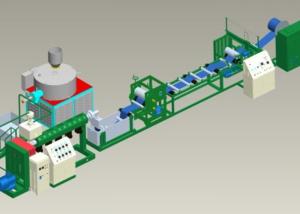

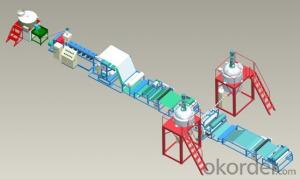

APP Waterproofing Membrane Production Line

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical parameters

1.1 Capacity: Annually output 1.5 million square meter of various types of modified bitumen waterproofing membrane, one shift per day,8 hours per shift,300 days per year ,calculated on basis of 3mm of Products.

1.2 Reinforcement(Base material): Polyester felt:140-300g/M²,Fiberglass felt:150-250 g/ M² , Composite reinforcement(5×5-8×8)

1.3 Modified material: SBS, APP

1.4 Facing material: sand, schist, PE film, Aluminum foil

1.4.1 One side PE film, the other side sand (schist)

1.4.2 One side PE film, the other side aluminum foil

1.4.3 Both sides be with PE film

1.4.4 Embossing or smooth

1.5 Thickness: 2-5 mm

1.6 Linear velocity : 5~25m/min adjustable

1.7 Diesel consumption: 60Kg/h, Thermal efficiency≥73%,oil burning boiler which is of 500000 Kcal to heat conduction oil . The buyer should be responsible for purchasing and installing the boiler.

1.8 Compressed air, 0.7Mpa,0.6 M3/min

Compressed air is used in reinforcement unwinding device, reinforcement splicing device, immersion oil roller, embossing device and semi-automatic winder, etc.

1.9 Total installed capacity: 200KW

1.10 Water consumption: 05T/Day

Cooling water is recycling in cooling pond, suspending cooling water baths and cooling rollers . Buyer should be responsible for cooling pool which of concrete structure with capacity of 200 M3

1.11 200 M3 bitumen storage tank:1 set;

1.5 M3 discharging oil pool:1set

Bitumen storage tank is used to store 100# liquid bitumen, it also can be replaced by a concrete structure (including heating coil)

FAQ:

1. Can we visit factory?

A: Yes, always welcome.

2. Will the engineer go abroad to give install instruction?

A: Yes, our engineer will go to customer's factory to do install support.

3. How long is the production period?

A: It generally takes 45 days for the equipment production.

- Q: The difference between polymer modified asphalt waterproofing membrane and SBS

- SBS modified asphalt waterproof roll and polymer modified asphalt waterproof roll are subordinateSBS modified asphalt waterproof roll is a kind of polymer modified asphalt waterproof rollPolymers are short for polymers and polymersSBS is styrene butadiene styrene block copolymer, which is a kind of high polymer.The polymer modified asphalt waterproof roll includes SBS modified asphalt waterproof roll, APP (APAO) modified asphalt waterproof roll and rubber powder modified asphalt waterproof roll.

- Q: What is the difference between SBS coiled material and APP coiled material?

- SBS and APP mean you want to get to know, they represent two kinds of modifiers, SBS is elastic modifier. APP belongs to plastic modifier, and any kind of coiled material produced belongs to elastomer or plastic waterproof roll.

- Q: Is the construction method of app and SBS waterproof material the same?

- Construction methods are the same.However, the modifier is not the same, about the carcass: APP has glass fiber tire, polyester tire points, SBS is also divided into glass fiber tire and polyester tire.

Send your message to us

APP Waterproofing Membrane Production Line

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords