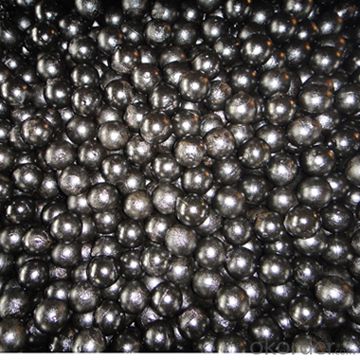

Ball Mill Grinding Media With Chrome Iron Materials From Ningguo,China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Mill Grinding Media-B Technical Specification:

Product Name | Designation In China | C | Si | Mn | Cr | Mo | Cu | Ni | S,P |

| ZQCr 26 | 2.11-3.6 | 0.3 - 1.2 | 0.3 - 1.5 | 23 - 28 | Micro amount

| ≤0.08 | ||

ZQCr 20 | 2.11-3.6 | 0.3 - 1.2 | 0.3 - 1.5 | 19 - 23 | ≤0.08 | ||||

ZQCr 17 | 2.11-3.6 | 0.3 - 1.2 | 0.3 - 1.5 | 16 - 19 | ≤0.08 | ||||

ZQCr 15 | 2.11-3.6 | 0.3 - 1.2 | 0.3 - 1.5 | 13 - 16 | ≤0.08 | ||||

ZQCr 12 | 2.11-3.6 | 0.3 - 1.2 | 0.3 - 1.5 | 11-13 | ≤0.08 | ||||

ZQCr 10 | 2.11-3.6 | 0.3 - 1.2 | 0.3 - 2.0 | 10 - 11 | ≤0.1 | ||||

| (HRC) Surface Hardness | Impact Toughness (AK J/cm2) | Microstructure | Specification(mm) |

| ≥58 | ≥3 | Martensite+ Carbide | Ø10, Ø12.7 ,Ø15,Ø17, Ø20 ,Ø25, Ø 30,Ø 35, Ø40, Ø50, Ø 60,Ø 70, Ø80, Ø90,Ø100, Ø110, Ø120

|

Ball Mill Grinding Cylpebs Chemcial Compostion:

Dimension | C | Si | Mn | Cr | P,S | Cu | Mo | Others |

Φ14*14/16, Φ16*16/18, Φ18*18/20, Φ20*20/25 Φ25*30, Φ30*35, | 2.1-3.2 | 0.3-1.2 | 0.3-1.0 | 10-11 | ≤0.1 | Micro-amount | ||

Microstructure:M+C;≥58HRC

Our Grinding Ball Production Line:

1.Sand Lined Iron Mold Casting Line,which is Applicable For Chromium Grinding Balls With Diameter 40 To 150mm,Average Production Capability 2 Tonne Per Hour Per Set.

2.Flaskless Molding Casting Line:Suitable For Batch Production Of Casting Balls With Diameter 10 To 40mm,Casting Cylpeds Dimension Range From 6*6mm To 40*45mm,And Even Small Castings.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- I am doing this for sale, if the price is mainly based on the product structure, the difficulty of pricing. At present, if it is more formal and material guarantee manufacturers generally in 48-53 yuan /Kg (of course, products have a certain weight, such as greater than 100g), our company's current price of about 53 yuan /Kg or so. .

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: Is the cast steel a casting part?

- Cast steel is divided according to material, as well as cast iron parts, cast aluminum parts and so onCasting parts are divided according to the method, as well as forging partsCast steel parts must be casting parts

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: How to cast iron and wrought iron collocation

- 3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory. 4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is only to do in the factory. About it, may not be full, but through these methods, generally can distinguish between iron or wrought iron.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguish from scopeShanghai Zhejiang forest auto parts experts pointed out that the forging process can eliminate cast loose, metal welding holes, so an important part of high load working conditions, severe machinery, in addition to relatively simple shapes can be rolled plates, profiles or welded parts, the forging process. Because of its low cost and good economy, casting parts processing is widely applied and belongs to the basic process of modern machine building industry.

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- Tangshan Yongding automobile spare parts factory also give a lot of supply, casting factory of Tangshan n to the car enterprises casting wheel gearbox etc.The team of casting experts welcome you to ask questions and accept questions!

- Q: What are the general technical requirements for casting parts?

- According to the national standard GB/T 9438, there are 8 aspects: 1. chemical composition; 2. delivery status; 3. mechanical properties; 4. dimensional tolerances; 5. weight tolerances; 6. appearance quality; 7. internal quality; 8. casting salvage.

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

- Q: Shandong foundry, casting small pieces of precision casting

- Dongying Huayang precision casting factory, the smallest to do 2G pieces.

Send your message to us

Ball Mill Grinding Media With Chrome Iron Materials From Ningguo,China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords