Aluminum Strips Lowes New Product Coil Aluminum Composite Panel Roller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Stable aluminium is created when hydrogen fuses with magnesium, either in large stars or in supernovae. It is estimated to be the 14th most common element in the Universe, by mass-fraction. However, among the elements that have odd atomic numbers, aluminium is the third most abundant by mass fraction, after hydrogen and nitrogen.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

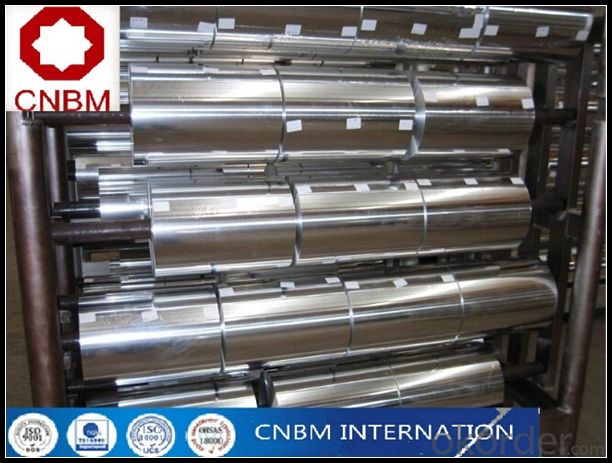

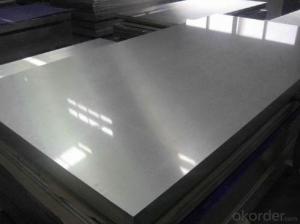

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Is it possible to utilize aluminum strips for creating signs or banners?

- <p>Yes, you can use aluminum strips to make signs or banners. Aluminum is lightweight, durable, and resistant to weather, making it a popular choice for outdoor signage. It can be cut, bent, and shaped easily to create various designs. Additionally, aluminum strips can be painted or printed on, allowing for customization with text and graphics. However, ensure that the aluminum is of the appropriate thickness and quality for your specific project to maintain its structural integrity and longevity.</p>

- Q: What are the various kinds of flooring options available that utilize aluminum strips in their construction?

- <p>Aluminum strip flooring comes in several types, each with unique characteristics. One common type is aluminum strip laminate flooring, which combines aluminum strips with a laminate surface for durability and style. Another is aluminum strip interlocking flooring, known for its easy installation and resistance to moisture. There's also aluminum strip parquet flooring, which mimics the look of wood parquet but with the benefits of aluminum. Lastly, aluminum strip modular flooring is popular for its versatility and ability to be easily replaced or reconfigured. Each type offers different benefits, such as resistance to wear, moisture, and heat, making them suitable for various environments, from residential to commercial settings.</p>

- Q: Are aluminum strips suitable for manufacturing automotive components?

- <p>Yes, aluminum strips are commonly used for automotive parts due to their lightweight, high strength, and corrosion resistance. They are utilized in various components such as engine parts, body panels, and suspension systems to reduce weight and improve fuel efficiency. Additionally, aluminum's recyclability makes it an environmentally friendly choice for the automotive industry.</p>

- Q: Is it possible to use aluminum strips as a material for wall cladding?

- <p>Yes, aluminum strips can be used for wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for both interior and exterior applications. Aluminum strips are also easy to install and maintain, and they can be painted or finished in various ways to match different architectural styles. However, it's important to ensure that the aluminum is of high quality and that the installation is done correctly to achieve a secure and aesthetically pleasing result.</p>

- Q: Classification of aluminium strips of aluminium strips

- There are specific uses: aluminum aluminum (aluminum foil transformer) transformer, high frequency welding hollow aluminum strip, aluminum strip used for aluminum fin radiator belt, cable aluminum strip, aluminum strip, aluminum strip punching with aluminum belt etc..

- Q: What characteristics or attributes are typically associated with aluminum strips?

- <p>Aluminum strips possess several properties that make them versatile in various applications. They are lightweight, strong, and have good thermal and electrical conductivity. Aluminum strips are also corrosion-resistant, which makes them suitable for outdoor use. They exhibit good ductility, allowing them to be easily bent and shaped without breaking. Additionally, they have a high reflectivity, which is useful in applications requiring light reflection. Aluminum strips are non-magnetic and can be easily recycled, contributing to their sustainability.</p>

- Q: This question asks for advice on choosing high-quality aluminum strip roofing materials.

- <p>When selecting quality aluminum strip roofing materials, consider the following tips: 1. Gauge Thickness: Opt for a thicker gauge for increased durability and resistance to weathering. 2. Coating: Look for materials with a protective coating, such as Kynar 500 or Hylar 5000, which offer superior resistance to fading and chalking. 3. Color Options: Choose materials with a wide range of color options to match your home's aesthetic. 4. Energy Efficiency: Select materials with high solar reflectance to reduce cooling costs. 5. Manufacturer Reputation: Research the reputation of the manufacturer for quality and reliability. 6. Certifications: Ensure the materials meet industry standards and certifications, such as the American Society for Testing and Materials (ASTM). 7. Warranty: A good warranty is a sign of confidence in the product's quality and longevity. 8. Installation: Consider the ease of installation and whether the material requires specialized tools or techniques.</p>

- Q: Describe how the weight of an aluminum strip compares to other common roofing materials.

- <p>An aluminum strip is significantly lighter than many other roofing materials. It weighs approximately 1.5 to 2.5 pounds per square foot, depending on the thickness and profile. In contrast, asphalt shingles can weigh between 2.5 to 4.5 pounds per square foot, while concrete tiles can be as heavy as 7 to 10 pounds per square foot. Clay tiles are also heavier, typically ranging from 6 to 8 pounds per square foot. This makes aluminum strips an attractive option for those seeking a lightweight roofing solution.</p>

- Q: How can the aluminium band be welded to the steel shell?

- Aluminum strip can be welded to the steel shell, mainly to see the aluminum strip thickness, to select the welding method and welding materials according to thickness.

- Q: What factors should be considered to determine if an aluminum strip is suitable for a specific application?

- <p>To determine if a certain type of aluminum strip is suitable for your application, consider the following factors: mechanical properties such as strength and ductility, corrosion resistance, thermal conductivity, and electrical conductivity. Assess the strip's dimensional tolerances and surface finish to ensure they meet your requirements. Check if the strip's formability and weldability align with your manufacturing processes. Also, consider the strip's weight and cost-effectiveness. It's advisable to consult with a material scientist or supplier who can provide specific recommendations based on your application's unique needs.</p>

Send your message to us

Aluminum Strips Lowes New Product Coil Aluminum Composite Panel Roller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords