Auto-Climbing Formwork CONSTRUCTION FORMWORK SYSTEMS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

System Introduction:

Auto-climbing Formwork System uses the hydraulic system as power, it includes the oil cylinder and two commutators. The commutators can control the climbing of climbing rail and the bracket. The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily, it does not need the cranes.

Characters:

1. It could climb vertically or slantwise.

2. It could climb integrally or separately, the climbing process is steady, synchronous and safe.

3. The formwork will not dismantle to the ground until the construction finished. The field will be saved and the impacting breakage will be greatly reduced (especially the plywood).

4. The system will furnish all-round platforms, and additional platform is not needed.

5. The formwork can climb itself and cleaning work can be done in situ. The use of tower crane will be greatly reduced.

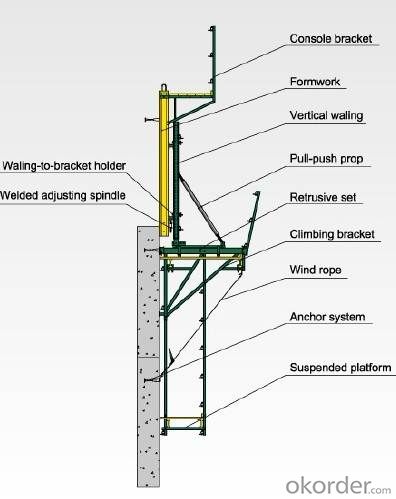

1. Structure of Cantilever Formwork Description

Cantilever Formwork is mainly used in the concrete pouring of pier, high buildings, and so on. The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical. A single pouring height is high and the finished concrete surface is perfect. Cantilever formwork has several types, the structure is similar, and has its own different characteristic. Can use them according to actual demand.

Main cantilever Formwork:PJ200 & PJ240,CB-240 etc.

2. Main Features of Cantilever Formwork

-easy to assemble

-simple structure.

-easy, rapid and economical.

3. Cantilever Formwork Images

4. Cantilever Formwork Specifications

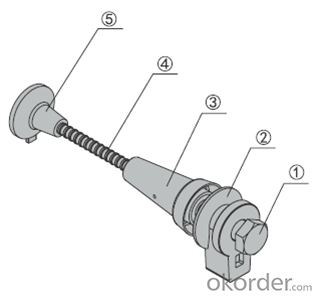

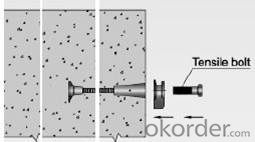

Anchor system

Anchor system is the most important supporting part. The system is made of five parts shown below. There into, tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusing after the concrete pouring.

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

5.FAQ of Cantilever Formwork

1) What can we do for you?

.We can ensure the quality of the Cantilever Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Where was the construction machinery conference held in 2015?

- Organizer: China Academy of machinery science and engineering machinery and military modified vehicle testing center, Shandong Bada International Engineering Machinery Company Limited, Shandong Bada Luqiao Construction Co. Ltd. and Shandong northern Luqiao Engineering Company Limited. Organizer: Shandong Bada international engineering machinery City, Lee brothers auction, Beijing Shengda Trade Center, Hing Beijing power machinery and equipment in the international science and Technology Co Ltd

- Q: Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Product quality certification, also known as product certification, internationally known as qualified certification. According to the 1991 implementation of the "people's Republic of China Quality Certification Management Regulations", the product quality certification is based on the product standard and relevant technical requirements, the certification institution confirmed by the certification and certification marks to prove that a particular product is in conformity with the relevant standards and technical requirements of the corresponding activities.

- Q: How are the machine parts stacked?

- Classification ah! Put small pieces of different sizes and functions into boxes and attach labels; larger items can be placed outside in a certain order (for example, function, length, value, etc.)

- Q: Definition of large mechanical equipment?

- The hoisting machinery used in bridge construction can be divided into three categories: light and small lifting equipment, bridge type crane and boom type crane. Light and small lifting equipment, such as jacks, hoists, winches, etc.. Bridge type lifting machinery, such as beam cranes, Longmen cranes and so on. Boom type cranes, such as stationary slewing cranes, tower cranes, truck cranes, tires, crawler cranes, etc..

- Q: How do the welding parts in the welding drawings of the machine parts indicate the technical requirements of the drawings?

- Therefore, the medium carbon steel has the most extensive application in the medium strength level. Besides being used as building material, it is widely used in the manufacture of various mechanical parts. Welding: 1 the preheating is conducive to reducing carbon steel heat affected zone is the most

- Q: What are the world famous mechanical equipment exhibition?

- 3, the French international civil engineering and Construction Machinery Exhibition (INTERMAT) the European Construction Committee (CECE), founded in 1988, tenth in 2015, is one of the three famous exhibition of world engineering machinery and construction machinery field, three years. France INTERMAT exhibition exhibits covering mining machinery, earthmoving machinery, concrete machinery, lifting machinery, pavement and compaction machinery, piling machinery, industrial vehicles, pneumatic tools, drilling machinery, building materials machinery, mining machinery and other engineering and construction machinery and spare parts industry. Paris International Construction Machinery Exhibition in Europe - the Middle East - Africa (EMEA) region has a unique position.

- Q: China mechanical net

- From Chinese GM parts, general machinery, hardware, tools, instruments, electrical appliances and related equipment, textile equipment, chemical equipment, agriculture, food equipment, construction equipment, environmental protection equipment, mining equipment, metallurgical equipment, financial equipment, commercial vehicles and accessories, machinery processing equipment, machinery processing industry machinery enterprises and mechanical products

- Q: How are buildings, installations and materials divided?

- Equipment generally includes the following: (1) all kinds of equipment and the equipment with the arrival of accessories, spare parts and equipment attached to the body made of ladders, platforms, railings and pipes. (2) various gauges, instruments and automatic control devices, experimental instruments, instruments and meters in the main part of the equipment. (3) components of equipment, such as oils, chemicals, etc. attached to the equipment body.

- Q: What is a door rack for a construction site? How high is it generally?

- Construction machinery network learned that the door scaffolding in our country production and use of time is not long, the scaffolding developed by the various research institutions, self-contained, and not common, varieties, specifications and diverse. Some factories copy foreign products and use the imperial size.

- Q: What functions should be achieved in mechanical structure design?

- The function of the mechanical structure is mainly realized by the geometry of the machine parts and the relative position between the parts. The geometry of a part is made up of its surface, and a part usually has a number of surfaces, some of which are in direct contact with the surface of other parts, and this part of the surface is referred to as the functional surface. The connecting part between the functional surfaces is called the join surface

Send your message to us

Auto-Climbing Formwork CONSTRUCTION FORMWORK SYSTEMS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords