Aluminum Silicate Fire Brick - Refractory Silica Brick for Hot-Blast Stoves S-95

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

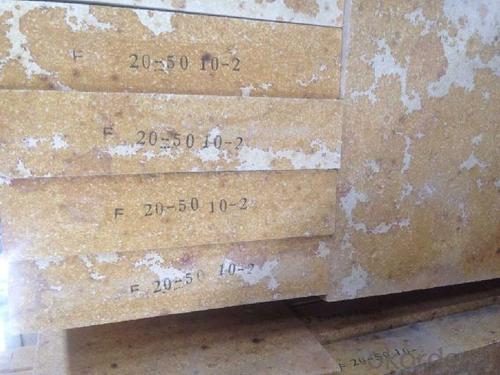

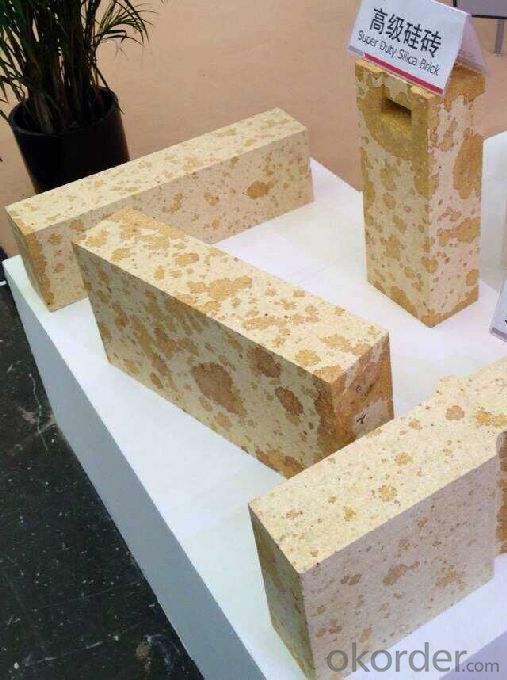

CMAX silica brick is a kind of acid refractory product which is mainly made of tridymite and cristobalite, and a small amount of quartz and vitreous. CMAX Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Application

Coke oven

Hot blast stoves

Glass furnace

Features

High refractoriness under load

Superior resistance to acids (including oxidizing)

Resistance to chlorine

Resistance to thermal shock and pressure changes

Low thermal and chemical expansion

Technical Data

ITEM | For Hot-Blast Stoves | For Glass Furnace | ||||||

S-94 | S-95 | S-95B | G-94 | G-95A | G-95B | G-96A | G-96B | |

SiO2, % | ≥ 94 | ≥ 95 | ≥ 95 | ≥ 94 | ≥ 95 | ≥ 95 | ≥ 96 | ≥ 96 |

Fe2O3, % | ≤ 1.5 | ≤ 0.5 | ≤ 1 | ≤ 1.5 | ≤ 1.2 | ≤ 1.2 | ≤ 0.8 | ≤ 1 |

Residual Quartz, % | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ||||

Apparent Porosity | ≤ 23 | ≤ 23(24) | ≤ 21(23) | ≤ 24 | ≤ 22(24) | ≤ 22(24) | ≤ 22(24) | ≤ 22(24) |

True Density, g/cm 3 | ≤ 2.35 | ≤ 2.34 | ≤ 2.33 | ≤ 2.35 | ≤ 2.35 | ≤ 2.34 | ≤ 2.34 | |

Cold Crushing Strength, Mpa | ≥ 29.4 | ≥ 30(27) | ≥ 30(20) | ≥ 30 | ≥ 30(35) | ≥ 30(35) | ≥ 30(35) | ≥ 30(35) |

Refractoriness Under Load, º C | ≥ 1650 | ≥ 1600 | ≥ 1630 | ≥ 1660 | ≥ 1650 | ≥ 1680 | ≥ 1670 | |

Permanent Linear Change, % | 1500º CX4h, ± 0.2 | 1450º CX2h, ± 0.5 | ||||||

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: Why will expand when heated brick

- In the process of SiO2 drying, the four crystalline transformation points of 117, 163, 180~270 and 573 DEG C are found, among which the volume expansion caused by the 180~270 is the largest.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The use of high thermal conductivity of silica brick, reducing coke fuel consumption, reduce emissions of pollutants such as NOx, with considerable economic benefits and social benefits, is the future direction of the new technology of using coke oven refractory.

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Tridymite content high thermal conductivity silica brick is 70%, tridymite content of traditional brick is 60%, tridymite content high thermal conductivity of silica brick than tridymite high content of 10% traditional brick,

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- The content of SiO2 is 98.23% crystalline silica as raw material, with sulfite pulp liquid as binder, millscale and lime as mineralizer, by Jin Hongshi (TiO2) as additive, can improve the rate of thermal conductivity of silica brick for coke oven. When the rutile content is 1.5%, the coefficient of thermal conductivity of silica brick for coke oven is 2.66W/ (m.k).

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

- Q: The formula in the refractory brick, and firing curve, who knows?

- By silica powder, 81-85%, perlite 15-19%, plus the total weight of the main raw materials of the following accessories

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Aluminum Silicate Fire Brick - Refractory Silica Brick for Hot-Blast Stoves S-95

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords