Aluminum Pipes for Building Aluminum Profiles

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

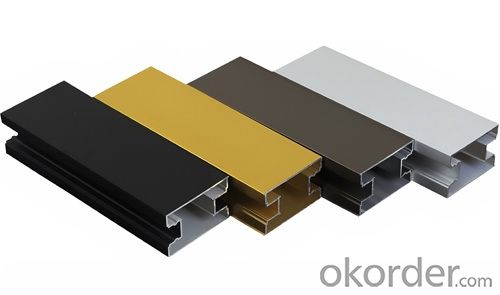

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Furniture;2. Drilling; 3. Bending; 4. Cutting; 5. Windows and doors;6.etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: There's a small hole in the aluminum tube on the air conditioner. Can I use it?

- If is refrigerant tube, a hole is impossible to run, the refrigerant had leaked out.If you want to continue to use air conditioning, must find a professional maintenance staff to pipe trap, re filling refrigerant can.

- Q: Please enlighten master formula of tube weight?

- Aluminium tube weight (kg) =0.00879 * wall thickness * (outside diameter wall thickness) * length (M), remaining mm

- Q: Are aluminum pipes compatible with different fittings and connectors?

- Aluminum pipes usually work well with a variety of fittings and connectors. Thanks to its versatility, aluminum can be easily manipulated through machining, welding, or threading to accommodate different types of fittings and connectors. This makes it convenient to join aluminum pipes with other components or systems, including valves, hoses, or other piping materials. Moreover, aluminum boasts outstanding resistance to corrosion, making it even more compatible with various fittings and connectors. It can endure exposure to different fluids or environments without deteriorating or reacting negatively. Nevertheless, it is crucial to use fittings and connectors specifically designed for aluminum pipes to guarantee a secure and leak-free connection.

- Q: Can the air conditioner low pressure pipe and high pressure pipe be expanded with aluminium pipe at the two ends?

- Yes, but the aluminum tube is easy to crack. Be very careful. I opened a shop maintenance for seven or eight years, only a few times with aluminum pipe to do the bell mouth, the problem is not, just be careful. Of course, it is recommended to use brass bell mouth, good toughness, not easy to crack.

- Q: Can aluminum pipes be used for transporting liquids?

- Yes, aluminum pipes can be used for transporting liquids. Aluminum pipes are commonly used in various industries for fluid transportation due to their excellent corrosion resistance and lightweight properties. They are particularly suitable for transporting non-corrosive liquids such as water, oils, and certain chemicals. Aluminum pipes are also easy to install and maintain, making them a cost-effective choice for liquid transportation systems. However, it is important to ensure compatibility between the liquid being transported and the aluminum material to avoid any chemical reactions or damage to the pipes.

- Q: Which kind of strength is good?No, at the moment I don't have any grades!

- In contrast, the cold tolerance capacity of the same specification tube is greater than that of the extruded pipe. Only cold drawing, the mold and its material requirements are very high, so cold drawn pipe prices slightly higher.

- Q: Can aluminum pipes be used for aerospace applications?

- Indeed, aerospace applications can make use of aluminum pipes. The aerospace industry favors aluminum owing to its unique blend of robustness, lightness, and resistance to corrosion. Aluminum pipes are frequently employed in the construction of aircraft components, including fuselages, wings, and landing gear, as well as in different systems such as fuel and hydraulic lines. Incorporating aluminum pipes enhances fuel efficiency and diminishes overall weight, which are pivotal considerations in aerospace designs. Furthermore, aluminum possesses the advantageous ability to be easily shaped and welded, rendering it a versatile option for aerospace purposes.

- Q: Are aluminum pipes suitable for portable water tanks?

- Yes, aluminum pipes are suitable for portable water tanks. Aluminum is a corrosion-resistant material, which makes it safe for transporting and storing portable water. Additionally, aluminum pipes are lightweight, durable, and can withstand high pressure, making them a practical choice for portable water tanks.

- Q: What are the advantages of using aluminum pipes?

- There are several advantages of using aluminum pipes, making them a popular choice in various industries and applications. Firstly, aluminum pipes are lightweight, which makes them easy to handle and transport. This characteristic is particularly beneficial in industries such as automotive and aerospace, where reducing weight is crucial for fuel efficiency and overall performance. Additionally, the lightweight nature of aluminum pipes makes them easier to install and requires less effort during maintenance or repairs. Secondly, aluminum pipes have excellent corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface, preventing it from rusting or deteriorating in harsh environments. This resistance to corrosion makes aluminum pipes ideal for applications where they are exposed to moisture, chemicals, or extreme temperatures. They are commonly used in plumbing, HVAC systems, and marine applications. Another advantage of aluminum pipes is their high thermal conductivity. Aluminum is an excellent conductor of heat, allowing for efficient heat transfer. This characteristic makes aluminum pipes suitable for applications where heat dissipation is critical, such as heat exchangers and radiators. Furthermore, aluminum pipes are highly durable and have a long lifespan. They have a high strength-to-weight ratio, meaning they are strong enough to withstand pressure and stress while being lightweight. This durability makes them a cost-effective choice as they require fewer replacements or repairs over time. Lastly, aluminum pipes are environmentally friendly. Aluminum is a highly recyclable material, and recycling it requires only a fraction of the energy needed to produce new aluminum. Choosing aluminum pipes contributes to sustainable practices and reduces the overall carbon footprint. In conclusion, the advantages of using aluminum pipes include their lightweight nature, corrosion resistance, high thermal conductivity, durability, and environmental friendliness. These qualities make aluminum pipes a versatile and reliable choice for various industries and applications.

- Q: What is the tensile strength of aluminum pipes?

- The tensile strength of aluminum pipes can vary depending on the specific grade and alloy of aluminum used. However, on average, aluminum pipes have a tensile strength ranging from 30,000 to 45,000 pounds per square inch (psi). It is important to note that the tensile strength of aluminum pipes can be enhanced through various processes such as heat treatment or alloying with other metals. Additionally, the diameter and thickness of the pipe can also affect its tensile strength. Therefore, it is advisable to consult the manufacturer's specifications or conduct specific material testing to determine the exact tensile strength of a particular aluminum pipe.

Send your message to us

Aluminum Pipes for Building Aluminum Profiles

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords