Bamboo / Wood Acoustic Panel for Wall / Ceiling – Eco Nano Perforation Interior Decoration Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Arc i200TM Acoustic Series

Description

Absorption performance is achieved with beauty and innovation with Arc i200™. The Arc i200™ Acoustic Series is designed to achieve performance acoustic requirements, using a variety or perforations and backing systems. The Arc i200™ Acoustic Series is ideal for controlling sound absorption in a performance requirement environment while achieving harmonious, natural aesthetics in wall or ceiling coverings. The Arc i200™ Acoustic Series are the most sustainable, wood, classified, panels in the world and can achieve the highest performance, ideal for any interior design.

| Material | Dimensions | Surface | Color |

Solid engineered bamboo Non-Toxic, Low V.O.C. adhesives (LEED Credit Certified) Fire Rating: International Class B China Class B1

| Thickness: 9.5mm, 13mm 19mm,25mm Width x Length 610mm x 1220mm 1220mm x 2440mm Custom Available | Grain: Vertical / Edge Grain Horizontal / Flat Grain | Natural color Custom stained |

| Backing | Acoustic | Acoustic Treatment | Installation |

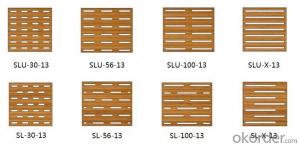

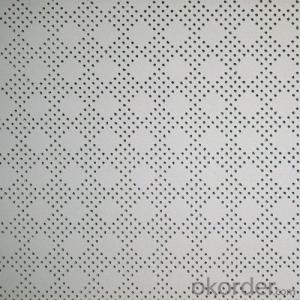

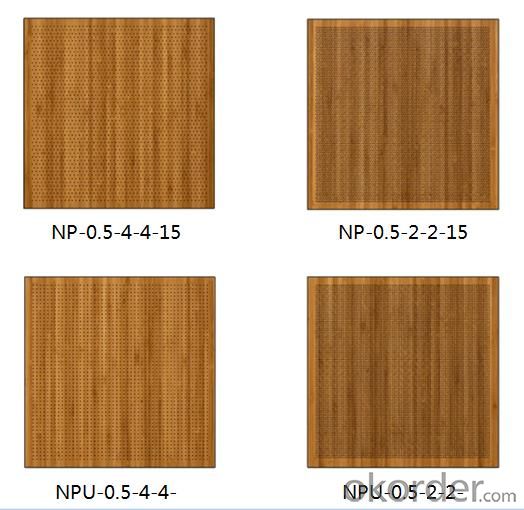

Fabric PET No backing | Up to 0.8 NRC. Can achieve higher with custom setup | Perforation Diameter: Nano, Micro, 2.0ø~6.0ø, Custom Standard open space: 6%, 10%, 20%, 40% Custom patterns in coverage are available.

| Lap-Joint, T+G, Flush, Custom Standard Z-Clip gravity system Supplied by us. |

Arc NP-i200™ - Nano Perforation

Note

1.Standard panel sizes, 610*1220, 1220*2440 mm (width* length). Custom sizing is available, please inquire.

2.Edge profile subject to product dimension.

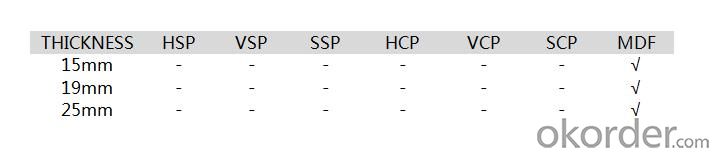

3.Available lay-ups for different thickness.

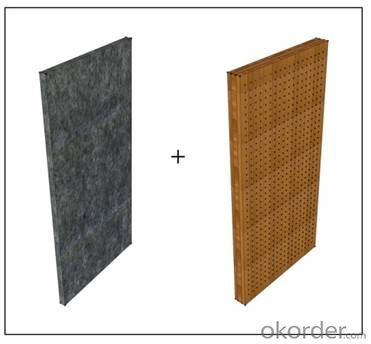

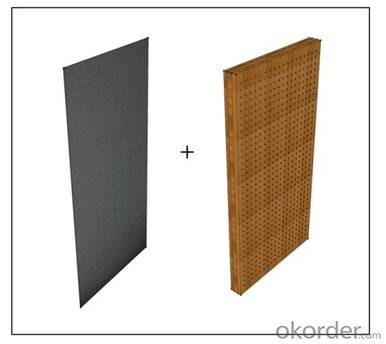

Arc i200™ Acoustic Backing

Description

The acoustic performance of architectural cladding is a result of the combination of materials and their final assembly. Acoustic backing systems are integrated with bamboo materials to support the achievement of desired acoustic performance. Our products are tested to ensure predictable performance, allowing acoustic engineers to design according to their requirements and for standard applications to have the acoustic result desired.

Details

PET Backing

Non-toxic, acoustic and thermal-insulation backing, provides acoustic performance of up to 0.8 NRC as a standalone component. PET combined with it materials is the highest performing and sustainable option for architectural panels. PET panels can achieve the China B1 Fire Rating and International Class B.

Acoustic Felt

Sound-absorbing black felt is a very thin non-woven fabric, with the thickness being 0.2mm and the average weight of 47g/m2. This fire rated felt can achieve China Class B1 and ASTM E84 – Class B.

Arc i200™ Acoustic | Installation

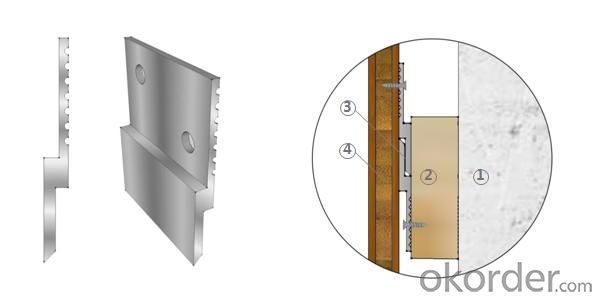

Arc i200™ Acoustic Cladding are installed using Z-Clip Systems.

To maximize acoustic performance, first fix wall blocking (see required thickness for acoustic performance in architectural drawings) spaced at 600mm center, over the area to be clad. The aluminum Z-clip track is fixed in place to create air flow between the panels and the wall. Fibrous insulation may be required, installed by fitting between the wall blocking and aluminum z-clip tracks. as an additional acoustic absorber, prior to installing Arc S-i200™ Panels. Arc S-i200™ Panels are fit by connecting the Z-clips on the panel to the z-clip on the wall. See 3-Part Specification sheet for further details.

Z-Clip Fastener Cross-section of installed system

Z-Clip Fastener: Projection 6.35mm (1/4”);Lift off 6.35mm (1/4”)

Cross-section of installed system: 1.Concrete Wall; 2.Wood Blocking; 3.Z-Clip System; 4.Panel with backing

1. The “Lift-Off” is the amount needed to raise the panel over its resting height to mount the panel.

2. The “Projection” is the distance that the panel sits out from the wall.

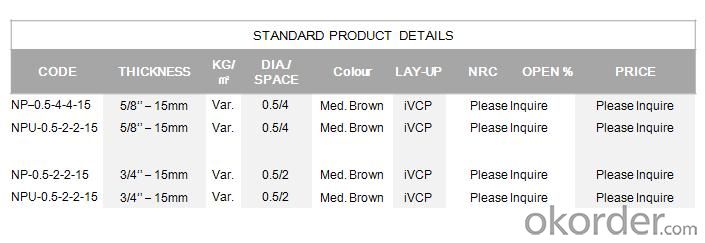

Arc i200™ Acoustic Series | Standard Product Details

Panel Details:

1.All pricing is based on net coverage and includes standard packaging.

2.Minimum quantities may be required for certain panel dimensions and/or colours. Please Inquire.

3.All pricing is based on med. brown (carbonized) color, Please see colour chart for available standard colours. Special colours are available, please inquire.

4.Certain series panels are available in a vertical and horizontal grains only. See lamination lay-up chart for details.

5.Custom thickness, widths, lengths are available, please inquire.

Acoustic Performance:

1.All acoustic ratings are based on the panel itself in a controlled test lab. Any special conditions may require independent testing to ensure the requirements of the acoustic performance are met.

2.Special acoustic requirements can be achieved by custom acoustic assembly systems.

Backing Details:

1.PET ......................................................... Please inquire

2.Felt .......................................................... Please inquire

Finish Details:

1.All products are finished with premium finish treatments, designed for the materials.

2.Standard finishes include closed and open pore options, matte, and semi-gloss treatments. Special finishes are available, please inquire.

3.The interior finishes are environmentally friendly and can contribute to a projects LEED or other environmental certifications. Please inquire.

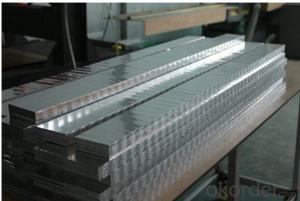

Packaging Details:

1.Standard packaging: Panels/planks are stacked with EVE protective film interleafing and strapped. Secured on each side with 6.35mm plywood and blocked for shipping protection. Each package is wrapped with PP weather protective covering, and palletized.

2.Optional ECO packaging available. Please inquire.

3.LCL shipments require increased plywood crating with micro-foam interleafing.

4.International shipments ....................................... Please inquire.

5.Special packaging ............................................... Please inquire

Shipping Details:

1.Mainland China.................................................... Please inquire

2.Other Country or Area.......................................... Please inquire

Delivery Details:

1.13mm- stocked Med. Brown (carbonized) ............Please inquire

2.Other dimensions, colors and lay-ups ................45days + shipping

Notes:

1.All panel lengths over 1220*2440mm....................Please inquire

2.Limitations may apply to certain lay-ups.

3.All sizes subject to 0.0625 inch (1.3mm) tolerance.

4.Installation of material constitutes acceptance. It is the customer's responsibility to check received product(s) from us before signing the freight carrier's paper work to ensure no damage has occurred to the finished product(s) during transit. If the customer signs off on the delivered product(s) before checking finished product(s) and damages have occurred due to transportation, It will not be our responsibility to replace any damaged product(s).

Grain Surface Detail

Vertical

Horizontal

Strand

Vertical Series

VSP – Vertical Solid Ply

Unidirectional Laminated Ply(s)

VCP –Vertical Cross Ply

Cross Laminated Ply(s)

Horizontal Series

HSP – Horizontal Solid Ply

Unidirectional Laminated Ply(s)

HCP – Horizontal Cross Ply

Cross Laminated Ply(s)

Strand Series

SCP – Strand Cross Ply

Cross Laminated Ply(s)

- Q: What kind of sound-absorbing panels are there in the cinema wall?

- Wood sound-absorbing panels

- Q: What is aluminum alloy sound - absorbing board construction technology

- Type, leaving seam type, aluminum type H keel aluminum π keel and so on

- Q: Can green wood do sound-absorbing panels?

- Not only can be used indoors, can also be used in outdoor, outdoor garden.

- Q: Does the sound-absorbing panel ceiling fit?

- If it is polymer material, do not need to consider

- Q: How to clean up the polyester fiber sound absorbing board

- Grease and rust, use a special degreasing, rust cleaning agent (you can choose the car with the oil derusting agent)

- Q: How is the sound-absorbing board on the wall?

- Wooden sound-absorbing panels covered walls must be installed according to the design drawings or construction requirements of the keel, and the keel leveling treatment. Keel surface should be smooth, smooth, no rust, no deformation.

- Q: What are the advantages and disadvantages of mineral wool sound-absorbing panels?

- At the same time mineral wool board also has a good thermal insulation properties, mineral wool board, the average thermal conductivity is small, easy insulation, and mineral wool board is the main raw material is mineral wool, melting point up to 1300 ℃, and has a high fire performance.

- Q: What is the polyester fiber sound insulation board decoration precautions

- Polyester fiberboard with toughness and tensile strength, available clamp or hanging pieces directly connected with the board edge.

- Q: Is the polyester fiber sound absorbing board environmentally friendly?

- Polyester fiber sound-absorbing panels called polyester fiber decorative sound-absorbing panels, is a polyester fiber as raw materials made by hot-pressing sound-absorbing function of decorative materials.

- Q: What is the principle of sound-absorbing panels?

- Similar to the needle surface (like a lot of knot tied into a bundle to form a "plane") theory is the best sound-absorbing material, acoustic laboratory is so designed, the principle is to reach the "needle" surface after the sound, constantly Inward reflection, and never reflected out, this surface can be the same as the black hole to the sound (and light) completely absorbed. This is the silencer used in the "sound-absorbing split." But this method is expensive, and the general studio and HIFI listening room does not need such a complete sound-absorbing, so are using the front material.

Send your message to us

Bamboo / Wood Acoustic Panel for Wall / Ceiling – Eco Nano Perforation Interior Decoration Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords