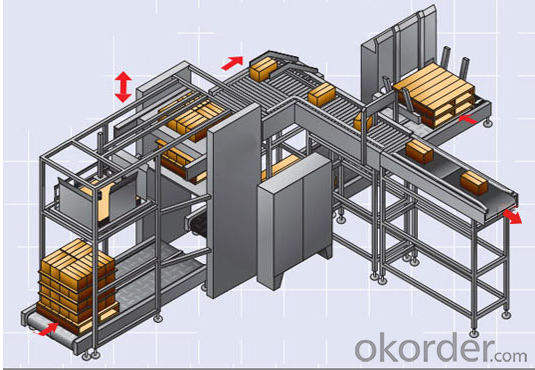

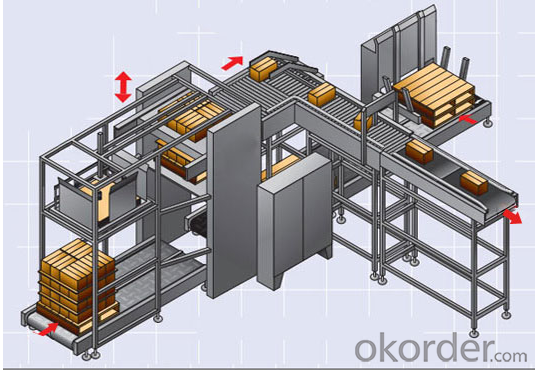

Automatic Depalletizer Machine for Packaging Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Depalletizer Machine for Packaging Industry

1. Product Description:

The depalletizer is new style one which is researched and developed by absorbing advanced technology aboard. It is suitable for different medium and large beer filling production line, some functions will be changed or added according to the customer's actual requirement. The machine features as easy operation, smooth running, large output and easy maintenance.

2. Product Features:

1) This machine is composed of lift, transfer table, can pushing part, roller 1, roller 2 and operation platform.

2) Elevating part

3) Lift is used for lifting pallets to the height of transfer table and pushing cans to the transfer table by can push parts.

4) Transfer table

5) This part is used for can storage and transport.

6) Can pushing parts

7) It is used for pushing cans to transfer table from pallet.

3. Product Parameters:

Capacity | 800cans/min |

Applicable products | CAN,PE,PP,GLASS BOTTLES |

Totaln Power | 7KW |

Total Weight | 5000kg |

Motor Power | 3x380x3PH |

Copressed air supply | 0.8Mpa |

Applicable stac size(standard) | 1400x1100x2300mm(LXWXH) |

Air Supply Consumption | 0.2m3/min |

Can Conveying Mesh Chain | 4000mm |

Out Dimensions(Standard) | 12700x3500x4300(LXWXH) |

Equipment Capabilities: |

CNC Lathes/Lathes/Automatic Lathes/CNC Shearing Machines/CNC Bending Machines/Machining Center/Grinding Machines/Milling Machines/Turning Machines/ Welding Machines/Cutting machines/ Wire-Cuts/ Laser Cuts/Punching Machines/Ditching machines/Polishing machines/Combined Processing Machines and other specialized processing equipments etc. |

Materials Capabilities: | Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. |

Brass: H59/3602/2604/H62/ etc. | |

Copper/Bronze | |

Stainless Steel:201/202/303/304/316/412/ etc. | |

Steel Alloy: Carbon Steel/Die Steel/etc. | |

Other Special Materials: Lucite / Nylon / Bakelite / Plastic/etc. | |

Various kinds of materials can be chosen, we can produce cnc machined aluminum parts according to your requirement. | |

Surface Treatment: |

Anodizing/ Black Oxide/Electroplating/Heat Treating/Brushing/ Grinding/Polishing/painting /Powder Coating/Nickel plating. |

Inspection tooling: |

Outer micrometer, inside micrometer(machine),digimatic micrometer, internal micrometer, mechanical caliper , vernier caliper ,caliper(digital), caliper(machine),caliper(dial),diameter scale, depth micrometer, digital caliper, altitude gauge, electric balance),2D measurement inspection instruments etc |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

5. Product Pictures:

- Q: Where is secondhand corrugated paper packaging machinery available?

- Start a small yellow cardboard box factory, they have the best business, began the purchase of machinery, plant hire.In an unfamiliar field, we should listen to the opinions of experienced people.Carton is a supporting product of consumer products, so to speak, as long as people have consumption, enterprises and products, there will be no lack of product packaging.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you have your own website here, through the optimization and promotion, to promote their products out, the customer concern, love content search, when people search through GG to see your home site, you may consult. There are many ways

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is suggested that displacement or velocity should be detected on the transport path of the membrane. Is a more reliable control signal. Of course, you can also detect the angular speed of the recovery drum, such as a code dial and other simple institutions.

- Q: What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- . This is the importance of after-sales service. Qingdao Xun packaging machine models, can meet the needs of all levels.

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packing machine? Should the packing of the tableware be contracted? Tak Cheung packing machinery, automatic heat shrinkable tableware packing machine can be considered

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

- Q: Energy saving reform of packaging machine

- First, the working principle of food packaging machinePillow type automatic packaging machine of the present domestic leading and most mature and reliable design and production technology, the essence of a collection of many years of experience in the field of packaging machinery, the packing machine can be used in a variety of composite packaging film coil on the packaging of bulk food, very suitable for the majority of users need to Chinese. 1) the electrical parts of the automatic packing machine are usually made up of the following parts:

Send your message to us

Automatic Depalletizer Machine for Packaging Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords