Tin Sheet Cutting Machine Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set carton set

- Supply Capability:

- 1000 Sets per Month day set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

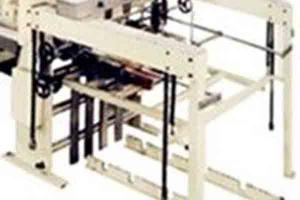

Tin Sheet Cutting Machine Manufacturer

This tin sheet cutting machine is used to cut tinplate ,silicon steel and other metal with high accuracy and high efficiency,

1.Main technical parameter:

Applying range |

Thickness of plate: 0.14-0.5

Width of plate: 40-1050mm |

Production capacity |

1.6metre/second |

Type of Moto | Y90L-6 |

Rotate speed |

940/min |

Power consumption |

1.1kw |

Size |

15oo ×1100 ×1200mm |

weight |

About 1000kgs |

2.Main application:

This Tin sheet cutting machine is applied to cut tinplate ,silicon steel and other metal with high accuracy and high efficiency, it's the necessary equipment in tin can making factory. This machine also include a knife sharpener to sharpen the knife and a handle to adjust cutting size at any time.

- Q: I have an annular core with a stack thickness of 40mm, a high 50mm, an inner diameter of 88mm, and an outer diameter of 168mm. I want to go around a spot welder or an electric welder. How many turns and how many turns are there in the first coil? How to calculate?

- The core section is insufficient, so the power of the welder is not enough,

- Q: Spot welding is not stable, how to adjust?

- The double point welding current welding principle, when the two electrode pressure workpiece makes two layers of metal forming some contact resistance in the two electrode pressure, welding current from the electrode through another electrode is formed on the two point contact resistance moment of welding, and the welding current from another the two part flow along the electrode with the electrode to form a loop, and is the internal structure of welders.

- Q: What should be done with welding and welding of suspension type spot welding machine?

- The welding current can be adjusted properly and the welding time will be reduced. Your plate feels a little thin, so think of setting it up. It is not possible to consider the gold chelate spot welding machine, DC welding, very small splash, the sheet is not splashing, it is good for people's health. Hope to help you. Baidu can call me in Chengdu or the Southwest

- Q: What copper is used for the tools used in spot welding machines?

- Tungsten bronze should be used.

- Q: I have a transformer capable of entering 220V 6V 12V 24V 36V capacity 1000VA low rated current 27A, I want to make it a touch welder. Do 2 square meters of small wire connector. Need to add something, want to play a few, to the points

- The core side area is 35 square centimeters to 40 square centimeters, iron core 40 square centimeter more than 1000WElectric welding machine can do, so big iron core can do a not very small electric welding machine.Solution: if you are a 220V input voltage, copper wire diameter of 1.8 mm to 2.2 AWG, per volt 1.2 bar. The normal is 220 volt *1.2 =265 tie bar. (my personal experience is that you take 255 taps, 275 taps, and one spare. After the current is big, use 275Secondary flat copper wire can be 12 to 16 square meters. 42 sticks, one tap, 48 sticks, one tap, 54 sticks one. It is the big and small gear of the electric welding machine. 13 or 14 square lines are recommended.Such an electric welder, you do what touch welding can be, very good use.

- Q: I used the Zhenjiang Seiko welding

- It is possible that the current is too small, or that there is a foreign object in the metal contact surface or that the contact surface is uneven. It is possible that the power of the spot welder is not enough.

- Q: Spot welder can weld several points at the same time

- Multi spot welder is usually a transformer double winding, one side double points can be welded 4 points, redistribution is another.

- Q: Customers who need batteries and series automatic spot welders can contact Dongguan three edge automation

- Spot welding power supply can be used as "characteristic welder" to recognize the sign "Styler". This is authentic.

- Q: You ask the master, a suspension spot welding machine control principle, I now need to do a detection tool for specific details: when the success of welding torch ends will have powerful currents, I mainly when this powerful current I will remember a welding work data, this is my signal how should the acquisition. Or how should I find the signal point in the control cabinet of the electric welding machine? I have the circuit diagram of the welder here, because the first contact with the welding machine is not very clear. I am a novice, look Haihan heroes!

- You this is the equivalent of a counter current through the method, considered a record, but the conventional signal acquisition counter voltage value, you can pass the current into voltage does not exceed the value of 30V to counter acquisition equipment above, when the voltage reaches above 5V can be considered to be a high level, a number of the best. You calculate this current size range, across an appropriate resistance, by recording more than 5V times more than by the voltage of this resistance to count.

- Q: What is the price of a general suspension type spot welder?

- Suspension spot welding machine in the general price of about 20 thousand, is the main cable holder, the choice of different position, different electrode holder, sometimes the difference between the more special.

1. Manufacturer Overview

| Location | Jiangxi,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | Below US$1 Million |

| Main Markets | South America 1.04 Southeast Asia 3.26 Africa 7.92 Mid East 8.81 Eastern Asia 0.54 South Asia 2.25 Domestic Market 76.18 |

| Company Certifications | Consumer Trustworthy Company;Member of Chiese packaging technology association;Trust-worthy Company |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Average |

Send your message to us

Tin Sheet Cutting Machine Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set carton set

- Supply Capability:

- 1000 Sets per Month day set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords