Auto Parts Brake Shoe & Components (OEM/REM) Non-asbestos Heavy Duty Truck Brake Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Auto Parts Brake Shoe & Components

We are a partner truck brake lining ,brake pad for truck/bus .

Main Features Of Auto Parts Brake Shoe & Components

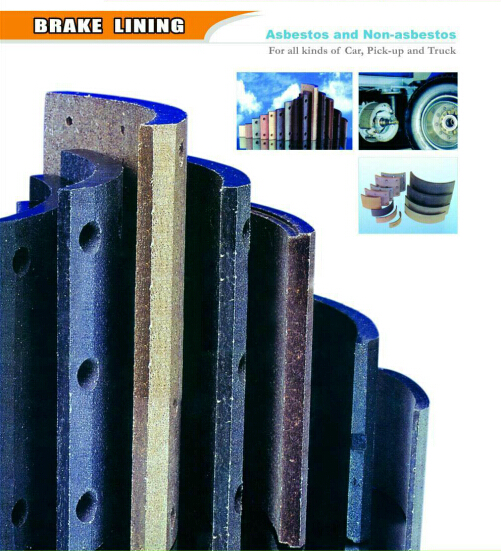

Brake lining Features: (non asbestos brake lining)

1, Formula: asbestos brake lining and non-asbestos brake lining

2, Low Noise, excellent friction characteristics and , long-term service life;

3, Processing Methods: Prepare Prescription, Hot-press, Heat-treatment, Drill, Grind, Dust-clear;Packing.

4, Useful life : normally 12months or 20000km .

Specifications of Auto Parts Brake Shoe & Components

truck brake lining, auto brake pad

SABS (South Africa ) , SAE J2115 , SAE J661 /CHASE, ISO16949

12 MONTHS OR 20000KM LIFE

| Type: | brake lining | Material: | non-asbestos | Certification: | SABS (South Africa ) , SAE J2115 , SAE J661 /CHASE, ISO16949 |

| Size: | 205*18.0/11.0*180 | Car Make: | SAF,BPW,MOL,SAE,Cardi etc | OE NO.: | 19032 |

| Place of Origin: | Zhejiang China (Mainland) | Brand Name: | JUTIN BRAKE LINING | Model Number: | TRUCK BRAKE LINING 19032 |

| BRAKE LINING CERTIFICATE: | SABS (South Africa ) , SAE J2115 , SAE J661 /CHASE, ISO16949 | NORMAL USEFUL LIFE: | 12 MONTHS OR 20000KM | TRUCK BRAKE LINING COLOR: | BLACK , SHINE , BLUE , YELLOW , RED |

| SAMPLE: | FREE |

Packaging & Delivery

| Packaging Detail: | BRAKE LINING PACKED BY: EACH SET USED SHRINK COVERING IN CARTON BOX |

| Delivery Detail: | BRAKE LINING CAN BE SHIPPED 15 TO 45 DAYS |

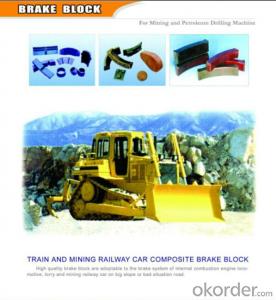

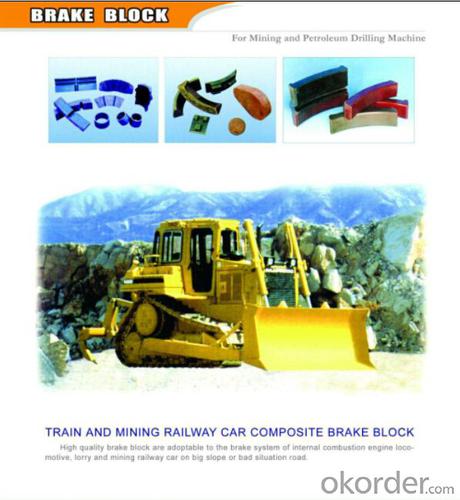

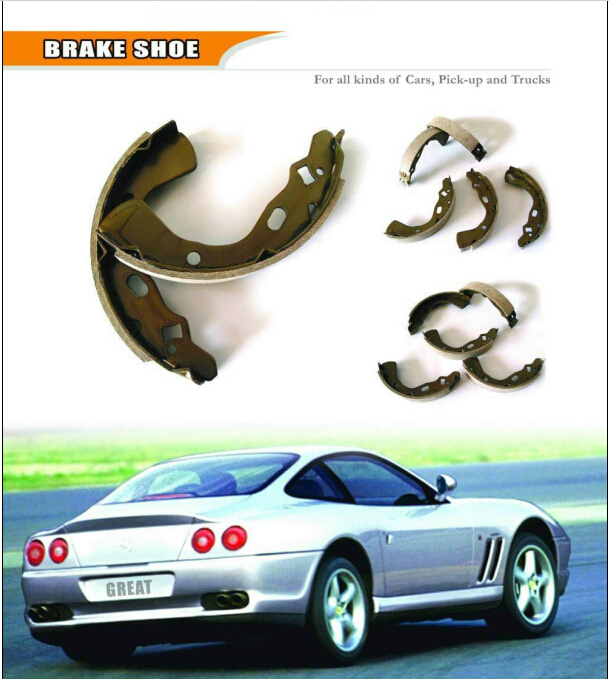

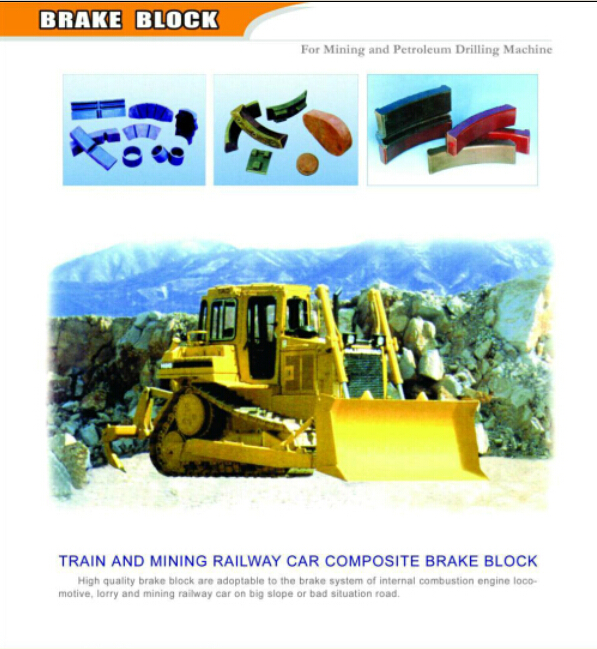

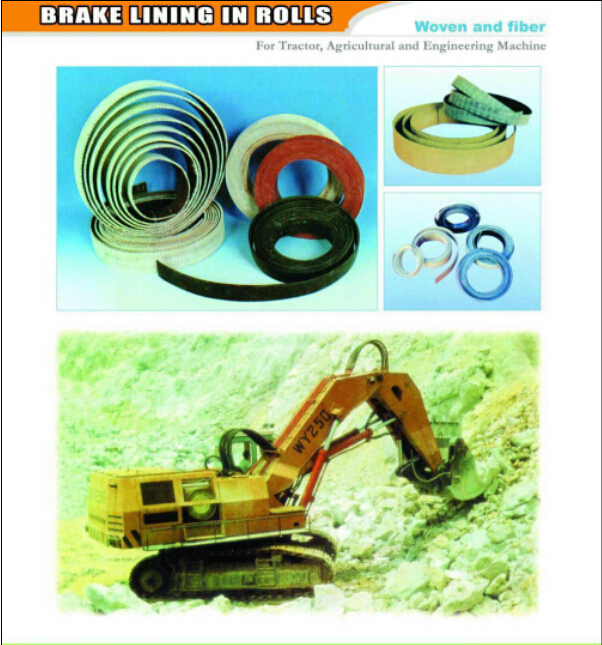

Auto Parts Brake Shoe & Components Images

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Do I need flanges for rubber joints?

- In this case, 4 flanges are required for a productGongyi Kin Kun water supply equipment factory produces rubber soft joints all year round

- Q: What do butt welding flanges WN300-150, RF, Sch40 mean?

- WN said neck flange; 300 said flange nominal diameter DN300 welding diameter of 325MM, the 150 refers to the nominal pressure flange is 150LB (pounds) system will usually only America in pounds nominal pressure; RF said flange sealing surface for ordinary raised face seal, SCH40 said steel tube wall thickness, the thickness is 10.31MM general welding neck flange with ring loose flange complete specifications are required to fill in the pipe wall thickness.

- Q: What are the common materials and grades of aluminum alloy flanges?

- The aluminum alloy flange is a connecting part between the pipe and the pipe, used for the connection between the ends of the pipe. It is also used in the flange of the equipment entrance and exit. It is used for the connection between the two equipments, such as the reducer flange. Flange connection or flange joint means that the flange, the shim and the bolt are mutually connected as a group of three detachable sealing structures.

- Q: The connection between the air outlet and the air duct can straddle the flange

- Can not.The air outlet must be connected directly to the air duct. If the size of the air outlet is larger than the length of the air duct, a suitable length of air duct must be made to facilitate the connection of the air inlet.

- Q: What is the maximum pressure of the flanges RF and RTJ?

- The use of with concave convex surface with tongue and groove face flange is basically the same. Ring groove sealing surface (RTJ) is mainly used in high temperature and high pressure or both high working conditions. In American Standard flange, commonly used in Class 600Lb (part) and 900Lb, 1500Lb, 2500Lb grade pressure. In the German standard and national standard, often used in PNl0.0, PN16.0, PN25.0, PN32.0, PN42.0MPa flanges.

- Q: The soul of darkness, how about the souls on the slopes beside the cursed frogs outside 3 flanges?

- Extinguish the flames of the 3 towers; open the doors; there is a way to go there

- Q: Our factory production of wind tower is to use forged flange (and specification is written in the continuous casting slab is not allowed), incoming raw materials warranty flange is written in continuous delivery, that is not the flange casting forging? Are you in a hurry to accept the goods?! I have less money, thanks in spirit, please knowledgeable people teach in, with little to say, it is best to have some basis for what? Thanks a million!

- Forged flanges and cast flanges use different levels of stress, and forged flanges can be used in high and low pressure pipelines,Casting flanges can only be used for non pressure lines, otherwise leakage is very easy.Hebei bend flange, my name is Liu Jiangong.Flange production using continuous casting does not mean that the flange is casting, can only say that raw materials are not up to standard. Let's pay for the goods. High pressure pipe, as far as possible the use of round steel material.

- Q: Optical fiber telecommunications, but there is no place I want to position myself to buy white pigtail jumper modification to the living room TV wall. Now my idea is in the middle of the 2 flange butt joint SC, SC head of a white line connecting leader Telecom, a leader to the wall plug SC flange joint, I said because the total length of 50 meters and it would be enduring great??? The speed of the impact is not big?!!!! StopThe multimedia box SC box - Telecom - strong SC flange flange ----SC pigtailed light cat2 flanges! Wait for God online!!!!

- Of course, also need to use some domestic good quality goods, Jingdong search ranking in front of a few can, like win for brand is good

- Q: What are the specifications of orifice flanges? Be comprehensive

- Appendix A of national standard HG 20592-2009 is marked with only WN (high neck welding flange)Pressure rating PN10~PN160Beside the flow hole socket welding or NPT mouth NPS 15 bearingASME B16.36-2009 American Standard marked WN (high neck flange) and SO (neck flange) twoPressure level 300LB~2500LB no 150LBBeside the flow hole for the 1/2 "NPT age

- Q: What does the flange 20592-MFM stand for?

- MFM refers to the upper and lower flange of the matching structure of the sealing surface, is the concave convex surface of the matching: M is convex, FM is concave.

Send your message to us

Auto Parts Brake Shoe & Components (OEM/REM) Non-asbestos Heavy Duty Truck Brake Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords