1050 Aluminum Coil Price ASTM Grade 1060 Aluminum Belt for Solar Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

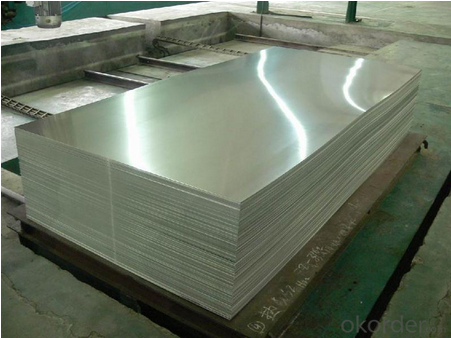

ASTM Grade 1060 Aluminum Belt For Solar sheet

aluminum coil specifications:

1) Alloy :1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 6mm

4) Width:20mm to 3300mm

5)Coil weight: 100kgs to 6 tons depends on actual requirement

6)Core material: Aluminum or paper

7)Coil Inner diameter: 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required

8) Protective film can be added

item | 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: What are some common types of aluminum coils used in various industrial applications?

- <p>Yes, there are several types of aluminum coils commonly used in industry. These include: 1) Plain aluminum coils, which are used in packaging and construction. 2) Embossed aluminum coils, utilized for decorative purposes and in the automotive industry. 3) Painted aluminum coils, often used in building materials and appliances. 4) Galvanized aluminum coils, which are corrosion-resistant and used in exterior applications. 5) Heat-treated aluminum coils, known for their strength and used in aerospace and automotive parts. Each type serves specific purposes based on the properties of the aluminum and the coatings or treatments applied.</p>

- Q: Is there any specific regulation or standard that dictates the weight of an aluminum coil?

- <p>Yes, there are regulations and standards that dictate the weight of aluminum coils. These are often set by industry standards such as ASTM (American Society for Testing and Materials) and EN (European Norm). The weight of an aluminum coil can vary depending on its thickness, width, and length, and manufacturers must adhere to these standards to ensure consistency and quality. For example, ASTM B 209 specifies the standard for aluminum and aluminum alloy sheet and plate, which includes weight limits. Compliance with these standards is crucial for the safety and performance of products that utilize aluminum coils.</p>

- Q: Can aluminum coils be used in food storage facilities?

- Yes, aluminum coils can be used in food storage facilities. Aluminum is a safe and commonly used material for food storage due to its non-reactive properties and resistance to corrosion, making it suitable for maintaining food quality and preventing contamination.

- Q: Can aluminum coils be used in the production of electronic components?

- Indeed, electronic components can utilize aluminum coils in their production. Aluminum, a highly versatile and extensively employed metal across diverse industries, including electronics, harbors numerous benefits. Notably, it possesses a lightweight nature, exceptional thermal conductivity, resistance to corrosion, and superb electrical conductivity. These remarkable properties render aluminum coils fitting for deployment in electronic components, encompassing capacitors, transformers, inductors, and heat sinks. By incorporating aluminum coils in electronic components, the dissipation of heat becomes more efficient, performance is enhanced, and the overall weight of electronic devices is reduced.

- Q: This question asks for a comparison between aluminum coil and other types of wire, highlighting their differences.

- <p>Aluminum coil is a type of wire made from aluminum, known for its lightweight, high conductivity, and corrosion resistance. It's commonly used in electrical applications, construction, and packaging. Other types of wire, such as copper wire, have different properties. Copper, for instance, has higher conductivity than aluminum but is heavier and more expensive. Steel wire is stronger and more durable but less conductive and prone to rust. The choice between aluminum coil and other wires depends on the specific requirements of strength, conductivity, cost, and environmental resistance for the application in question.</p>

- Q: Can aluminum coils be used for automotive body panels?

- Yes, aluminum coils can indeed be used for automotive body panels. In fact, aluminum is becoming increasingly popular in the automotive industry due to its many advantages. Aluminum is lightweight, which can contribute to improved fuel efficiency and overall performance of the vehicle. Additionally, aluminum has excellent corrosion resistance properties, making it a durable choice for automotive body panels. Moreover, aluminum can be easily formed and molded, allowing for intricate designs and better aerodynamics. Overall, the use of aluminum coils for automotive body panels is a viable option that offers numerous benefits.

- Q: Can aluminum coils be used in the production of cans?

- Yes, aluminum coils can be used in the production of cans. Aluminum is widely used in the manufacturing of cans due to its excellent properties such as lightweight, durability, and corrosion resistance. In the production process, aluminum coils are typically formed into sheets and then cut into the desired size and shape of the can. These sheets are then coated, printed, and formed into cans using various techniques. The use of aluminum coils ensures the production of high-quality cans that are suitable for packaging various beverages and food products.

- Q: What specific conditions or criteria must be met when utilizing aluminum coils?

- <p>There are several special requirements for using aluminum coils. They should be stored in a dry and clean environment to prevent corrosion. The coils must be handled carefully to avoid scratches or dents that could affect their performance. When used in manufacturing, the specific alloy type and temper of the aluminum coil must be considered as they influence properties like strength and malleability. Additionally, the thickness and width of the coil should match the requirements of the application to ensure proper fit and functionality. Adherence to safety standards during the handling and processing of aluminum coils is also crucial to prevent accidents and ensure quality control.</p>

- Q: When the aluminum roll is rolled 0.14, when the coil is taken off, what happened to the loose layer?

- in addition is a kind of expression is down when the aluminum coil suddenly becomes uneven, but the bad effect caused by oil

- Q: I am concerned about the environment so I collect empty aluminum cans off the street when I walk my dog. Right now I have 3 large garbage bags full of crushed aluminum can. The problem is... some of the cans have dirt on and in them. Some of thoroughly flattened ones may even have small pebbles embedded in them. Will these be accepted at the recycling facility? I'm guessing it doesn't matter because when they melt them any organic materials will burn away and any dirt particles or small pebbles will be separated from the molten aluminum. What do you think?

- yes they won't care about dirt

Send your message to us

1050 Aluminum Coil Price ASTM Grade 1060 Aluminum Belt for Solar Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords