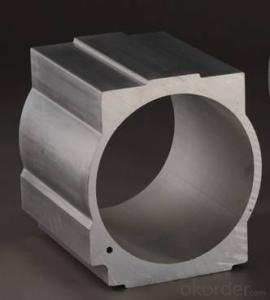

Aluminum Pipes - AA6060 Aluminium Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1 Specifications of Aluminum Profiles 6061-T5

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles 6063-T5

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

- Q: The air conditioner is broken in the middle of the aluminum tube. How can I weld it?

- There are two kinds of welding methods for aluminum pipe.Method: gas, liquefied gas welding gun with WE-Q303 low temperature aluminum wire.Method two: AC argon arc welding, argon arc welding with aluminum argon arc welding machine.

- Q: What are the common insulation materials used for aluminum pipes?

- The common insulation materials used for aluminum pipes are fiberglass, foam insulation, and rubber insulation.

- Q: How to repair the surface defects of aluminum pipe

- Method: to hand percussion pits with oxyacetylene flame annealing, after cooling, use hand hammer into the aluminum oblate tube, estimated knocking position try to knock, knock point and observe from the outside, adjusted and confirmed the knock point after the afterburner struck, until the elimination of pits. If it is difficult to strike in the middle, it is expected to be hardened by metal hammering. It must be reheated and annealed again, and then continue after cooling. The method is generally applicable to the repair of the larger diameter aluminum tube and the hand length of the pit. Not suitable for trimming of flattening defects

- Q: How is the seamless pipe or tube seam identification for enlighten heroes?

- Generally speaking with tubes inside you can see the weld line or spiral line, it is the high frequency welding seam. Seamless aluminum pipe wall thickness is relatively thick, there is no welding seam inside.

- Q: What are the different pressure testing methods for aluminum pipes?

- Some of the different pressure testing methods for aluminum pipes include hydrostatic testing, pneumatic testing, and ultrasonic testing. Hydrostatic testing involves filling the pipe with water and increasing the pressure to check for leaks or weaknesses. Pneumatic testing, on the other hand, uses compressed air to assess the pipe's ability to hold pressure without any leaks. Ultrasonic testing utilizes sound waves to detect any defects or flaws in the aluminum pipe. These different methods help ensure the integrity and safety of aluminum pipes in various applications.

- Q: How can the plastic parts be fastened in the aluminum tube and the plastic parts are not drawn out?

- This habit is not defined, as engineers, all digital, not with the concept of size, good or bad, precision, and other description of engineering and technical problems.

- Q: Please help to analyze the cause of the formation Fifty1070 aluminum rods are made of aluminum tubes from extrusion units. The process is: extrusion, melting - the mold passes through (the formation of aluminum tubes) - tap water cooling - closing - nitrogen charging and pressure maintaining. Therefore, the internal pipeline is nitrogen protection, and after a period of time, the pipeline will appear white powder, affecting resistance welding, welding is not firm, easy to fall off and leak.

- AskIn fact, we suspect that it is alumina, but I don't know how to avoid it.Chasing the answerThere are two best ways:1. Keep the environment air dry.2. Apply anti oxidation coating for pipes.Or third: strengthen daily cleaning.

- Q: Are aluminum pipes resistant to saltwater corrosion?

- Yes, aluminum pipes are generally resistant to saltwater corrosion. Aluminum is known for its excellent corrosion resistance, including resistance to saltwater. It forms a thin, transparent oxide layer on its surface when exposed to oxygen, which acts as a protective barrier against corrosion. This oxide layer helps to prevent the metal from reacting with saltwater, thus making aluminum pipes highly resistant to saltwater corrosion. However, it is important to note that prolonged exposure to saltwater can still lead to some degree of corrosion over time, but compared to other metals, aluminum is considered to be one of the most corrosion-resistant materials for saltwater applications.

- Q: Are aluminum pipes affected by exposure to fire or flames?

- Yes, aluminum pipes are affected by exposure to fire or flames. Aluminum is a non-combustible material, meaning it does not catch fire or burn on its own. However, when exposed to high temperatures, aluminum pipes can still be affected by the intense heat. Aluminum has a low melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), so it can start to soften and deform under the extreme heat of a fire. This can lead to structural damage and compromise the integrity of the pipes, potentially causing leaks or failure. Therefore, it is important to take precautions and protect aluminum pipes from direct exposure to fire or flames to ensure their longevity and functionality.

- Q: Can aluminum pipes be used for conveyor rollers?

- Indeed, aluminum pipes have the capability to serve as conveyor rollers. Aluminum, being a material that is both lightweight and durable, presents numerous benefits for conveyor systems. Its resistance to corrosion renders it appropriate for usage in a range of environments, including those with exposure to moisture or chemicals. Moreover, aluminum pipes possess a notable strength-to-weight ratio, enabling them to endure hefty loads while remaining light in weight. Furthermore, aluminum proves to be effortless to manipulate and can be tailored to fulfill specific requirements such as size, shape, and length. Consequently, aluminum pipes emerge as a fitting selection for conveyor rollers, providing a dependable and efficient solution for handling materials.

Send your message to us

Aluminum Pipes - AA6060 Aluminium Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords