or disintegration. If any issues are found, appropriate repairs or replacements should be made promptly to ensure the geogrid's effectiveness. Additionally, geogrids should be kept clean and clear of any debris or vegetation that could impact their performance.

- Q: How do geogrids enhance the performance of geocomposite drainage systems?

- Geogrids enhance the performance of geocomposite drainage systems by providing structural reinforcement and preventing the formation of localized stress points. They distribute the load more evenly, increase the overall stability and strength of the system, and minimize the risk of soil settlement. Additionally, geogrids help to improve water flow and drainage efficiency, reducing the likelihood of clogging and ensuring the long-term effectiveness of the geocomposite drainage system.

- Q: Do geogrids provide reinforcement to geosynthetic asphalt liners in reservoirs?

- No, geogrids do not provide reinforcement to geosynthetic asphalt liners in reservoirs.

- Q: What are the cost considerations for using geogrids in construction projects?

- Some cost considerations for using geogrids in construction projects include the initial cost of purchasing and installing the geogrids, the potential cost savings in terms of reduced excavation and material requirements, the long-term durability and maintenance costs, and the overall benefits and value that geogrids can provide to the project.

- Q: What are the factors that affect the creep behavior of geogrids?

- There are several factors that can affect the creep behavior of geogrids. These include the type and quality of the geogrid material, the load applied to the geogrid, the duration of the load, the temperature and moisture conditions, and the installation and construction methods used.

- Q: Can geogrids be used in soft soil conditions?

- Yes, geogrids can be used in soft soil conditions. Geogrids are often used in such conditions to improve the stability and load-bearing capacity of the soil. They are designed to provide reinforcement and prevent soil movement, making them an effective solution for soft soil conditions.

- Q: How do geogrids help in reducing the environmental impact of construction?

- Geogrids help in reducing the environmental impact of construction by providing soil stabilization and reinforcement, reducing the need for excessive excavation and material usage. This results in minimized disturbance to natural habitats, reduced waste generation, and lower carbon emissions, ultimately promoting sustainable construction practices.

Send your message to us

Geocells Suppliers UK - Black PP Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords