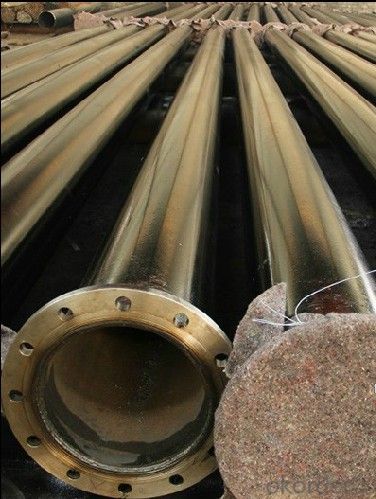

American Standard Pipe Ends Weld Flange Connections

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25-35 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Material: | Carbon Steel | Technics: | Forged | Type: | Union |

| Place of Origin: | China (Mainland) | Model Number: | DN25-DN1000 | ||

| Connection: | Flange | Shape: | Equal | Head Code: | round |

Packaging & Delivery

| Packaging Detail: | standard seaworthy package ,or air transportation package |

| Delivery Detail: | According to ordered quantity and the requirement from Customer |

Specifications

Design expansion joints

Cycle life: 5000 times

Large size available

EJMA code bellows

JIS ANSI DIN BS JB flange

Date:

| Size available | DN25 till DN1000 |

| Material | sus304, 321, 316L... |

| Application temperature | -50 ~ 300 °C |

| Pressure | 0.25MPa - 120MPa |

| Cycle life | 5000 times |

| Structure | bellows, flange, pipe end, internal sleeve, tie-rod, nut |

| Connection type | flange, welded |

| Flange and pipe end | stainless steel, carbon steel |

Features:

Absorb axial & radial & angle displacement.

Absorb Expansion and Contraction of temperature cause.

Resolve minor deviation, eliminate pipeline residual stress.

Reduce mounting bracket & improve economic performance.

Easy cleaning and maintenance.

Used for chemical / metallurgy / electricity / shipbuilding / construction and other industries.

Pipe Ends Weld Flange Connections Image

FAQ of Pipe Ends Weld Flange Connections

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard.Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: How are steel pipes classified according to their wall thickness?

- Steel pipes are classified according to their wall thickness into three categories: schedule, standard, and extra strong.

- Q: The difference between 12Cr1MoVG alloy steel tube and 15CrMo

- With this kind of steel manufacturing products, usually by heat treatment (normalizing and tempering); parts made before use, usually need to go through refining or chemical surface treatment (carburizing and nitriding), surface quenching or high-frequency quenching treatment. Therefore, according to the chemical composition (mainly carbon content), heat treatment process and use of different, such steel can be roughly divided into carburizing, quenching and tempering and nitriding steel three.

- Q: What are the common applications of galvanized steel pipes?

- Galvanized steel pipes are commonly used in various industries and applications such as plumbing, water supply systems, gas pipelines, electrical conduits, construction projects, fencing, and outdoor structures. The galvanization process adds a protective zinc coating to the steel, making it resistant to corrosion and extending its lifespan, making it ideal for applications requiring durability and longevity.

- Q: What are the different types of thread connections used in steel pipes?

- There are several types of thread connections commonly used in steel pipes, including tapered threads such as NPT (National Pipe Taper), which are designed to create a tight seal, and straight threads like NPS (National Pipe Straight), which are often used for mechanical applications. Additionally, some other types of thread connections used in steel pipes include BSP (British Standard Pipe), which is widely used in Europe, and API (American Petroleum Institute) threads, which are commonly used in the oil and gas industry.

- Q: What is the maximum bending radius for steel pipes?

- The maximum bending radius for steel pipes typically depends on the specific grade and diameter of the pipe, but generally, it ranges from three to five times the pipe's outer diameter.

- Q: How are steel pipes protected against seismic activities?

- Steel pipes are protected against seismic activities through various measures such as designing them to be flexible and resilient, using seismic joints and hangers, and implementing proper anchoring and support systems. Additionally, steel pipes are often coated with protective materials to enhance their resistance to corrosion and other external factors that may be triggered by seismic events.

- Q: What are the different types of steel pipe coatings for drinking water pipelines?

- There are several types of steel pipe coatings used for drinking water pipelines, including fusion bonded epoxy (FBE), polyethylene (PE), and polyurethane (PU) coatings. Each coating offers different advantages, such as corrosion resistance, durability, and smoothness, to ensure the safety and quality of drinking water.

- Q: Can steel pipes be used for paper mills?

- Yes, steel pipes can be used for paper mills. Steel pipes are commonly used in paper mills for various purposes such as transporting fluids, chemicals, and steam within the facility. They are known for their durability, strength, and resistance to corrosion, making them suitable for the harsh conditions and high-pressure requirements of paper mill operations.

- Q: What are the common challenges faced during steel pipe installation?

- Some common challenges faced during steel pipe installation include obtaining accurate measurements and ensuring proper alignment, dealing with obstructions or difficult terrain, managing the weight and size of the pipes, ensuring proper sealing and connections, and adhering to safety regulations and protocols.

- Q: What are the common applications of seamless steel pipes?

- Due to their unique properties, seamless steel pipes are widely used in various industries. Here are some of the most common applications: 1. The oil and gas industry extensively utilizes seamless steel pipes for transporting oil, gas, and other fluids. These pipes are preferred because of their high strength, durability, and resistance to corrosion, making them suitable for harsh environments. 2. Seamless steel pipes are extensively used in construction projects, such as building, bridge, and tunnel construction. They are ideal for structural applications due to their ability to withstand heavy loads and provide excellent strength and stability. 3. The automotive industry relies on seamless steel pipes for manufacturing automotive parts, including exhaust systems, engine components, and hydraulic systems. These pipes offer high strength, reliability, and resistance to heat, making them suitable for demanding automotive applications. 4. Various mechanical and engineering applications benefit from the usage of seamless steel pipes. They are commonly used for carrying fluids, gases, and steam, as well as for transmitting power in machinery and equipment. 5. Power plants extensively utilize seamless steel pipes for transporting steam and hot water. These pipes are capable of withstanding high pressure and temperature, making them ideal for power generation applications. 6. The petrochemical industry heavily relies on seamless steel pipes for transporting chemicals, gases, and liquids. These pipes have excellent resistance to corrosion, which is essential when dealing with hazardous and corrosive substances. 7. The mining industry utilizes seamless steel pipes for various applications, including the transportation of slurry, water, and other mining-related fluids. These pipes offer durability, reliability, and resistance to abrasion, making them suitable for the challenging mining environment. 8. The aerospace industry finds applications for seamless steel pipes in manufacturing aircraft components, such as hydraulic systems, fuel lines, and structural parts. These pipes provide a high strength-to-weight ratio and resistance to extreme temperatures and pressure. Overall, seamless steel pipes play a crucial role in a wide range of industries. Their exceptional properties, including strength, durability, resistance to corrosion and high temperatures, make them an essential component in various industrial processes and infrastructure development.

Send your message to us

American Standard Pipe Ends Weld Flange Connections

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25-35 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords