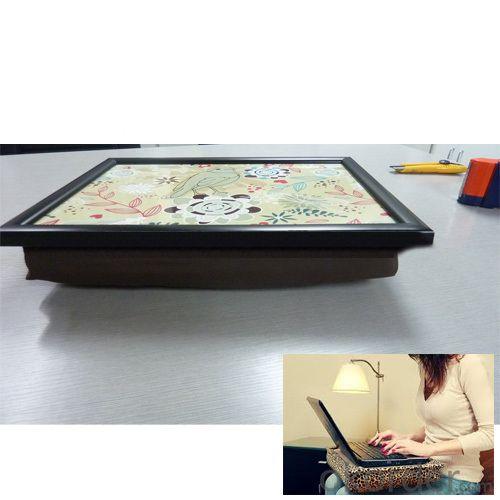

Cushion Lap Tray Hot Selling

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Sets pc

- Supply Capability:

- 600,000 Set/Sets per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.ASTM A106/A53 GR.B

2.Outer diameter:10.3-194.4mm

3.Wall thickness:6.5-59mm

4.Cer:ISO9001:2008,API

Seamless steel pipe

(1) Standard: GB8163, ASTM A106/A53/API 5L

(2) Material: 10#, 20#, 16Mn, A106Gr.A/B/C,

(3)Specification: O.D: 21.3mm-711.2 mm

(4) W.T: 2.11mm-59.54mm

Technical Parameters of Seamless Steel Pipe

A53: Chemical components and mechanical property

Stan- dard | Trade mark | Chemical components | Mechanical property | ||||||||||

| C | Si | Mn | P,S | Cu | Ni | Mo | Cr | V | Tensile Strength | Yield Strength | Elongation | ||

ASTM A53 | A | ≤0.25 | / | ≤0.92 | ≤0.05 | ≤0.06 | ≤0.40 | ≤0.15 | ≤0.40 | ≤0.08 | ≥330 | ≥205 | ≥29.5 |

| B | ≤0.30 | / | ≤1.2 | ≤0.05 | ≤0.06 | ≤0.40 | ≤0.15 | ≤0.40 | ≤0.08 | ≥415 | ≥240 | ≥29.5 | |

A106: Chemical components and mechanical property

| Stan-dard | Trade mark | Chemical components | Mechanical property | ||||||||||

| C | Si | Mn | P,S | Cu | Ni | Mo | Cr | V | Tensile Strength | Yield Strength | Elongation | ||

ASTM A106 | B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.40 | ≤0.08 | ≥415 | ≥240 | ≥30 |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.40 | ≤0.08 | ≥485 | ≥275 | ≥30 | |

PSL 1: Chemical components and mechanical property

| Class and Sort | Chemical components | Mechanical property | |||||||

| C(Max) | Mn(Max) | P(Max) | S(Max) | Tensile Strength(Min) | Yield Strength(Min) | ||||

| A25 | CL I | 0.21 | 0.60 | 0.030 | 0.030 | 45.000 | 310 | 25.000 | 172 |

| CL II | 0.21 | 0.60 | 0.030 | 0.030 | |||||

| A | 0.22 | 0.90 | 0.030 | 0.030 | 48.000 | 331 | 30.000 | 207 | |

| B | 0.28 | 1.20 | 0.030 | 0.030 | 60.000 | 414 | 35.000 | 241 | |

| X42 | 0.28 | 1.30 | 0.030 | 0.030 | 60.000 | 414 | 42.000 | 290 | |

| X46 | 0.28 | 1.40 | 0.030 | 0.030 | 63.000 | 434 | 46.000 | 317 | |

| X52 | 0.28 | 1.40 | 0.030 | 0.030 | 66.000 | 455 | 52.000 | 359 | |

| X56 | 0.28 | 1.40 | 0.030 | 0.030 | 71.000 | 490 | 56.000 | 386 | |

| X60 | 0.28 | 1.40 | 0.030 | 0.030 | 75.000 | 517 | 60.000 | 414 | |

| X65 | 0.28 | 1.40 | 0.030 | 0.030 | 77.000 | 531 | 65.000 | 448 | |

| X70 | 0.28 | 1.40 | 0.030 | 0.030 | 82.000 | 565 | 70.000 | 483 | |

Our catalog of Seamless steel pipe

| item | material | standard | specification (OD*WT)mm | usage |

| alloy pipe | Cr5Mo. 15CrMo 13CrMo44 12Cr1MoV P22 T91,P91,P9, T9 Wb36 | GB5310-95 GB9948-88 ASTMA335/A335M ASTMA213/213M DIN17175-79 JISG3467-88 JISG3458-88 | 16-824*2-100 | The seamless steal pipes features resistance to high pressure, high/low temperature and corrosion and is used in the industries of petroleum, chemical engineering and. Electric power as well as boiler |

High-pressure boiler pipe | 20G,A106, ST 45 | GB5310-95 ASTM A 106-99 DIN17175-79 | 14-630*2-80 | Temperature-resistant seamless steel pipe far high-pressure boiler |

Seamless pipes for petroleum | 20, 12CrMo, 15CrMo | GB9948-88 | 10-530*1.5-36 | Boiler pipes for refinery, heat-exchanging pipes, seamless steel pipes for pipeline |

High-pressure Seamless pipes for fertilizer making equipment | 20, 16Mn, Q345 | GB6479-2000 | 18-530*3-40 | Fertilizer making equipment and pipe line |

Low and medium- pressure boiled pipe | 10,20 | GB3087-1999 | 10-530*2-40 | Over-heat pipe for low and medium pressure boiler, boiling water pipe, locomotive smoke pipe(big and small) |

| Fluid pipe | 20, Q345 | GB/T8163-1999 | 8-630*1.0-40 | Fluid feeding |

| Structural pipe | 20, Q345 10, 20,35,45, 16Mn,Q345B | GB/T8162-1999 | 6-1020*1.5-100 | For common structure |

| Line pipe | Gr.B | API | 60-630*1.5-40 | Carrying gas, water or oil in the industries of petroleum and natural gas |

Hydraulic prop pipe | 27SiMn | GB/T17396-1998 | 70-377*9-40 | Hydraulic support and prop |

- Q: Can steel pipes be used for underground cooling systems?

- Yes, steel pipes can be used for underground cooling systems. Steel pipes are commonly used in various applications, including underground cooling systems, due to their durability, strength, and resistance to corrosion. They can effectively handle the high pressure and temperature demands of cooling systems. Additionally, steel pipes can be welded or threaded together, allowing for easy installation and maintenance. However, it is important to ensure that the steel pipes are properly coated or insulated to prevent corrosion and maintain efficiency in heat transfer.

- Q: What is the tensile strength of steel pipes?

- The tensile strength of steel pipes can vary depending on the grade and type of steel used. However, in general, steel pipes have a high tensile strength. Typically, carbon steel pipes have a tensile strength range of 370 to 700 megapascals (MPa), while alloy steel pipes can have a tensile strength range of 770 to 1200 MPa. These high tensile strengths allow steel pipes to withstand high levels of pressure and stress, making them suitable for a wide range of applications such as in the construction, oil and gas, and automotive industries. It is important to note that the tensile strength of steel pipes can also be influenced by other factors such as the manufacturing process, heat treatment, and the presence of any defects or imperfections. Therefore, it is advisable to consult the specifications provided by the manufacturer or industry standards to determine the exact tensile strength of a specific steel pipe.

- Q: Can steel pipes be used for steam distribution?

- Yes, steel pipes can be used for steam distribution. Steel pipes are commonly used for conveying steam due to their high heat resistance and durability. They can withstand the high temperatures and pressures associated with steam distribution, making them a suitable choice for this application.

- Q: What are the different types of steel pipe fittings?

- There are several types of steel pipe fittings, including elbows, tees, couplings, unions, reducers, caps, plugs, and crosses.

- Q: What are the different types of steel pipe reducers?

- There are several types of steel pipe reducers, including concentric reducers, eccentric reducers, and reducing tees.

- Q: What is the purpose of galvanizing steel pipes?

- The purpose of galvanizing steel pipes is to protect them from corrosion and increase their lifespan.

- Q: Hot galvanized steel pipe for use?

- Hot galvanized pipe: in order to improve the corrosion resistance of steel pipe, galvanized steel pipe. Galvanized steel pipe hot galvanized and galvanized two kinds, hot galvanized, zinc coating thickness, zinc plating cost is low, the surface is not very smooth.The hot-dip galvanized pipe is an alloy layer that causes molten metal to react with the iron matrix, thus combining the substrate with the two coating. Hot dip galvanizing is the first steel pickling, in order to remove iron, steel pipe surface after pickling, cleaning by ammonium chloride or zinc chloride solution or ammonium chloride and zinc chloride aqueous solution tank, and then into the hot dip tank. Hot galvanizing has the advantages of uniform coating, strong adhesion, long service life and so on. A complex physical and chemical reaction is formed between the steel tube matrix and the molten plating solution to form a corrosion resistant structure with a tight zinc - iron alloy layer. The alloy layer is integrated with the pure zinc layer and the steel pipe matrix. Therefore, it has strong corrosion resistance.

- Q: Are steel pipes suitable for chemical processing plants?

- Due to their exceptional strength, durability, and corrosion resistance, steel pipes find common usage in chemical processing plants. Particularly, stainless steel or alloy steel pipes possess the ability to endure high temperatures, pressure, and the corrosive impact of various chemicals. Consequently, they serve as a suitable means for the safe and efficient transportation and containment of diverse chemical substances. Moreover, the installation, maintenance, and repair of steel pipes are hassle-free, rendering them a cost-effective option for chemical processing plants. Nonetheless, it remains crucial to carefully select the appropriate steel type, taking into account factors such as the specific chemicals being processed, operating conditions, and any potential risks or compatibility issues. Regular inspections and maintenance are also vital for ensuring the integrity and performance of steel pipes in chemical processing plants.

- Q: How do you measure the thickness of steel pipes?

- One common method to measure the thickness of steel pipes is to use a specialized tool called a pipe thickness gauge. This device consists of a small, handheld instrument with a probe that is inserted into the pipe. By applying pressure to the probe, the gauge can accurately determine the thickness of the pipe's wall. Additionally, ultrasonic testing can also be employed to measure the thickness by sending sound waves through the pipe and analyzing the reflections.

- Q: What are the different types of steel pipe coatings for chemical processing plants?

- There are several types of steel pipe coatings commonly used in chemical processing plants, including epoxy, polyethylene, polyurethane, and fusion-bonded epoxy (FBE) coatings. Each coating offers different benefits such as corrosion resistance, chemical resistance, and enhanced durability, which are crucial for protecting steel pipes against the harsh conditions and corrosive substances found in chemical processing plants.

Send your message to us

Cushion Lap Tray Hot Selling

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Sets pc

- Supply Capability:

- 600,000 Set/Sets per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords