OEM China manufacture Aluminum Die casting parts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

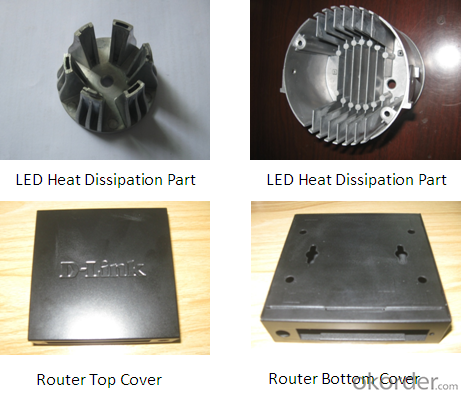

OEM China manufacture Aluminum Die casting parts

Details

*Service: Opening mold、die casting、trimming、sanding、deburr、drilling、tapping、polishing、chromation、painting/powder、screen print and packing, customized

*Material Capabilities: Aluminum alloy, zinc and so on

*Place of Origin: Guangdong,

*Material: SGS Test Report

*Surface Finish: Anodize& Sandblasting

*MOQ: 1-10PCS

*Annual: 5,000,000pcs

*Inspection: 100% inspection

*Lead Time: 5-18 days

*Payment: T/T, Western Union

Packaging & Delivery

Packing details: Blister packing inside and carton outside

Delivery time: 5-20 days

Specifications

1. Material Types: ADC12, A380, 3#, AlSi12; Zamak 1 & 3 & 5,ZZnA14Y, 22nA14Cu1Y (zinc)

2. Factory price

3. Process: Customer provides drawing, we will open mold、die casting、trimming、sanding、deburr、drilling、tapping、

polishing、chromation、painting/powder、 screen print and packing

Tooling Design and Mold Flow Simulation Design Aids Tool Like Die Casting…

Conventional Precision Die Casting

Tooling Fabrication

Trimming & De-Gating

De-Burring & Polish, Degreasing, Ultrasonic Washing

Sand Belt Grinding & Fine Polishing

Bench Drilling & Tapping

CNC Machining

Chromation, Plating and E-Coating

Passivation, Powder and Oil Painting & Silk-Screening

Sub-Assembly

OEM

Welcome to see pictures for OEM China manufacture Aluminum Die casting parts:

- Q: How many kinds of hardware are there in this industry?

- Many kinds of hardware products, different specifications of hardware products, but in the Home Furnishing decoration also plays an irreplaceable role, choose a good hardware accessories can make a lot of decoration materials use more safe and convenient. At present, there are more than ten kinds of hardware products in the materials market. 1, lock (1) is arranged outside the lock (2) lock (3) lock the drawer (4) ball type door lock (5) glass window lock electronic lock (6) (7) (8) chain lock anti-theft lock (9) lock the bathroom (10) (11) number lock padlock (12) the lock (13) lock core 2, handle class (1) drawer pull hand (2) cabinet (3) glass door handle 3, doors and windows hardware (1) glass hinge: hinge, hinge, hinge corner bearings (copper and steel), pipe hinge hinge (2) (3): drawer track rail, sliding door track, hanging wheel, glass block

- Q: What are the commonly used hardware materials? What are their respective properties?

- Hardware is a kind of building materials industry, including construction hardware, mechanical hardware, spraying equipment, kitchen facilities, bathroom facilities and hardware fittings.The traditional hardware refers to hardware, refers to iron, steel, aluminum and other metal, through forging, calendering, cutting, and so on physical processing made from various metal devices. There are many kinds of hardware products, and the specifications are not the same. They occupy an important position in furniture decoration.Big hardware includes steel plate, steel, flat iron, steel bar, universal channel iron, I-iron and various types of hardware, building hardware, tin, lock nails, wire, steel wire, steel wire cutting, home hardware, tools etc.. On the nature and use of hardware, iron and steel materials, non ferrous metal materials, machinery parts, transmission equipment, auxiliary tools, working tools, construction hardware, household hardware and other eight categories are to be considered.

- Q: How to inquire about the price of hardware products? How much is the gross profit of hardware products? Thank you

- Gross profit does not know, but you can go to the hardware product supply, purchase price and so on to make some understanding, and then make a decision

- Q: What kind of goods do you need to open a hardware store?

- There are a lot of ah, tools, parts, screws, bearings, lighting, electrical materials, water cooler, there are some other configurations, such as titanium alloy frame. If you want to shop, you can go to shentop Hotel Web browsing, there are many types of him, should be for you.

- Q: What kind of hardware installation is there in order of home decoration?

- If the door (door and door): first hinge positioning (or repair groove), temporary installation - positioning lock, remove the lock - processing and installation after formal installation of the door, and installed in the positioning door -- etc.

- Q: What are the hardware parts used in the decoration?

- Decoration hardware used many, hardware accessories a wide range, wide range of applications,

- Q: What does hardware include?

- Big hardware refers to steel plate, steel bar, flat iron, universal angle iron, trough iron, I-shaped iron and various types of steel materials;

- Q: How to maintain the hardware?

- Always use soft cotton or sponge with neutral soap water to wipe the surface of the faucet, to avoid water containing trace amounts of carbonic acid, forming scale, and corrosion on the surface of the faucet

- Q: What kinds of hardware fittings can be divided into?

- Hardware accessories can be classified according to standard and non-standard parts. This classification is general, but the general classification is like this, and there are different hardware used in different industries, there are different categories.

- Q: What does a hardware factory do?.

- Hardware: traditional hardware, also known as "hardware"". Of five metals: gold, silver, copper, iron, and tin. By artificial processing, you can make knives, swords and other art or metal devices. The hardware of modern society is more extensive, such as hardware tools, hardware parts, daily hardware, construction hardware and security products.

Send your message to us

OEM China manufacture Aluminum Die casting parts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches