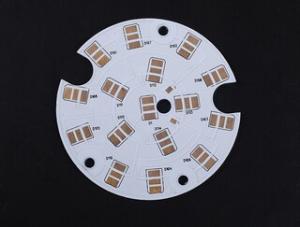

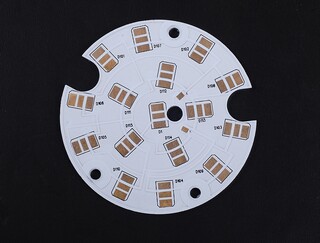

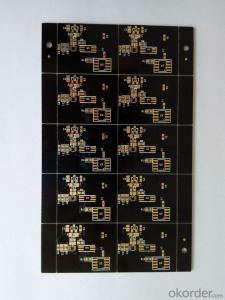

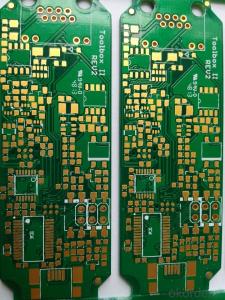

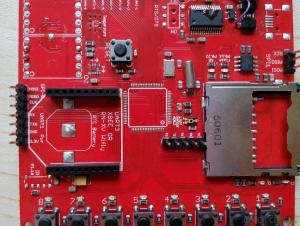

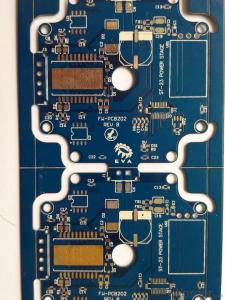

Aluminum PCB OEM

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

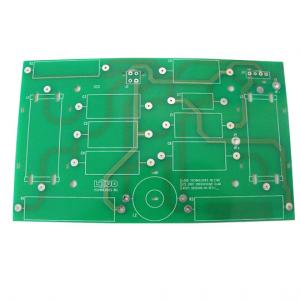

Rigid PCB1. Low cost, Minimum cost for 3 prototypes PCB is $80 only.

2. Short lead time.

3. PCB RoHS compliant.

4. OEM

Details for your check:

Layers | 1-10 |

Board Material | FR4, CEM-1,CEM-3 |

Board Thickness | 0.2mm~3.2mm |

Camber | D≤ 0.075mm (Double Side) D≤ 1% (Multilayer) |

Impendence Tolerance | ±7% |

PTH Tolerance

| D>5.0 ±0.076mm 0.3<D≤5.0 ±0.05mm D≤0.3 ±0.08mm |

Min. Finished Hole Size | 0.2mmm |

Hole Copper Thickness | ≥20um |

Min.Track Width | 0.10mm |

Min.Track Spacing | 0.10mm |

Profile Size Tolerance | ±0.1mm |

Profile | Milling, Moulding, V-cut,Chanfer |

Coating | HASL, Lead Free HASL, Enig/Immersion Gold, OSP |

Solder Mask Color | Green, Blue, Black, White, Red |

Technology | Block, BGA, Peelable, Carbon ink |

Legend Color | White |

- Q: What is the tolerance range of the size of the copper foil of the PCB board?

- Copper clad laminate national standard: GB4723~4725 "printed circuit copper clad laminate", as a result of years of revision, the standard thickness of the copper clad plate, single point deviation requirements are relatively loose.

- Q: Several kinds of circuit boards

- According to the different resin adhesive used in the classification, the common paper based CCI. There are: phenolic resin (XPc, XxxPC, FR 1, FR 2, etc.), epoxy resin (FE a 3), polyester resin and other types. Glass cloth CCL common epoxy resin (FR 4, FR 5), it is the most widely used type of glass fiber cloth at.

- Q: What is the LPC inspection standard for PCB?

- The IPC standard for printed circuit boards is IPC-600, which is a general specification;

- Q: The circuit board with strong is how to do?

- The reinforcing plate itself is a kind of FR-4 material or metal material, which is machined into the desired shape.

- Q: How to enlarge the size of the existing PCB board?

- It is impossible to enlarge the size of the existing PCB board. However, the pure amplification of PCB is still possible, because the components are not enlarged, so the PCB board needs to re wiring. Just change the size of the wiring layer.

- Q: What are some of the PCB substrate materials? How to classify?

- There are many kinds of classification methods of copper clad laminate. According to the general board reinforced with different materials can be divided into: paper base, glass fiber cloth, composite base (CEM Series), build up multilayer plate base and special material (ceramic, metal core based) five categories. According to the different resin adhesive used in the classification, the common paper based CCI. There are: phenolic resin (XPc, XxxPC, FR 1, FR 2, etc.), epoxy resin (FE a 3), polyester resin and other types. Glass cloth CCL common epoxy resin (FR 4, FR 5), it is the most widely used type of glass fiber cloth at.

- Q: What's the difference between PCB and FBC?

- The PCB circuit board, is specialized in the production of circuit boards.

- Q: The prospect of flexible circuit board

- In the next few years, smaller, more complex and more expensive assembly of flexible circuits will require more novel methods of assembly, and the need to increase the hybrid flexible circuit. The challenge for the flexible circuit industry is to keep pace with the computer, telecommunications, consumer demand and active market. In addition, the flexible circuit will play an important role in the lead-free operation.

- Q: PCB carbon oil plate is what kind of technology?

- PCB carbon oil board to print "E" carbon oil area, it is best to draw in the 99SE inside (also can be drawn in other software), you can not draw, but you want to solder the window in 99SE to do a good job

- Q: What is a circuit board milling machine? And numerical control which is easier?

- But if the processing circuit board substrate, the accuracy can be up to standard, it is very cost-effective, which itself has a simple numerical control.

Send your message to us

Aluminum PCB OEM

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches