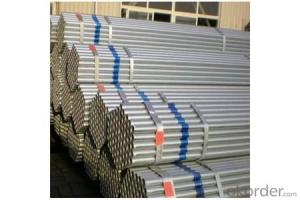

ASTM A53 HOT DIPPED GALVANIZED PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Dip Galvanized seamless steel pipe

Standard: GB,ASTM,DIN,JIS;

Grade: 10#, 20#, 45#, 16Mn;

Length: as customer's demand

Hot Dipped Galvanized Seamless Steel Pipe

1.Standard: ASTM A106,ASTM A53,EN10255,GB/T8162,GB/T8163

2.Material: 10#,20#,ST35,ST37,ST42,ST45

3.Size OD: 18-114.3mm

WT: 2-15mm

Length: 7-12m or according to your requirement.

4.Application: oil and natural gas pipeline, water supply pipeline, boiler, fertilizer factory, chemical

industry, industrial pipeline networks, foundation, construction.

5.Surface: oiled, varnished, black-painted, galvanized, 3PE anti-corrosion, etc

6.Pipe ends:

1). plain end

2). bevelled end

3). both ends threaded, one end with plastic caps protected, the other with socket(couplings) for connecting

4). with hole for casing pipes

5). grooved ends

7.Packing:

1). In bundles, with weaving bags wrapping outside

2). In bare bundles or according to your requirement

- Q: What is the difference between steel pipes and PVC pipes?

- The main difference between steel pipes and PVC pipes lies in their material composition. Steel pipes are made of a durable and strong metal alloy, while PVC pipes are made of a lightweight and flexible plastic called polyvinyl chloride. Steel pipes are typically used for heavy-duty applications that require high strength and resistance to extreme temperatures and pressure, such as in industrial settings or for transporting liquids or gases over long distances. On the other hand, PVC pipes are commonly used for residential and commercial plumbing systems due to their affordability, ease of installation, and resistance to corrosion. Additionally, PVC pipes are not suitable for high-pressure applications and have a lower heat tolerance compared to steel pipes.

- Q: What is the difference between seamless and ERW steel pipes?

- Seamless steel pipes are made without any welded joints, resulting in a uniform and continuous structure. On the other hand, ERW (Electric Resistance Welded) steel pipes are created by welding the edges of the steel strip or coil together, forming a seam. This seam may be visible on the surface of the pipe. While seamless pipes are considered stronger and more reliable due to their uniform structure, ERW pipes are more cost-effective and commonly used for low to medium pressure applications.

- Q: Can steel pipes be used for conveying sewage sludge?

- Yes, steel pipes can be used for conveying sewage sludge. Steel pipes are commonly used in various industrial applications, including the transportation of sewage sludge. They are strong, durable, and resistant to corrosion, making them suitable for handling the potentially corrosive nature of sewage sludge.

- Q: How are steel pipes used in the construction of nuclear power plants?

- Steel pipes are used in the construction of nuclear power plants for various purposes, such as transporting and containing fluids and gases, including coolant, steam, and compressed air. They are specifically chosen for their high strength, durability, and resistance to heat and pressure. Steel pipes are used in the construction of primary and secondary cooling systems, reactor vessels, and other critical components, ensuring the safe and efficient operation of nuclear power plants.

- Q: Which is cheaper, angle iron or steel pipe?

- Angle iron and steel pipe, angle iron is cheap.

- Q: Can steel pipes be used for underground water supply networks?

- Steel pipes are a viable option for underground water supply networks; they possess qualities such as durability, strength, and corrosion resistance. These pipes are commonly employed due to their ability to endure high pressure and bear the weight of the soil and other external forces. Furthermore, steel pipes come in a range of sizes and can be easily welded, making them suitable for diverse water supply system needs. Nevertheless, it is crucial to consider factors like soil quality, the presence of corrosive substances or chemicals, and the necessity of routine maintenance to guarantee the long-lasting effectiveness of steel pipes in underground water supply networks.

- Q: Can steel pipes be used in marine environments?

- Indeed, the usage of steel pipes is viable in marine environments. Steel, being a robust and sturdy material, possesses the capability to endure the severe conditions prevalent in marine surroundings, encompassing saltwater exposure, wave impacts, and corrosion. Nevertheless, it is imperative to meticulously choose the appropriate steel variant and implement suitable protective measures to avert corrosion. Stainless steel and corrosion-resistant alloys are often employed in marine applications due to their exceptional resistance against corrosion and ability to withstand continuous saltwater exposure. Furthermore, the application of coatings such as epoxy or zinc can be an effective means of fortifying steel pipes against corrosion. Consistent maintenance and inspections are also pivotal in ensuring the durability and functionality of steel pipes in marine settings.

- Q: What are the dimensions of steel pipes?

- The dimensions of steel pipes can vary depending on the specific requirements and industry standards. However, steel pipes typically have standardized dimensions in terms of their outer diameter (OD), wall thickness, and length. The outer diameter of steel pipes can range from small sizes, such as ¼ inch (6.35 mm) or ⅛ inch (3.175 mm), to larger sizes like 48 inches (1219.2 mm) or even more for specialty applications. The wall thickness of steel pipes can also vary greatly, with options ranging from thin-walled pipes with a few millimeters of thickness to thick-walled pipes with several inches of thickness. In terms of length, steel pipes are typically produced in standard lengths of 20 feet (6.1 meters) or 40 feet (12.2 meters). However, custom lengths can also be manufactured based on specific project requirements. It is important to note that these dimensions are just general examples and may not cover all the possible variations in steel pipe sizes. Therefore, it is always recommended to consult relevant industry standards and specifications to determine the precise dimensions required for a particular application.

- Q: Seamless steel pipe and welded pipe what is the difference?

- Identification method: see the inside of the pipe, because the external, will deal with the welded pipe is inside a gap, you can see some, some, is not easy to see, you can slowly by hand touch, or see the specifications are relatively thin, welded pipe

- Q: Are steel pipes suitable for high-pressure applications?

- Indeed, steel pipes prove to be an appropriate choice when it comes to high-pressure applications. Renowned for their robustness and endurance, steel pipes are exceptionally well-suited for managing high-pressure scenarios. They possess the remarkable ability to endure the intense internal pressure exerted by fluids or gases without buckling or rupturing. Thanks to their high tensile strength, steel pipes effectively combat the forces that arise in high-pressure environments, thereby ensuring the security and dependability of the piping system. Furthermore, steel pipes can be manufactured with thicker walls, further bolstering their capacity to withstand elevated pressures. Consequently, steel pipes find extensive utilization in various industries, such as oil and gas, petrochemical, power generation, and water distribution, where high-pressure applications are customary.

Send your message to us

ASTM A53 HOT DIPPED GALVANIZED PIPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords