Amazon Paper Packaging Tape - BOPP Tape, Aluminum Foil Tape, Industry Tape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of BOPP Tape Description

Widely used for cartom sealing and packing,light duty packing, bounding, holding and other office and household use.

2. Main Features of the BOPP Tape

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

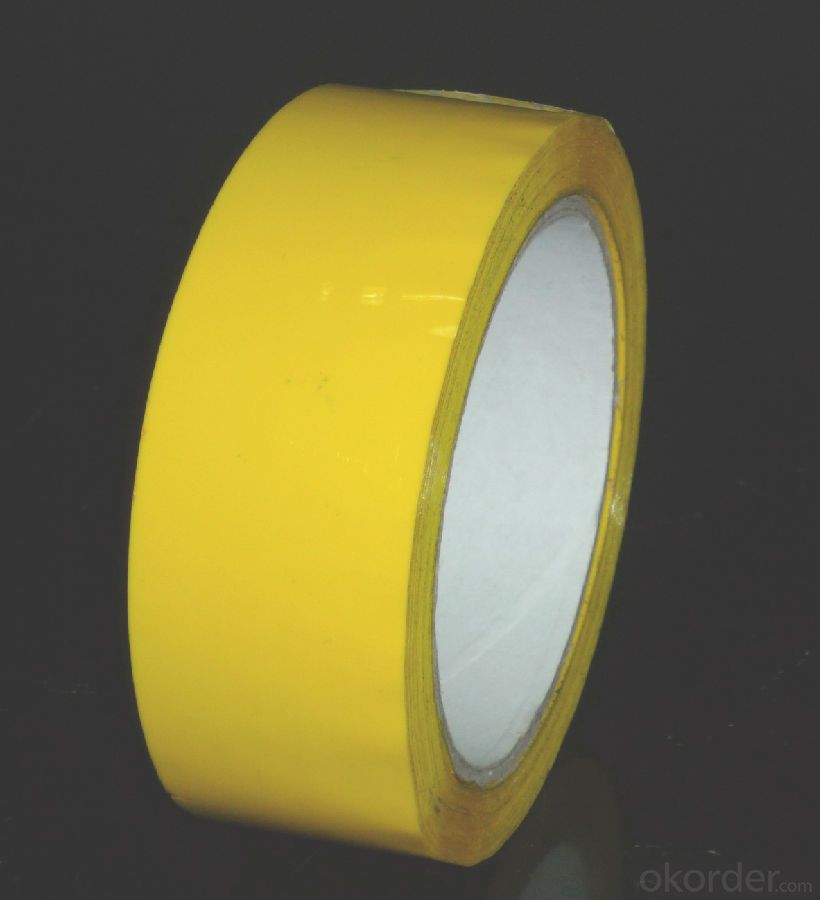

3. BOPP Tape Images

4. TYPICAL PHYSICAL PROPERTIES:

CONSTRUCTION:

Carrier: BOPP film

Adhesive: Water based acrylic adhesive.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + carrier): 42 ± 1 um

Adhesive thickness:20 ± 1 um

Initial Tack: ³ 23#

180O Peel Adhesion (to steel): ³ 6.52 N /25mm

Holding Power: ³ 31 hrs

Item No. | Carrier | Adhesive | Total | Initial | Peel Adhesion | Elongation |

BP-40 | BOPP film | water based acrylic | 40 micron | >18# | 0.5kgf/25mm | <180%< span=""> |

BP-45 | BOPP film | water based acrylic | 45 micron | >18# | 0.5kgf/25mm | <180%< span=""> |

BP-50 | BOPP film | water based acrylic | 50 micron | >20# | 0.5kgf/25mm | <180%< span=""> |

BP-65 | BOPP film | water based acrylic | 65 micron | >24# | 7.88N/25mm | <180%< span=""> |

5.Advantage To Recommend:

We supply a wide range of products, which include double sided adhesive tape, masking tape, kraft tape, cloth tape, BOPP tape and so on.

Our biggest item is double side tape. Our double-sided adhesive tapes are with the carriers of tissue, PET, OPP, cloth, PE foam and EVA foam. And the adhesives involved are water based, solvent based and hot-melt acrylic adhesive.

According to different temperature resistances, we have two categories of masking tapes separately for general purpose and high temperature from 100°C to 160°C.

We also produce kraft tape, cloth tape and BOPP tape.

We have as our principle “Clients’ need comes first”. So we have a good variety of technical properties and sizes to meet with your different needs.

Our products enjoy popularity in markets because they have super quality with competitive price and good service.

Adhero is your ideal choice for excellent adhesive tapes and solutions.

6. FAQ:

1)What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2)What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3)How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4)Can Adhero accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5)What are the international commodity codes for these products?

HS Code: 48231900.

6)Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

7)What are the temperatures resistances of your masking tape?

we have two general kinds of masking tapes separately for general purpose 60°C and high temperature 100°C to 160°C.

8)Are you a manufacturer or just a trader?

We are a professional manufacturer.

9)How about the quality?

The quality is very good. We have large and advanced product line.welcome to visit our company.

- Q: Can packaging tape be used for sealing foam?

- Yes, packaging tape can be used for sealing foam. Packaging tape is commonly used for sealing boxes and packages, but it can also be used effectively to seal foam. When using packaging tape to seal foam, it is important to ensure that the tape is securely adhered to the foam surface to create a tight seal. This can be achieved by applying pressure to the tape after it has been applied. Additionally, it is recommended to use a tape that is specifically designed for sealing foam, as these tapes often have stronger adhesive properties and are more resistant to temperature changes and moisture. Overall, packaging tape can be a convenient and effective option for sealing foam.

- Q: Can packaging tape be used for sealing packages with electronics or electrical components?

- Sealing packages containing electronics or electrical components with packaging tape is possible. However, it is essential to understand that not all packaging tapes are suitable for this purpose. To ensure the safety of the items, it is advised to opt for an anti-static or ESD-safe tape. These tapes are specifically crafted to shield sensitive electronic components from static electricity during transportation or handling. Using regular packaging tape lacking anti-static properties may expose the electronics to the risk of static discharge, potentially leading to damage or compromised performance. Therefore, it is crucial to carefully assess the specific requirements of the electronics being packaged and select an appropriate tape accordingly, guaranteeing their protection.

- Q: Can packaging tape be used for sealing plastic lunch boxes?

- Yes, packaging tape can be used for sealing plastic lunch boxes.

- Q: Is packaging tape easy to tear by hand?

- Yes, packaging tape is generally easy to tear by hand.

- Q: How does packaging tape perform when exposed to sunlight?

- Packaging tape typically performs well when exposed to sunlight, especially if it is made from durable materials like acrylic or polypropylene. These tapes are designed to resist UV rays and maintain their adhesive properties even when exposed to sunlight for extended periods. However, it is always recommended to check the specifications of the specific tape you are using, as some may have limitations or may be prone to deterioration or discoloration when exposed to direct sunlight for prolonged periods.

- Q: Can packaging tape be used for sealing packages with irregular shapes?

- Indeed, when it comes to sealing packages with irregular shapes, packaging tape comes in handy. Its flexibility and adhesive nature make it perfect for securing packages of different sizes and contours. Thanks to its strong adhesive properties, packaging tape can adhere to various surfaces, even those that are uneven or irregular, ensuring that the package remains tightly sealed during transportation. Moreover, packaging tape is known for its durability and tear-resistance, providing an added layer of protection for the package. Consequently, whether the package boasts an irregular shape or not, packaging tape proves to be a dependable and efficient choice for sealing it securely.

- Q: Does packaging tape have a specific shelf life?

- Yes, packaging tape does have a specific shelf life. The shelf life of packaging tape typically depends on the type and quality of the tape. However, most packaging tapes have a shelf life of around 1 to 2 years if stored properly in a cool, dry place. It is always recommended to check the manufacturer's guidelines for specific information on the shelf life of a particular packaging tape.

- Q: What are the common sizes and lengths of packaging tape rolls?

- Common sizes and lengths of packaging tape rolls vary depending on the brand and purpose. However, standard packaging tape rolls typically come in widths of 1.88 inches (48mm) and lengths ranging from 55 yards (50 meters) to 110 yards (100 meters).

- Q: Can packaging tape be used for sealing plastic toolboxes?

- Indeed, plastic toolboxes can be effectively sealed using packaging tape. Specifically crafted to securely seal boxes and packages, packaging tape exhibits versatility by being suitable for various materials, including plastic. It delivers a robust and long-lasting seal capable of enduring regular handling and transportation. Nevertheless, for extended storage or heavy-duty purposes, it is advisable to opt for a more robust and specialized tape, like duct tape or strapping tape, as they provide enhanced durability and adhesion.

- Q: Does packaging tape have a specific weight capacity?

- Yes, packaging tape does have a specific weight capacity. The weight capacity of packaging tape depends on its thickness, width, and quality. Generally, packaging tapes are designed to securely seal boxes and packages, and their weight capacity is determined by their adhesive strength and durability. Most standard packaging tapes have a weight capacity of around 20 to 30 pounds. However, heavy-duty packaging tapes are available that can handle weights of up to 50 pounds or more. It is important to consider the weight of the package or box being sealed and choose a packaging tape that can handle the specific weight capacity to ensure a secure and reliable seal.

Send your message to us

Amazon Paper Packaging Tape - BOPP Tape, Aluminum Foil Tape, Industry Tape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords