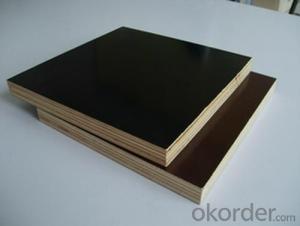

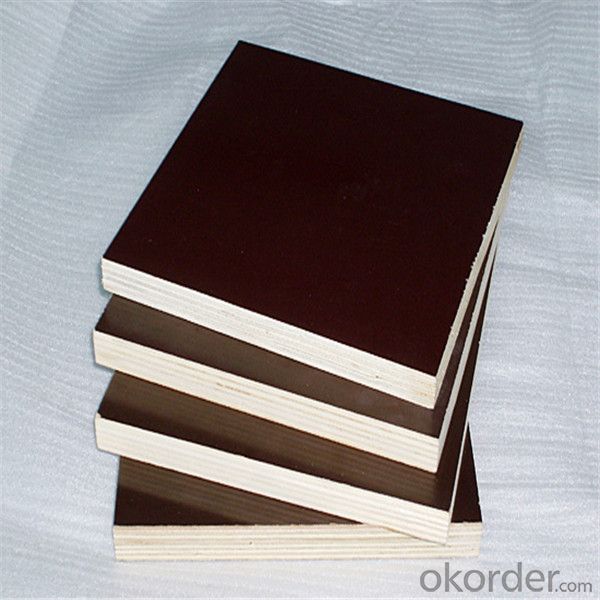

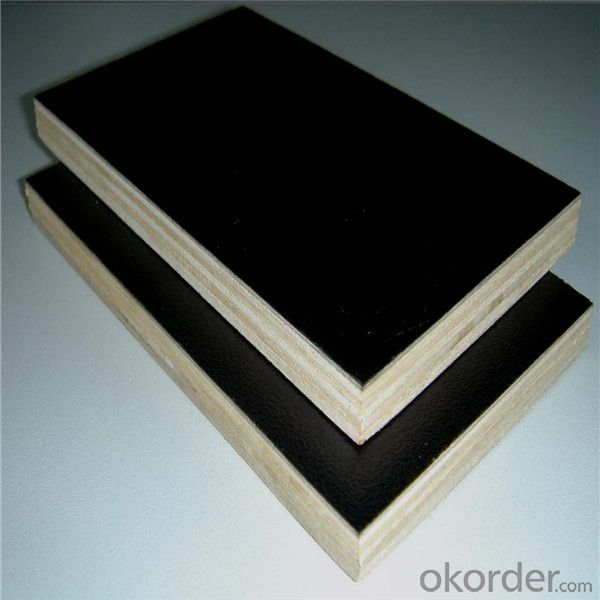

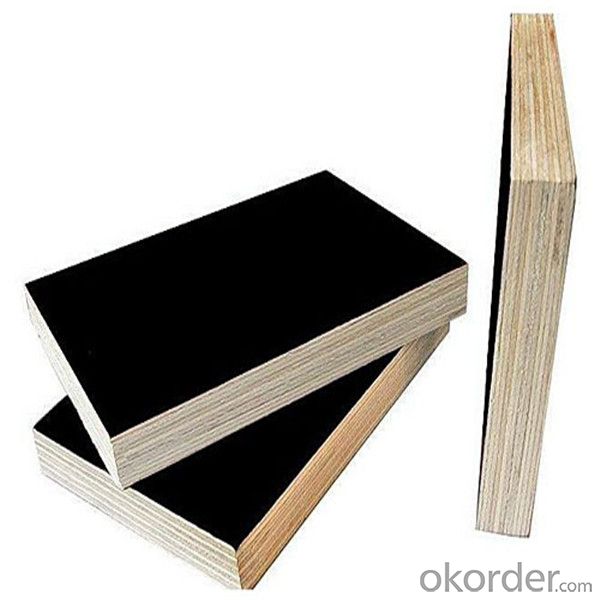

Construction Plywood Sheet Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION

| Type: | Plywoods | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CNBM |

| Model Number: | GB18580 | Usage: | Outdoor | Grade: | First-Class |

| Main Material: | Poplar | Formaldehyde Emission Standards: | E1 | Plywood Type: | as request |

| Color: | black/brown | Material: | Wood | Wood style: | Panel |

SPECIFICATION

Origin Place | Shandong Province ,China |

Brand Name | CNBM |

Size | 1220*2440mm, 1220*2500mm,1250*2500mm |

Core | Poplar, birch, hardwood, combi |

Glue | MR,WBP,melamine |

Thickness | 3-35mm |

Moisture | 4%-16% |

Certification | ISO9001:2000, CE, |

Production capacity | 10000 Piece/ Day |

Packing | Inner with plastic bag, outer is covered with the carton and plywood, and steel tape for strength |

Payment terms | TT or L/C at sight |

Delivery time | 35 days after receiving the deposit |

Additional | sample available, discount will be given by the large order |

FEATURE

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth

- Q: What does plywood mean and its synthesis?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: The difference between the multilayer board and the plywood is as follows

- Commonly used plywood, plywood and other multi-layer board. Multilayer boards can improve wood utilization and are a major way to save wood

- Q: The structure of the plywood at the same time meet two basic principles

- So the plywood is usually three, five, seven odd level layer. The name of each layer of the plywood is: the surface of the board is called the table, the inner plate is called the core board;

- Q: Class I resistant weather plywood Class II water resistant plywood

- Hard fiber board sound absorption, waterproof performance is good, durable, easy constructio

- Q: How to use building plywood?

- Building plywood is mainly used in outdoor conditions, such as building decoration and concrete template

- Q: Plywood is a common material for furniture?

- The usual length and width specifications are: 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on. The main tree species are: camphor, willow, poplar, eucalyptus and so on.

- Q: What plywood is now commonly used?

- According to the different composition of the glue, for the construction of plywood with the following types of glue:

- Q: Material for the plywood defects which

- spotted flecks streaks system wood fungus invasion of wood early formation, often see brown. Tan or purple stains.

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: Why is the plywood commonly used in the singular layer

- This is a good understanding of the regardless of the plywood and plywood they are for the sake of their each of them are vertical lines of the

Send your message to us

Construction Plywood Sheet Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords