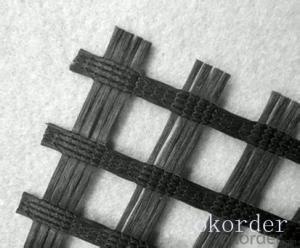

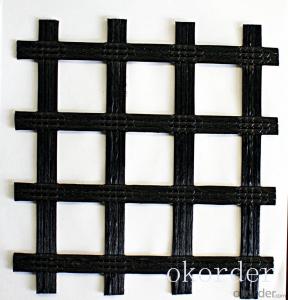

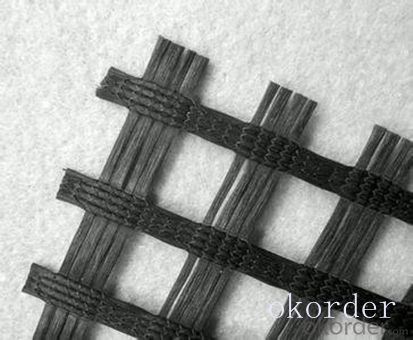

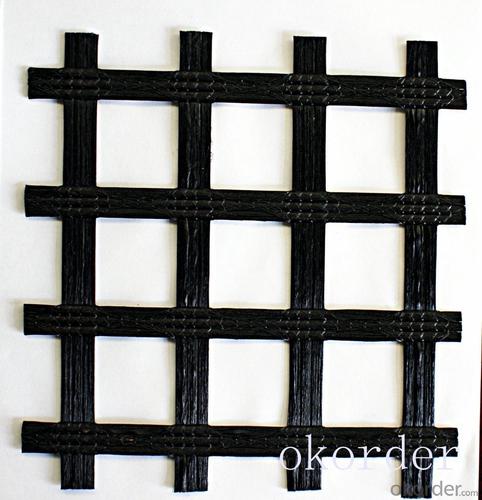

Fibreglass Biaxial Geogrids for Jetties, Roads, and Tunnels - Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

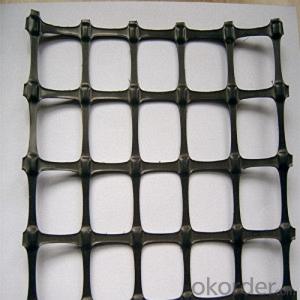

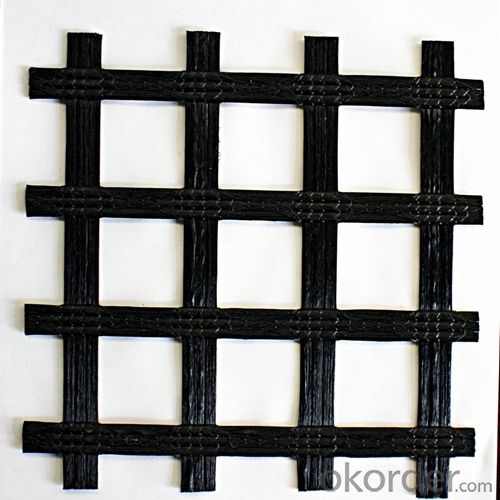

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

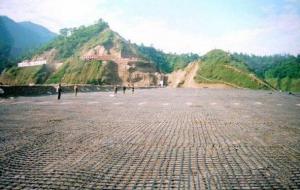

In case of water streams construction, geogrid application allows planting trees and shrubs along the banks protecting them from ablation. Geogrids are an economical solution for filling water stream base and creates almost an ideal surface for laying down a water resistant layer.

Geogrid protects channel slopes, provides resistance and stability, protecting this object from erosion. Additional advantage is drainage along channels. Geogrid application considerably reduces losses, connected with fall of ground, landslides and deformation of slopes.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile manufacturers which good? Where is the best geotextile, geotextile manufacturers

- Nonwoven and woven composite geotextiles:The non-woven fabric is woven with the polypropylene filament woven fabric, and the non-woven fabric is woven with the plastic braiding.

- Q: Are geogrids suitable for reinforcing embankments?

- Yes, geogrids are suitable for reinforcing embankments. Geogrids are specifically designed for soil reinforcement and stabilization purposes. They can effectively distribute loads and improve the stability and strength of embankments, preventing soil erosion and potential failure. Additionally, geogrids are easy to install, cost-effective, and have a long service life, making them a reliable choice for reinforcing embankments.

- Q: I am a quality inspector, I would like to know what is the standard implementation of Geogrid

- 4:YT030 geotextile effective aperture measuring instrument5:YT040 type dynamic testing instrument for geotextiles6:YT050 type geotextile wear tester

- Q: Are geogrids resistant to UV degradation?

- Yes, geogrids are generally resistant to UV degradation. They are designed to withstand prolonged exposure to sunlight without significant degradation or loss of strength.

- Q: How to calculate the amount of geogrid works under what circumstances need to lay geogrid

- According to the road area, [136] asphalt pavement often laying geogrid [0772], [6164] but if the asphalt is thin, can not. Also like municipal roads will generally be used.

- Q: What are the specifications of fiberglass geogrid for Asphalt Pavement

- Bidirectional geogrid, fiberglass geogrid, steel plastic fine

- Q: Are geogrids effective in stabilizing embankments for pipeline crossings?

- Yes, geogrids are effective in stabilizing embankments for pipeline crossings. Geogrids provide reinforcement and increase the stability of the soil, preventing erosion and potential slope failures. They distribute loads and reduce settlement, ensuring the integrity of the embankment and protecting the pipeline.

- Q: Are geogrids suitable for use in reinforced retaining walls?

- Yes, geogrids are suitable for use in reinforced retaining walls. Geogrids provide effective reinforcement by improving soil stability, preventing wall failure, and increasing overall structural integrity of the retaining wall. They enhance the load-bearing capacity of the wall and help distribute the forces exerted by the retained soil, making it a reliable and durable solution for reinforced retaining walls.

- Q: What is the meaning of reinforced subgrade? Is there a geogrid type on the road?

- Reinforced embankment subgrade usually with earthwork material, application is very flexible, such as mesh woven with the willow branches can also do the laying of reinforcement materials in the soil, reinforced net can also, but each has advantages and disadvantages, according to the actual needs of the design.

- Q: Do geogrids reduce the amount of fill material required?

- Yes, geogrids can reduce the amount of fill material required. Geogrids are used to reinforce soil and distribute loads, allowing for the construction of structures with less fill material. This can lead to cost savings and reduced environmental impact.

Send your message to us

Fibreglass Biaxial Geogrids for Jetties, Roads, and Tunnels - Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords