Aluminum honeycomb core &panels export service providers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

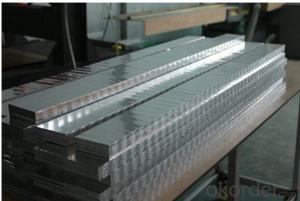

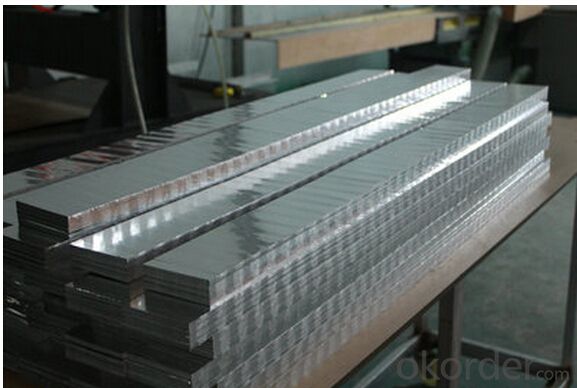

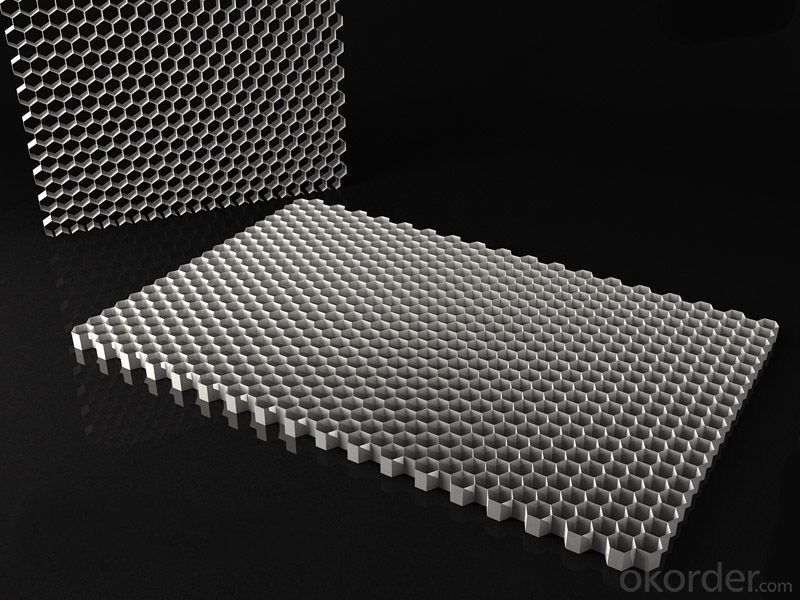

Aluminum honeycomb core profile:

Aluminum honeycomb core is bonded by a multi-layer aluminum foil, laminated, and then stretched expanded into regular hexagonal honeycomb core. Aluminum honeycomb core with a sharp, clear cell walls, no glitches, for high quality bonds and other uses across the core material.

Hexagonal honeycomb panels aluminum honeycomb core structure, each other to contain dense cellular beams like many unskilled laborer, dispersible bear the pressure from the direction of the panel, so that the plate by force, to ensure that the panel is in a larger area can maintain high level

Flatness. In addition, the hollow honeycomb can be greatly reduced thermal expansion of the plate body. Delivery form aluminum honeycomb core aluminum honeycomb stacked into blocks, strips and aluminum honeycomb core aluminum honeycomb core block after stretching.

Aluminum honeycomb core characteristics

★ made of metal, it is easy to recycle, green product;

★ light weight, high strength, rigidity and tear resistance;

★ excellent weathering performance: high temperature resistance, corrosion resistance, aging;

★ big plate, modulus uncertain, flatness;

★ superior bonding strength;

★ seams straight, easy to install;

★ fire retardant, sound insulation, heat insulation effect;

★ also has a strong decorative, easy processing, stable performance characteristics.

Aluminum honeycomb has many advantages

1. Strength higher: the honeycomb structure have become nature's most effective and rational structure, because of its geometry regular hexagon. This shape is well dispersed force suffered, and support each other, making it a perfect mechanical structure. Tubular honeycomb structure not have this advantage, on the one hand, it can not force a good round to pass out, the force is difficult to be dispersed; on the other hand, many small pipe bonding area is small , focused almost entirely on location in the circle and the circle of cut points, compared with the total adhesion area of one side of the hexagon, the intensity is much smaller. Tubular cellular easily break apart by hand, while the hexagonal honeycomb is difficult to separate them.

2. lighter: its hexagonal honeycomb structure with excellent mechanical for people to save a lot of raw materials under the premise of ensuring the strength, it can use thinner material, so that the lighter, it also means: hexagonal honeycomb more savings in raw material costs.

3. The insulation, sound insulation and better: As the hexagonal honeycomb less dense, heat transfer and sonic cell walls thinner, its insulation, noise performance are better than tube honeycomb.

4. The cross-sectional area smaller: Under the premise of the same aperture, the cross-sectional area of the hexagonal honeycomb is often less than half of tubular cell, which makes the occasion with beehives are air flow, hexagonal honeycomb shape can be more efficiently through more air flow to improve both efficiency and save energy.

5. The specific surface area is greater: in the same proportion, the hexagonal honeycomb has a larger surface area. When used as a catalyst or a honeycomb filter, the higher the efficiency of a hexagonal honeycomb.

6. The more beautiful and neat: with the progress of the production process, the hexagonal honeycomb arrangement may very neat appearance more beautiful, but it is difficult to arrange cellular tube is very neat appearance is relatively sufficient regularity.

Aluminum honeycomb core purpose

Decoration materials: aluminum honeycomb composite panel curtain wall, ceiling aluminum honeycomb composite panel, aluminum honeycomb anti-static flooring, wall aluminum honeycomb composite panel (electronic factory), aluminum honeycomb composite fire doors, marble composite aluminum honeycomb panels;

Household appliances: air conditioning cold catalyst network, refrigerator deodorant blocks, heaters lattice network, air purifiers and other air guide grid;

Lighting industry: all kinds of exhibition spotlights guide grating, lighting, traffic lights and other barrier;

Audio industry: tablet pronunciation board, long thin speakers, and small and medium traditional speakers, headphones, speakers, etc.;

Transportation: Railway train, car subway trains and ships, train doors, partitions and other decorating material;

Furniture industry: home furniture, office furniture, furniture and other exhibits, with moisture, decay, fire function, and its compressive strength, flexural properties much better than traditional timber.

Aluminum honeycomb core and edge thickness of aluminum prices based on length density.

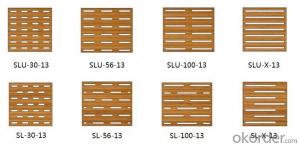

1, standard products:

Expand Size L≤1200mm and W≤2400mm, can be any thickness, any supply for a minimum thickness of 3mm, the maximum thickness of 560mm.

Two special products:

Other sizes can be customized, we can supply a maximum 2100mm long strip cut, expand the W direction up to 12000mm, L direction up to 1550mm honeycomb core.

3, error:

Cut more than 8mm thickness error bars of ± 0.125mm, 8mm or less cut strip thickness error was ± 0.2mm

Nominal density error of ± 10%

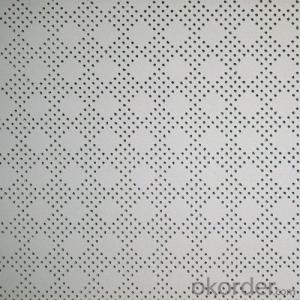

4, the surface

No special treatment, no oil, no glitches

5, quality

Our guarantee flatness of less than 0.3mm per m2 supplied.

Each batch of manufactured products inclusive of product quality certification, flatness test reports, packing slips and the like.

6, packaging

Wooden box or carton packaging

Expand the block between each piece of brown paper or foam separated to prevent end-use transit squeezed the cells leads to cellular deformation or rupture foil influence

- Q: What kind of sound-absorbing panels are there in the cinema wall?

- Fireproof polyester fiber sound absorption board

- Q: Can green wood do sound-absorbing panels?

- Can be processed into sound-absorbing panels, wooden ceiling, door frames, window frames, floor, baseboard, door, wall panels, waist lines, all kinds of decorative lines, curtains, blinds, blinds, fences, landscape and so on.

- Q: Classification of sound absorbing panels

- Polyester fiber sound-absorbing panels by the National Fire Detection Center on the fire parameters of the test, the results show that a better fire performance, in line with national standards GB8624B1 level requirements

- Q: How to clean up the polyester fiber sound absorbing board

- Grease and rust, use a special degreasing, rust cleaning agent (you can choose the car with the oil derusting agent)

- Q: How is the sound-absorbing board on the wall?

- Structure of the wall in accordance with the building code for pre-construction treatment, keel arrangement size and sound-absorbing panels must be adapted to the layout. Wood keel spacing should be less than 300mm, light steel keel spacing of not more than 400mm. The installation of the keel is perpendicular to the length of the sound absorbing plate.

- Q: What are the advantages and disadvantages of mineral wool sound-absorbing panels?

- Mineral wool board sound absorption and sound insulation often need to reduce the density, so that hollow; or punching, these methods will significantly reduce the strength of mineral wool board, resulting in easy to damage when lifting.

- Q: What is the production of wood sound-absorbing wallboard installation process

- The first light steel keel installation wall, with sound-absorbing panels professional aluminum keel playing light steel keel buckle installed aluminum keel sound-absorbing panels

- Q: Is the noise board the same as the sound-absorbing panel, what's the difference?

- Sound-absorbing panels are used to extend the sound space, there must be a gap. Role: noise reduction, elimination of echo, so that the sound more clear, suitable for high acoustics requirements of the place;

- Q: Is the polyester fiber sound absorbing board environmentally friendly?

- Polyester fiber sound-absorbing board safety performance in two aspects, on the one hand the excellent mechanical properties of materials, light weight, impact damage will not like some brittle materials such as perforated gypsum board and cement fiber pressure plate, etc. The block is in danger of falling. On the other hand is the release of harmful substances, the relevant state departments to detect, the formaldehyde emission standards require ≤ 1.5 ㎎ / 1, the test results for 0.05 ㎎ / 1. To meet the national standard GB18580-2001E1 level requirements, in line with the direct requirements for interior decoration.

- Q: What are the big brands of sound-absorbing panels?

- Armstrong

Send your message to us

Aluminum honeycomb core &panels export service providers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords