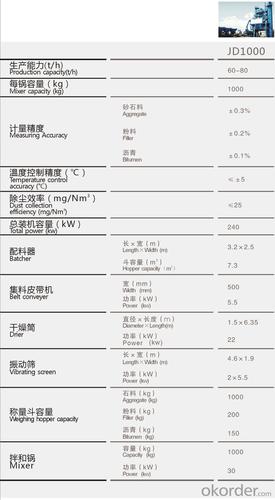

Specifications

JD1000 60-80tons Asphalt Mixing Plant

1. British Parker and Germany BENNINGHOVEN technology.

2. high cost performance.

JD1000 forcing batch type mixing plant is an international advanced product at present. It was designed and manufactured by XRMC after fully absorbing British Parker and Germany BENNINGHOVEN technology. It is specially designed for the market with high performance price ratio featuring easy transferring, installation and space saving. It takes only 25 days for installation and commissioning. It can produce asphalt mixture; modified bitumen mixture, color bitumen mixture and its products meet the various specifications such as express way, high grade road, city road, airport and seaport. With some modification, it can also produce hydraulic asphalt.