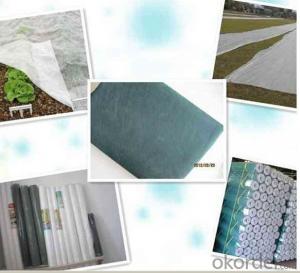

Beige PP Spunbonded Nonwoven Geotextile Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Beige PP Spunbonded Nonwoven Fabricis used to protect the crops in agriculture UV resistance masterbatch could be added 1%~8%. It can protect the vegetable crops and new lawns against extreme weather, animal and insect damage, yet allows light, water and air to penetrate, creating protected growing conditions..

Specification of Beige PP Spunbonded Nonwoven Fabric:

Width : From 1~ 2.4m

Length: 50-100m as customer requests.

Weight : 17gsm~ 80gsm

Color : black ,white ,other colors are available

Packing of Beige PP Spunbonded Nonwoven Fabric

Each roll is wrapped in a plastic bag with label specification with paper tube inside .

Superiority

1.Free Samples

2.Factory Supply

3.Competitive Price With High Quality

4.More than 20 years experience

- Q: Do you have a geotextile

- Summer to sunscreen, winter to antifreeze. The So summer not only to be able to block the sun, but also breathable. The Winter to warm good. The To achieve such a request, no matter what you can make the material. The

- Q: What are the different geotextile filter criteria?

- The different geotextile filter criteria include permeability, retention, durability, and compatibility. Permeability refers to the ability of the geotextile to allow water to pass through while retaining soil particles. Retention is the capability of the geotextile to prevent soil particles from passing through, ensuring effective filtration. Durability assesses the geotextile's resistance to physical and chemical degradation over time. Compatibility refers to the geotextile's compatibility with the soil and other materials it is in contact with, ensuring long-term effectiveness.

- Q: How do geotextiles contribute to groundwater recharge projects?

- Geotextiles contribute to groundwater recharge projects by providing a permeable barrier that allows water to infiltrate into the ground while preventing soil erosion and sedimentation. They act as a filter, allowing water to pass through while retaining fine particles, thus enhancing the recharge of groundwater aquifers.

- Q: The amount of geotextile drainage of the drainage pipe, as well as the amount of gravel block ye count

- Calculate the surface area of the water pipe, and then add a 10% of the amount, is the amount of geotextile, Huazhi geotextile material manufacturers to answer

- Q: What are the key factors affecting the filtration performance of geotextiles?

- The key factors affecting the filtration performance of geotextiles include the permeability of the geotextile, the pore size distribution, the thickness and weight of the geotextile, the hydraulic gradient, and the particle size of the soil being filtered.

- Q: How long do geotextiles last?

- Geotextiles typically have a lifespan of 20 to 50 years, depending on factors such as the type of material used, environmental conditions, and the intensity of use.

- Q: How are geotextiles tested for filtration efficiency?

- Geotextiles are tested for filtration efficiency using standardized laboratory tests, such as the ASTM D 4491 test method. This involves measuring the flow rate of water through the geotextile and analyzing the retention of particles of different sizes.

- Q: Are geotextiles resistant to hydrolysis?

- Yes, geotextiles are generally resistant to hydrolysis. Geotextiles are engineered materials made with synthetic fibers, such as polyester or polypropylene, which are resistant to the chemical breakdown caused by hydrolysis. This resistance allows geotextiles to maintain their strength and durability when exposed to moisture and water over time.

- Q: What are the key factors affecting the tensile strength of geotextiles?

- The key factors affecting the tensile strength of geotextiles include the type and quality of the materials used, the manufacturing process, the thickness and weight of the geotextile, the orientation and arrangement of the fibers, as well as environmental factors such as exposure to sunlight, moisture, and temperature.

- Q: What are the factors to consider when designing geotextile-reinforced pavements?

- When designing geotextile-reinforced pavements, several factors need to be considered. Firstly, the type and characteristics of the geotextile, such as its tensile strength, permeability, and durability, are crucial for ensuring its effectiveness in reinforcing the pavement. Secondly, the properties of the soil and subgrade, including their bearing capacity, moisture content, and stability, must be taken into account to determine the appropriate geotextile design. Additionally, the traffic load and volume, as well as the climate conditions of the project area, play a significant role in selecting the suitable geotextile and pavement thickness. Proper installation techniques, quality control measures, and regular maintenance should also be considered to ensure the long-term performance of geotextile-reinforced pavements.

Send your message to us

Beige PP Spunbonded Nonwoven Geotextile Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords