Auto-climbing Bracket ACB50 formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

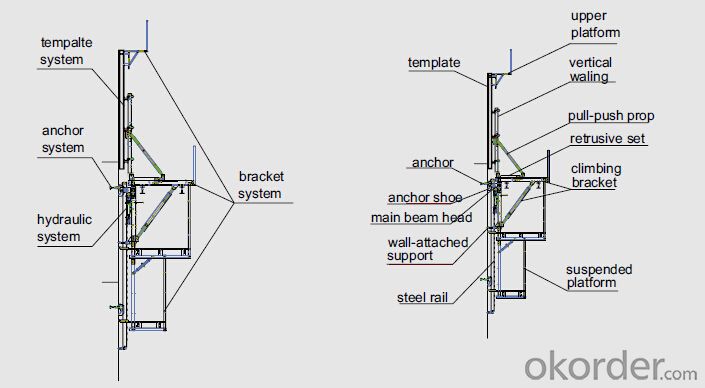

Auto-climbing Bracket ACB100 & ACB50

The power of the auto-climbing formwork is the hydraulic system, which includes the oil cylinder

and two commutators. The commutators can control the climbing of climbing rail and the bracket.

The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily.

Cranes are not needed during the construction. It’s easy to operate, highly efficient and safe. It’s

the best choice for the construction of high buildings and bridges.

There are mainly two types of standard auto-climbing brackets, ACB-50 and ACB-100, the figure

means the push power of cylinder with unit of KN.

Characteristics:

◆ Perfect load bearing anchor system

Anchor system is the most important supporting part. The system is made of five parts shown

below. Thereinto, tensile bolt, V-climbing cone and washer can be taken out for reusing after the

concrete pouring finished.There are two kinds of anchor systems,A & B. A is matched with single

anchor shoe and B is matched with double anchor shoe.

◆ Crane-independent

Crane-independent forming, striking and climbing speeds up the work procedures on the

construction site and also makes them independent of each other. This means the planned

sequences can be maintained along with guaranteeing high productivity levels. The crane can

therefore be used for other tasks.

Hydraulic system is mainly made of two commutators,

oil cylinder and power distribution system.The

commutators can control the climbing of climbing rail

and bracket.

◆ High bearing capacity and safe

The stable working platforms are able to carry large loads, e.g. the storage of reinforcing steel

for the next climbing section. Generously-sized working platforms, the well thought-out design for

handling very high wind loads and the patented control function of the climbing mechanism are

some of the special details contained within the comprehensive safety concept.

◆ Platforms adjusted to suit the angle of inclination

The horizontal working areas thus created provide safe and comfortable conditions for

reinforcement work, shuttering and striking, concreting and finishing.

◆ The ACB formwork system can climb not only vertically but also slantways, the largest angle is

18 degrees.

◆ The system can climb up wholly or separately. The climbing process is steady, synchronous

and safe.

◆ The bracket will not fall to the ground until the construction is finished, the field will be saved

and the impacting breakage will be reduced (especially the panel).

◆ The system will furnish omnidirectional platform, the construction organizations don’t need to

set up additional operation platform.

◆ The error of structure construction is small and easy to correct.

◆ The climbing speed is fast, the construction course will be quickened.

◆ The formwork can climb itself and cleaning work can be done in the same situs , the used times

of tower crane will be greatly reduced.

- Q: BMW 3 Series driver seat waist support how much money

- You can consult the local dealer, or repair shop area different prices are not the same, Taobao can also see, I wish you a happy car, safe and secure

- Q: What does the car support for the waist?

- For the waist is not good or long-distance driving lead to the waist fatigue of the crowd, choose a comfortable waist strap height can ease the long driving caused by the waist fatigue, get more comfort.

- Q: Scaffolding brace has several models, respectively, can bear the load?

- They are a lot of good quality models of course, bear the strength of the larger

- Q: What is the range of adjustment for the full range of scaffolding?

- From the safety considerations, the adjustment range of the top care is about 45% of the total support, can not exceed 50%, otherwise it will cause instability.

- Q: Car plus a tire pressure detection and waist support adjustment about how much money

- Hello, tire pressure detection is generally about 200 yuan, waist support you need to estimate about 800 or so, depending on the specific market conditions, and hope to help you

- Q: As the gym did not squat rack, with Smith machine waist twist discomfort, so use the reclining push the practice of squatting, from 40 kg to the current 85 kg. Can this continue to practice it?

- I have seen someone so practice, but with you is the opposite direction, looking at not feel ye, you can talk with the gym, sometimes effective

- Q: Support on why there is adjustable support and support the set position, that is, where to put any place can not put?

- JGJ 162-2008, Fasteners for fastener steel scaffolding "JGJ130-2011 has been clearly defined in the template support pole must be set U-type top care. As long as it is to support the pole will put, and adjustable section may not be greater than 200mm.

- Q: Why 2013 BMW 320LI no waist support regulation, and now 2014 models are still not, as a luxury brand is difficult to understand

- Because it is low-end BMW models, like the 7 series of these have

- Q: Yee Jun Edition Octavia with waist support adjustment?

- Yes, twist for a long time, the waist did not feel the support of the changes, waist down to turn, not sour, it is estimated that the legendary manual adjustment it,

- Q: Is the car seat with lumbar support adjustable?

- It is better to find a mat what to deal with the first look, and slowly find the factory and this opportunity to change it. Also not for this function to give up the favorite models!

Send your message to us

Auto-climbing Bracket ACB50 formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches