Auto-Climbing Formwork of CONSTRUCTION FORMWORK SYSTEMS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

climbing formwork

1.Material: ASTM45#,Q235 steel

2.ISO 9001:2008

1. Specifications:

| Commodity | climbing formwork |

| Specifications | 45# steel or Q235 |

| Colour | primary |

| Length | according to customers' requirement |

| Usage | building construction |

| Technical processing | hot rolled |

| Surface | F Type Flattening |

| Packing | 200pcs or 400pcs in a pallet |

| in a container | |

| MOQ | 20 metric ton |

The concrete form panels are kind of systemized formwork, easy to install and to dismantle for the reinforced concrete construction in any type. The structure of the panels is conveniently designed for various functions, enabling the panels to be reused repeatedly, helping save the costs on materials and reduce the times for work by simplifying and accelerating the process. Consequently it can cut down on the labor costs and expenses. Basic and standard products as well as various products for different types and sizes of constructions are available from manufacturing. Recycling the panel after its life-span can help reduce costs, because we can remove plywood, adjust the frame and the angle, get rid of the impurities, carry out coloring and finally attach the new plywood. The recycled forms still perform as good as the new ones, with substantially reduced costs. Other types of recycled panel are those who combine the recycled frames and the used plywood which is still in good condition.

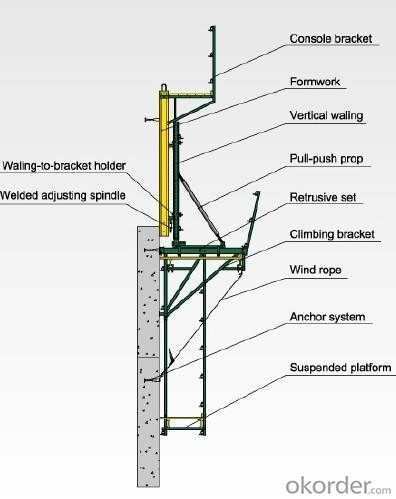

1. Structure of Cantilever Formwork Description

Cantilever Formwork is mainly used in the concrete pouring of pier, high buildings, and so on. The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical. A single pouring height is high and the finished concrete surface is perfect. Cantilever formwork has several types, the structure is similar, and has its own different characteristic. Can use them according to actual demand.

Main cantilever Formwork:PJ200 & PJ240,CB-240 etc.

2. Main Features of Cantilever Formwork

-easy to assemble

-simple structure.

-easy, rapid and economical.

3. Cantilever Formwork Images

4. Cantilever Formwork Specifications

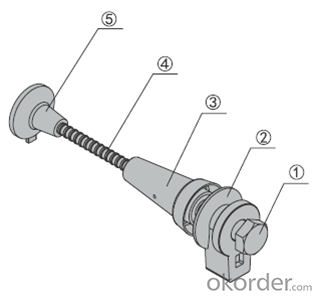

Anchor system

Anchor system is the most important supporting part. The system is made of five parts shown below. There into, tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusing after the concrete pouring.

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

5.FAQ of Cantilever Formwork

1) What can we do for you?

.We can ensure the quality of the Cantilever Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q: Where was the construction machinery conference held in 2015?

- Co organizer: BMW (Chinese) Engineering Machinery Company Limited, Shandong Lingong Construction Machinery Co, Limited by Share Ltd, Shantui construction machinery Futian leiwo international heavy industry Limited by Share Ltd, Shandong Chang Linzhu Machinery Group Limited by Share Ltd, Shandong rhinos Engineering Machinery Company Limited, Beijing Tianshun Hydraulic Technology Co., Ltd. Ji'nan the Great Wall Andy Machinery Co. Ltd., Langfang Deji machinery Polytron Technologies Inc, Tai'an Dongyue Heavy Industry Co. Ltd.

- Q: What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ fail safe design: in the part of the system, equipment malfunction or damage, can also ensure the safety of safety and technical measures known as fault - Safety Design in a certain period of time (fail-safe). Generally speaking, through careful technical design, the system and equipment are in a low energy state when the fault occurs, thus preventing the unexpected release of energy. For example, a fuse in an electrical system is a typical fault - Safety Design; when the system is overloaded, the fuse is fused and the circuit is disconnected to ensure safety. Although the fail safe design is an effective measure of safe technology, but considering the fail safe design itself may not work due to failure, so the choice of safety technical measures should not give priority to the use of.

- Q: What kind of electrical equipment do you have? What are the main components of each device?

- Electrical equipment, electrical parts, electrical equipment, electrical components: mainly refers to other construction equipment matching, power driven, electrical heating, electrical lighting, and other direct consumption of electricity and into other parts of energy. Such as: motor and electric heater and start control equipment, decorative lighting lamps and the switch socket, television communication and intelligent engineering for power supply and transformation or environmental protection dust and kitchen fume and other special DC power supply etc.

- Q: What type of industry does the machinery and building accessories processing belong to?

- There are only three tax categories in our country: 1 consumption tax, 2 VAT, 3 special tax (agriculture). Therefore, as long as the manufacturing or processing of industrial value added tax on enterprises. It has nothing to do with the economic nature, classification and categories of an enterprise.

- Q: What are the safety protection equipment, machinery and equipment, construction machinery and accessories for construction enterprises?

- For Turner, fitter, main work gloves, hats, goggles for welder, etc.; there are gloves, shoes cover, goggles, insulated shoes etc.;...... ;

- Q: Where are the mechanical pressurization air supply facilities set up?

- The purpose of setting up a mechanical pressurization air supply smoke prevention system is to provide evacuation routes and shelters without smoke interference in the event of a fire in the building. Therefore, in the closed door, pressing position, and the fire floor must maintain a certain pressure difference, the position of the air pressure value is a relative positive pressure); at the same time, in the open part of the pressure when the door can have enough air velocity in the opening section, to effectively prevent the intrusion of flue gas, the safety of personnel ensure evacuation and refuge.

- Q: What are the world famous mechanical equipment exhibition?

- 1, the German BMW Exhibition (BAUMA) sponsored by: Messe M nchen GmbH, held every three years, has held 30 sessions, the thirty-first will be in April 2016 11-17 in the German city of Munich exhibition centre. The German international engineering machinery, building materials machinery, mining machinery, construction vehicles and Equipment Expo is the world's largest and most influential international engineering machinery, building materials machinery, mining machinery industry exhibition, every three years regularly held in Munich in germany. The fair combines science and technology, trade, information and technical cooperation

- Q: What is a door rack for a construction site? How high is it generally?

- This depends on the erection of the height of the general 3 steps and within 5-6 yuan a meter, assuming the erection of 4.5 meters high, 22.5-27 yuan a square. This is calculated in accordance with single-layer, the higher the more expensive, 9 meters in 65 yuan or so square. In accordance with the establishment of meters, in accordance with the erection of the volume of the calculation.

- Q: What are the sub projects of a construction project?

- Appendix B Construction Engineering Division (sub branch) engineering, sub project division, B.0.1 Construction Engineering Division (sub branch), engineering, sub projects can be divided into table B.0.1. Table B.0.1 division number of construction works, sub works and sub projects

Send your message to us

Auto-Climbing Formwork of CONSTRUCTION FORMWORK SYSTEMS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords