Australia Post Packaging Tape - PVC Electrical Tape of 130 Micron Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape of 130 Micron Thickness

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape of 130 Micron Thickness

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape of 130 Micron Thickness

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape of 130 Micron Thickness

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

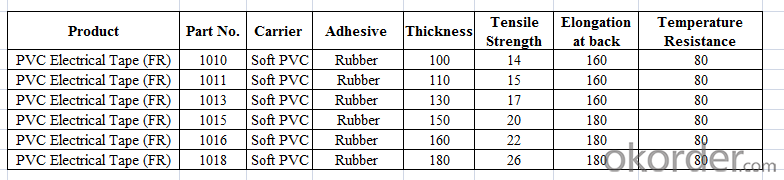

Technical Data of PVC Electrical Tape of 130 Micron Thickness

Product Show of PVC Electrical Tape of 130 Micron Thickness

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Is packaging tape suitable for sealing heavy boxes?

- Yes, packaging tape is suitable for sealing heavy boxes. Packaging tape is designed to provide a strong and secure seal for boxes of various sizes and weights. It is made from durable materials such as polypropylene or reinforced paper, which adds strength to the tape and ensures that it can handle the weight and pressure of heavy boxes. Additionally, packaging tape usually has a strong adhesive that bonds well with cardboard surfaces, ensuring a tight seal that can withstand the rigors of transportation and handling. However, it is recommended to use multiple strips of tape to reinforce the seal on heavy boxes for added security.

- Q: Can packaging tape be used for sealing plastic document holders?

- Indeed, plastic document holders can be sealed using packaging tape. Designed to produce a robust and dependable seal on diverse surfaces, packaging tape is well-suited for use on plastic materials. By securely fastening the tape, the plastic document holder can effectively prevent any papers or items from slipping out. It is crucial, though, to apply the tape uniformly and firmly to guarantee a reliable seal. Moreover, opting for transparent packaging tape is advised to avoid hindering visibility of the documents enclosed within the holder.

- Q: Is packaging tape safe for use on photos or artwork?

- Yes, packaging tape is safe for use on photos or artwork as long as it is acid-free and archival quality tape. This type of tape will not harm or damage the photos or artwork over time.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. It is designed to adhere to various surfaces, including painted surfaces, without causing damage or leaving residue when properly applied and removed. However, it is always recommended to test a small, inconspicuous area first to ensure compatibility and to handle the tape with care to avoid any potential paint or finish peeling.

- Q: Can packaging tape be used for sealing plastic storage bins?

- Yes, packaging tape can be used for sealing plastic storage bins. Packaging tape is designed to be strong and adhesive, making it suitable for securing and sealing various materials, including plastic bins. It provides a reliable and durable seal that helps to keep the contents of the bins secure and protected. However, it is important to ensure that the tape is applied properly and firmly to ensure a tight seal. Additionally, it is recommended to use a high-quality packaging tape that is suitable for the intended purpose to ensure optimal sealing results.

- Q: What are the considerations for using packaging tape on textured surfaces?

- When using packaging tape on textured surfaces, there are a few considerations to keep in mind. Firstly, the texture of the surface can affect the adhesion of the tape. Textured surfaces typically have uneven or rough areas, which may make it difficult for the tape to adhere securely. It is important to choose a packaging tape that is specifically designed for textured surfaces. These tapes usually have a stronger adhesive that can better stick to uneven surfaces, ensuring that the tape will stay in place. Another consideration is the durability of the tape. Textured surfaces can be more abrasive than smooth surfaces, which can cause the tape to wear out more quickly. It is important to select a packaging tape that is made from a durable material, such as reinforced or heavy-duty tape. These types of tape are designed to withstand more wear and tear, providing a longer-lasting bond on textured surfaces. Additionally, the texture of the surface can also affect the appearance of the tape. Since textured surfaces are not smooth, the tape may not lay flat and can create air pockets or wrinkles. This can make the package look untidy or unprofessional. To improve the appearance, it may be necessary to use extra tape or apply it in a way that smooths out any unevenness. Lastly, it is important to consider the removal of the tape from textured surfaces. Textured surfaces can make it more difficult to remove the tape cleanly without leaving behind any residue. To prevent damage to the surface or any sticky residue, it is recommended to test the tape on a small, inconspicuous area before fully applying it. If the tape does leave residue, there are adhesive removers available that can help safely remove any remaining residue. In summary, when using packaging tape on textured surfaces, it is important to choose a tape specifically designed for uneven surfaces, select a durable tape that can withstand the texture, consider the appearance of the tape on the textured surface, and be cautious of any potential residue left behind when removing the tape.

- Q: What are the benefits of using tear-resistant packaging tape?

- Using tear-resistant packaging tape comes with various advantages. To begin with, the use of tear-resistant packaging tape provides added security and protection for your packages during transit or storage. The tape's strong adhesive and tear-resistant material guarantee its integrity, preventing any tampering or accidental tearing of the packaging. This helps to maintain the contents' integrity and minimizes the risk of damage or loss. Furthermore, tear-resistant packaging tape offers greater durability and longevity compared to regular packaging tapes. Its sturdy design and resistance to tearing make it perfect for packaging heavy items, those with sharp edges, or those susceptible to rough handling. This ensures that the tape remains intact throughout the entire shipping process, reducing the need for re-taping or potential damage to the package. In addition, tear-resistant packaging tape often possesses weather-resistant properties, enabling it to withstand various environmental conditions. It is designed to resist moisture, extreme temperatures, and UV exposure, making it suitable for long-distance shipping or storage in different climates. This prevents the tape from deteriorating or weakening, ensuring that your packages remain securely sealed and protected. Moreover, tear-resistant packaging tape is user-friendly and provides a professional finishing touch to your packages. Its strong adhesive allows for quick and secure bonding to different surfaces such as cardboard, plastic, or metal. This ensures that the tape stays in place and does not unravel or loosen during transit. Additionally, tear-resistant packaging tape is available in a range of sizes and colors, allowing you to personalize your packaging and create an aesthetically pleasing presentation for your customers. To summarize, the advantages of using tear-resistant packaging tape include enhanced security, increased durability, weather resistance, ease of use, and a professional appearance. By investing in tear-resistant packaging tape, you can ensure that your packages are well-protected, reduce the risk of damage or tampering, and enhance the overall shipping experience for both you and your customers.

- Q: What is the difference between acrylic and hot melt packaging tape?

- Sealing boxes and packages commonly involve the use of acrylic and hot melt packaging tapes, but they differ significantly in their adhesive properties and performance. Acrylic packaging tape boasts clarity and transparency, making it perfect for situations where package appearance matters. It also resists yellowing and aging, ensuring that it remains clear and does not become brittle over time. With a strong initial tack, acrylic tape adheres quickly to surfaces upon application. However, it may not perform as well in extreme temperatures, as its adhesive strength can diminish when exposed to high heat or cold conditions. In contrast, hot melt packaging tape consists of a synthetic rubber adhesive that is applied as a hot liquid. This tape offers superior adhesion and bond strength, making it suitable for heavy-duty or challenging packaging tasks. It excels in temperature resistance, maintaining its adhesive properties even in extreme conditions. Additionally, hot melt tape is known for its quick and effortless release, making it convenient for high-volume packaging operations. In conclusion, acrylic and hot melt packaging tapes are both effective for sealing boxes, but they have distinct advantages and disadvantages. Acrylic tape is ideal for situations prioritizing clarity, aging resistance, and initial tack. On the other hand, hot melt tape excels in adhesion strength, temperature resistance, and ease of use. Ultimately, the choice between the two depends on the specific requirements and conditions of the packaging task at hand.

- Q: Can packaging tape be used for sealing sports equipment or gear?

- Yes, packaging tape can be used for sealing sports equipment or gear. Packaging tape is designed to have strong adhesive properties, making it ideal for securing and sealing various items, including sports equipment. It can help keep equipment and gear securely fastened, preventing them from coming apart or getting damaged during transportation or storage. However, it's important to consider the specific needs and requirements of the sports equipment or gear being sealed, as some items may require more specialized tapes or sealing methods for optimal protection.

- Q: Can packaging tape be used for sealing wooden crates or pallets?

- Certainly, packaging tape is a reliable option for sealing wooden crates or pallets. Its design aims to create a strong and secure bond, making it suitable for sealing different materials, such as wood. By virtue of its adhesive properties, it adheres well to both the surface of the wooden crates or pallets and the packaging materials used to enclose them, thus ensuring a dependable seal. Moreover, packaging tape usually boasts durability and moisture resistance, safeguarding the contents of the wooden crates or pallets during transportation or storage.

Send your message to us

Australia Post Packaging Tape - PVC Electrical Tape of 130 Micron Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords