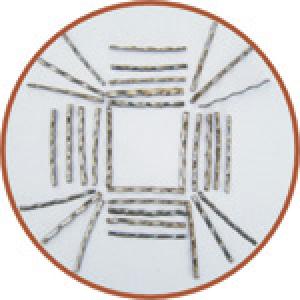

Anchoring nails

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM is the leading supplier of refractory anchors. We have been serving the industry's refractory needs for over 30 years.

Refractory metal is available in hex steel grid, special grid and expanded metal. All material is available in stainless steel and grades T304, T316, T310, T330 as well as all of the standard grades. Other refractory insulation and refractory lining products include wire mesh, expanded metal mesh and hex steel grid.

Refractory anchors and related materials are used for anchoring and assembling refractory ceramic fibre linings or for reinforcing monolithic linings of castables, plastics or ramming mixes. We carry a complete selection of refractory anchors. We can supply you with refractory anchors to suit any depth of lining. Our refractory anchor selection includes studs, V-clips, C-clips, and miscellaneous parts.

- Q: How do steel products contribute to the infrastructure development of cities and urban areas?

- Steel products play a crucial role in the infrastructure development of cities and urban areas. Due to their high strength, durability, and versatility, steel products are widely used in the construction of buildings, bridges, roads, and other essential structures. Steel's ability to withstand heavy loads and extreme weather conditions makes it an ideal choice for constructing tall buildings and long-span bridges, ensuring the safety and longevity of these structures. Additionally, steel's recyclability and sustainability make it an environmentally-friendly choice, contributing to the sustainable development of cities and urban areas. Overall, steel products are essential in creating robust and resilient infrastructure that supports the growth and development of cities and urban areas.

- Q: How is steel used in the manufacturing of mining equipment?

- Steel is used extensively in the manufacturing of mining equipment due to its exceptional strength, durability, and resistance to wear and tear. It is used to construct various components such as drill bits, crushers, conveyor belts, and ore processing machinery, ensuring the equipment can withstand the harsh conditions and heavy loads encountered during mining operations.

- Q: How are steel forgings different from castings?

- Steel forgings and castings are two different manufacturing processes used to produce metal components. The main difference lies in the way each process shapes and forms the metal. Forgings involve the application of pressure or force to shape heated metal, resulting in a stronger and more durable product. On the other hand, castings involve pouring molten metal into a mold and allowing it to solidify, resulting in a less dense and more porous product. In summary, forgings offer superior strength and structural integrity, while castings provide more intricate and complex shapes.

- Q: What are the main properties of steel?

- The main properties of steel include high strength, durability, versatility, and excellent thermal and electrical conductivity. Additionally, steel is known for its corrosion resistance, ease of fabrication, and recyclability.

- Q: How is steel used in the production of HVAC systems?

- Steel is commonly used in the production of HVAC systems due to its strength, durability, and heat-resistant properties. It is used for manufacturing the framework, ductwork, and various components of the system, ensuring stability, longevity, and efficient functioning.

- Q: How is steel used in the production of construction machinery?

- Steel is commonly used in the production of construction machinery due to its strength, durability, and versatility. It is used to manufacture various components such as the chassis, frames, buckets, and booms, providing the necessary structural support and resistance to heavy loads and harsh working conditions. Additionally, steel's ability to be easily molded and welded allows for the creation of complex and intricate machinery designs, ensuring optimal performance and safety on construction sites.

- Q: What are the different types of steel coatings for corrosion prevention?

- Some common types of steel coatings for corrosion prevention include zinc coatings (such as galvanization), epoxy coatings, polyurethane coatings, and ceramic coatings.

- Q: How do steel products withstand extreme temperatures and weather conditions?

- Steel products are able to withstand extreme temperatures and weather conditions due to their inherent strength and durability. Steel is a highly resilient material that can withstand high temperatures without melting or deforming. Additionally, steel is corrosion-resistant, making it resistant to the damaging effects of weather conditions such as rain, snow, and humidity. Furthermore, steel can be coated with protective finishes to enhance its resistance to extreme temperatures and weather, ensuring its longevity and reliability in various environments.

- Q: What are the different types of steel wires and their uses?

- There are several types of steel wires, each designed for specific purposes. Some common types include carbon steel wire, stainless steel wire, galvanized steel wire, and spring steel wire. Carbon steel wire is versatile and used in various applications such as construction, automotive, and manufacturing. Stainless steel wire is corrosion-resistant and commonly used in industries like food processing, medical, and aerospace. Galvanized steel wire is coated with zinc for enhanced durability and is often used in fencing and electrical applications. Spring steel wire has high elasticity and is primarily used to make springs and wire forms in industries like automotive and furniture.

- Q: What are the common types of steel products used in the chemical industry?

- Some common types of steel products used in the chemical industry include stainless steel pipes, tanks, and vessels, as well as steel valves and fittings. These steel products are chosen for their corrosion resistance properties, as they need to withstand harsh chemicals and environments.

Send your message to us

Anchoring nails

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords