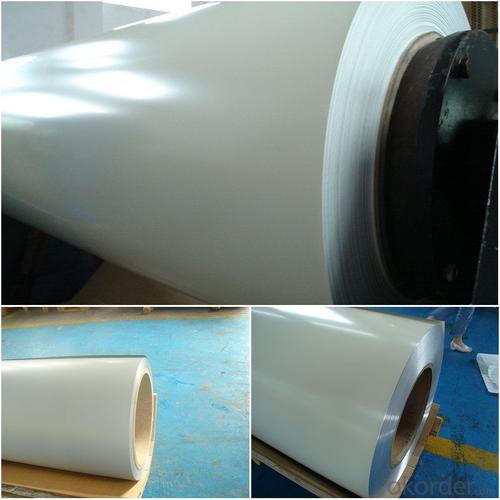

Aluminum Polyester Color Coated Coil Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colorcoated aluminum magnesium alloy Al-Mn

Second,the Al-Mn-Mg alloys the characteristics of color coated aluminum

Colorcoated aluminum magnesium alloy Al-Mn alloy is used for the 3004 state of theAl-Mn-Mg aluminum alloy substrate, after de-ester, cleaning, passivation layerprocessing, and then painting on this basis, the international most advancedlevel of KANAR500 and HYLAR5000 Series Fluorocarbon (PVDF) resin coating, thecolor coated aluminum manganese alloy known international companies use theU.S. PPG, Sweden and the United States Weishi Bo Beca companies paint company,its products by the natural light exposure, Florida testing, with more than 20years of weathering quality assurance. Color coated aluminum magnesium alloyAl-Mn advantages of raw materials, its products have a high strength, corrosionresistance, high weather resistance and other characteristics, and according totheir own customers were asked to choose a different color palette, you cancolor integration, can co-exist to gorgeous effect.

Third,Al-Mn-Mg alloys the use of color coated aluminum

Ourcompany specializes in aluminum color coated aluminum manganese alloy has beenwidely used in large factories, exhibition halls, stadiums, airports, trainstation roof and ceiling decorative envelope system board. Thickness of thealuminum can choose different color coated aluminum magnesium alloy ofmanganese, by cutting, pressing, punching, bending and other follow-up moldingprocess for large span, the larger the overall roof, wall decorative panelsused in construction; You can also cut into small panels by bending, stampingmold, etc., for indoor decorative roof plate; also with polyurethane foam,bonded aluminum honeycomb composite construction for energy-saving decorativewall plates.

Fourth,the development prospects

As the field of building decoration materials, the continuous improvementrequirements, as poor performance of color coated steel corrosion, rust, yellowrust after a large amount of the deficiency of serious impact on the building'soverall appearance, the urgent need to develop a color plate with bothstrength, but also overcome the shortcomings of color-coated steel, while thereare long-term durability of new materials, building decoration, used inairports, commercial buildings, train stations, subways, hospitals and otherarchitectural decoration. The Al-Mn-color coated aluminum magnesium alloymaterials precisely meet these requirements, with the expanding domesticdemand, strengthen public infrastructure under the principle of color coatedaluminum magnesium alloy of manganese will become an increasingly widespreaduse of aluminum, a good prospect.

- Q: This question asks whether exposure to aluminum can lead to allergic reactions.

- <p>While aluminum is one of the most abundant elements on Earth and is commonly used in various products, most people do not experience allergic reactions to it. However, a small percentage of individuals may have an allergy to aluminum, which can cause contact dermatitis or other allergic responses. Symptoms can include redness, itching, and swelling at the site of contact. It's important for those with known aluminum allergies to avoid products containing aluminum and to consult with a healthcare provider for proper diagnosis and management of their allergy.</p>

- Q: This question asks about the interaction between aluminum and electromagnetic radiation, specifically how aluminum influences or is affected by such radiation.

- <p>Aluminum has a high electrical conductivity and is a good reflector of electromagnetic radiation. It reflects a wide range of frequencies, including visible light, ultraviolet, and infrared radiation. Due to its reflective properties, aluminum is used in applications such as reflective coatings for insulation and mirrors. It also has the ability to shield against electromagnetic radiation, making it a common material in the construction of Faraday cages, which are used to block external electromagnetic fields. Aluminum's effect on electromagnetic radiation is primarily through reflection and shielding, rather than absorption or transmission.</p>

- Q: This question asks about the various uses of aluminum alloys within the construction industry.

- <p>Aluminum alloys are widely used in construction due to their strength, light weight, and corrosion resistance. Some applications include: 1) Structural framing for buildings and bridges, leveraging their high strength-to-weight ratio. 2) Window and door frames, benefiting from their durability and low maintenance. 3) Roofing materials, as they are lightweight and resistant to weathering. 4) Facade cladding, for aesthetic appeal and resistance to environmental damage. 5) Electrical wiring and conduits, due to their excellent electrical conductivity and safety. 6) Scaffolding, as they are lightweight and easy to assemble. 7) Solar panel frames, taking advantage of their lightweight and recyclable properties. These applications highlight aluminum alloys' versatility and importance in modern construction.</p>

- Q: Is it possible to utilize aluminum as a material for automotive construction?

- <p>Yes, aluminum is commonly used in cars. It is valued for its lightweight properties, which can improve fuel efficiency and reduce emissions. Aluminum is used in various parts of a vehicle, including engine components, body panels, and suspension systems. Its high strength-to-weight ratio and resistance to corrosion make it an ideal material for automotive applications.</p>

- Q: Is it possible to utilize aluminum in the creation of innovative electronic devices?

- <p>Yes, aluminum can be used to make new types of electronic devices. Aluminum is a lightweight, corrosion-resistant, and highly conductive material, making it ideal for various electronic components. It's commonly used in heat sinks, casings, and wiring due to its thermal and electrical conductivity. Additionally, aluminum's malleability allows it to be shaped into intricate parts, which can be beneficial for compact and innovative designs in electronics. Furthermore, its abundance and low cost make it an attractive material for manufacturing new electronic devices.</p>

- Q: Is it safe to use pure aluminum for baking or roasting food in a traditional oven or grill?

- <p>While pure aluminum is a common material in cookware, it's not recommended for direct use in baking or roasting food in a traditional oven or grill. Aluminum can react with acidic foods, potentially leaching aluminum into the food. Additionally, aluminum foil can burn and create a hazardous situation. For baking or roasting, it's safer to use materials specifically designed for these purposes, such as parchment paper, silicone baking mats, or oven-safe dishes.</p>

- Q: Describe the reaction of aluminum with acids and bases.

- <p>Aluminum reacts differently with acids and bases. With acids, aluminum undergoes a redox reaction where it loses electrons and forms Al^3+ ions. This reaction is exothermic and releases hydrogen gas. The general reaction with a non-oxidizing acid like hydrochloric acid is: 2Al + 6HCl 鈫?2AlCl鈧?+ 3H鈧? In the presence of a strong base, aluminum reacts with water to form aluminate ions and hydrogen gas, a process known as an alkaline hydrolysis. The reaction can be represented as: 2Al + 2OH鈦?+ 6H鈧侽 鈫?2Al(OH)鈧勨伝 + 3H鈧?</p>

- Q: Is it possible to enhance the efficiency of solar panels by utilizing aluminum?

- <p>Yes, aluminum can be used to improve the efficiency of solar panels. Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, which can help in dissipating heat and maintaining optimal operating temperatures for solar cells. It is also used in the manufacturing of solar panel frames, providing structural support while reducing the overall weight of the panels. Additionally, some research suggests that using aluminum in the backsheet of solar panels can enhance their durability and efficiency. However, the extent of efficiency improvement depends on various factors, including the specific design and manufacturing process of the solar panels.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum as a material in construction projects.

- <p>Aluminum in construction offers several advantages, including its lightweight nature, which reduces structural load and facilitates easier transportation and installation. It is also highly resistant to corrosion, making it ideal for outdoor applications and in areas with harsh weather conditions. Aluminum's recyclability contributes to sustainability, and it has a high strength-to-weight ratio, enhancing structural integrity. However, it has some disadvantages, such as being a poor conductor of heat, which may require additional insulation. It can also be more expensive than traditional materials like steel or concrete, and it dents easily, necessitating careful handling and maintenance.</p>

- Q: Explain the relationship between aluminum and electrum, if any.

- <p>Aluminum and electrum are two distinct metals with no direct relationship. Aluminum is a lightweight, silvery-white metal that is the most abundant metallic element in the Earth's crust. It is known for its corrosion resistance and is widely used in various industries. Electrum, on the other hand, is a naturally occurring alloy of gold and silver, valued for its unique properties and historical significance. While both metals are used in various applications, they are chemically and physically different and do not have a direct connection.</p>

Send your message to us

Aluminum Polyester Color Coated Coil Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords