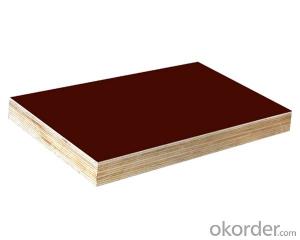

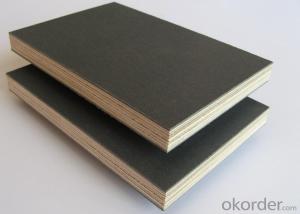

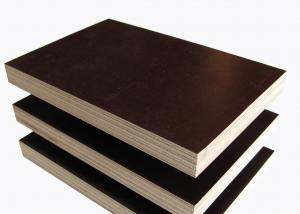

Bamboo Plywood Sheets - Brown Film Faced Plywood & Brown Marine Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

Film Faced Plywood are widely used in construction repeatly.

Characters:

Light, easy to install and disassemble; be used recyclely, waterproof.

Products Details:

Detailed Specification:

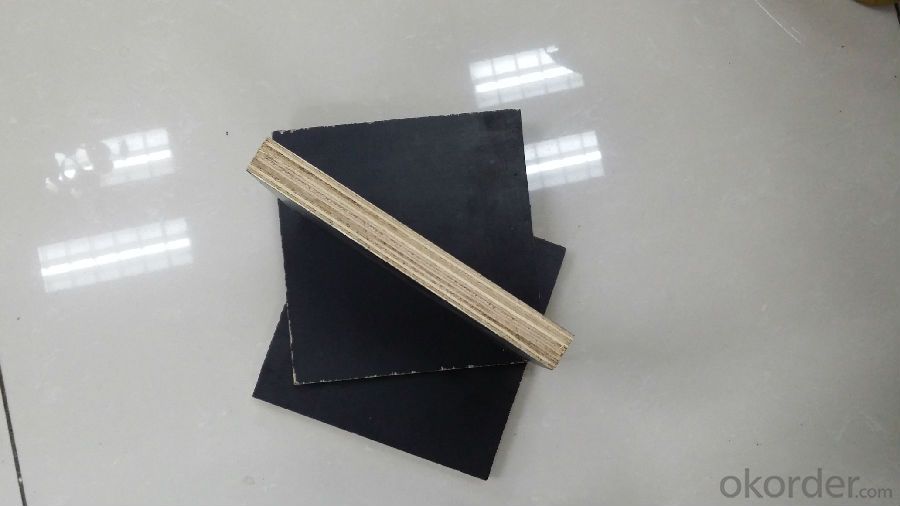

product name: Brown Film Faced Plywood

Size:1220x2440mm,1250x2500mm

Hot press: two times hot press

Thickness:9mm,12mm,15mm,18mm,20mm,21mm,25mm

Tolerance: +/-0.5mm

Core:Poplar,Eucalyptus,hardwood,combi

Film:brown with/without logo

Glue:MR,WBP(melamine),WBP(phenolic)

Grade:First class

Moisture:below 14%

Usage:outdoor,concrete forms,formwork,shuttering,construction,etc

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP:8 pallets/23m³

40’GP:16 pallets/45m³

40’HQ:18 pallets/57m³

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

FAQ:

Q1.How many times it can be used?

A1: It mainly depends on hotpress times, quality of raw materials and type of Glue. Normally, Melamine glue poplar core two times hot press film faced plywood can be used about 5-8times.

- Q: defects are divided into four grades

- , first class, second class, third, which, one, two, three for the general grade of the main plywood.

- Q: What is the composition of the plywood?

- Plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Hard fiber board is also a density board, but its density is above 0.80g / cm3. Divided into one side of the light, the other side of the textured side of the hard fiber board and two-sided hard fiber board two.

- Q: How do you choose plywood in plywood production?

- Several kinds of said in the "veneer", "slices", "veneer" are reflected in the "plaque" the basic characteristics. But can not be cedar plywood, ash willow plywood and other abbreviations, because these referred to as refers to the plywood panel, the floor by the cedar or Ash made.

- Q: What harm does the plywood factory work?

- Plywood using adhesives, containing benzene, toluene, xylene and other solvents, with the corresponding occupational hazards

- Q: A brief introduction to plywood

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: The density of the plywood is greater than that of the same kind of wood

- As the plywood from the criss-cross the preparation of the veneer, the thermal conductivity is lower than the same species of wood

- Q: Multilayer board, also known as three plywood and plywood

- the plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q: Distinguish between multilayer boards and plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Decorative veneer veneer plywood features

- Decorative veneer veneer plywood is one of the most commonly used materials for interior decoration

Send your message to us

Bamboo Plywood Sheets - Brown Film Faced Plywood & Brown Marine Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords