Manufacture Of Rotary Transportation Pump

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10000 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of rotary transportation pump:

Rotary transportation pump is the key equipment for the mechanise production of grc

products, this is a new technique which is referenced from foreign well rounded technique, developed unaided, and suit for the sweeping production of grc. It had used wireless actiyator and grc carriers feeder, it have so many excellences such as feeder continuous, easy handle, high production efficiency, good roduction quality, etc.

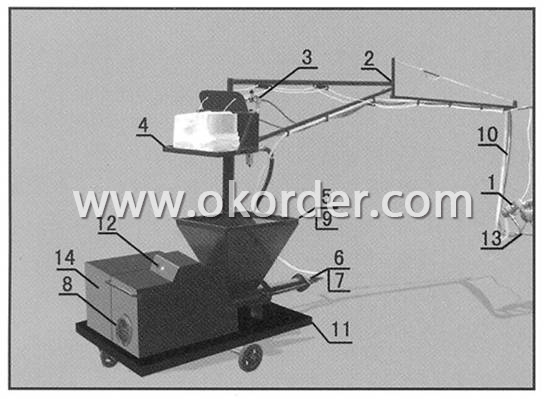

Construction and function of rotary transportation pump:

1. Gunjet: you can select coaxial gunjet or heteraxial gunjet or premixed gunjet or long gunjet as your need.

2. Cantilever: cantilever have two parts, each part is 2 meters, total is 4 meters, so, it can work in a round area, which use eject machine as center and have 4 meters radius. It used for hang the material pipeline and constringented air pipeline, and transfer them to gunjet position.

Working instruction for rotary transportation pump

3. Air element: it contain the air filter and reductor and oil mist element etc. It is used to filtrate the constringented air and adjust the constringented air pressure and lubricate the pneumatic motor.

4. Yarn spindle platform, it can be revolving with cantilever synchronous to avoid yarn twist. Tundish: it is used to reserve material.

5. Spindle: it is a key element with rotor for ls002, their relative movement can export the products continuously.

6.Rotor: it is a key element with spindle for ls002, their relative movement can export the products continuously.

7. Wireless actiyator: this is the power origin, you can adjust the products sendout via it’s rotate speed.

8. Beater: churn the material and send it to the entrance of spindle and rotor.

9. Material pipe: it can make the material transferred from assistant spindle/rotor to gunjet.

10. Pedestal: it is moveable.

11. Control equipment: use this to control the machine.

12. Windpipe: supply constringented air for gunjet.

13. Cover: protect the wireless actiyator

- Q: GRC light partition board installation scheme for construction of hydropower pipelines

- In the installation of water tanks, magnetic pots, electrical switches, sockets, wall lamps and other water appliances, according to the requirements of the size of the chisel hole (not tick), can not use heavy hammer, so as not to shock the wall panels. After the pipeline is buried, immediately cement mortar, putty, plug and scrape. For larger, heavier weight apparatus such as the power box is to cut holes according to size requirements (not, then drove) wedge or steel embedded parts with cement mortar pouring plug, after the installation of 7d.

- Q: What is the standard value of GRC durability?

- The durability of truly qualified GRC products is almost the same as that of concrete (usually 50 years).

- Q: How to identify new wall panels

- In accordance with the different materials of new wall panels can be divided into three types: (1) GRC new wall, the main material is decreasing sulfur aluminum acid salt cement, coal ash, ceramsite, perlite, mesh or steel mesh; (2) kneading cement wall, the main material is ordinary cement, coal ash, washed; (3) high strength cement wall, the main material is magnesium chloride and Magnesium Oxide, commonly known as magnesite, alkali mesh.

- Q: GRC jet equipment prices?

- This thing is high and low, automatic and semi automatic, the selected category.

- Q: Are there any national standards (strength, protection grade) in the case of GRC materials used as equipment and outdoor rooms?

- There are standards mentioned upstairs, but there is no standard for GRC materials used in outdoor rooms

- Q: Daming Palace building materials wholesale GRC European style component where?

- To many, I suggest you find well-known high, customized, are generally required to design CAD drawings, people help you do, we have done before the project is in Qinglong

- Q: What are the surface treatment methods of GRC?

- 1, waterproof and antifouling treatment of GRC component surface. : for already made good decorative products, we need to GRC products surface treatment, so that the surface has a certain waterproof and antifouling properties, has been a longer use time and landscaping effect.2, through the mill, sandblasting, pickling, stone, coloring, spraying, the surface of GRC aggregate exposed or get other effects, the GRC has a special surface decorative effect. It may also be painted on the surface after the GRC has been installed on the wall.

- Q: What material is GRC?

- GRC also known as GRC components, and its Chinese name is glass fiber reinforced cement, simple to say that the external wall decoration materials, or wall decoration hanging board, mainly used in European style building exterior wall decoration. There are many kinds of GRC at present, such as GRC relief, GRC column, GRC window sleeve, GRC line and so on.If the project is wide Friends of the GRC can do in the engineering goods accessories temporary factory, which can be mounted.

- Q: How many useful years does the GRC art component have?

- GRC components of the service life and its own quality and workmanship are related, quality and workmanship better, of course, the longer the use of the industry average is 30 years, there are 50-70 years of use.

- Q: GRC what's the use of imitation wood?

- GRC finished generic board you can take it as a decorative building materials to use ah, it is a kind of artificial materials only, don't see it's amazing, generally used in building exterior decoration.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang PORT |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Manufacture Of Rotary Transportation Pump

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10000 Sets Per Year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches