Aluminum magnesium manganese system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

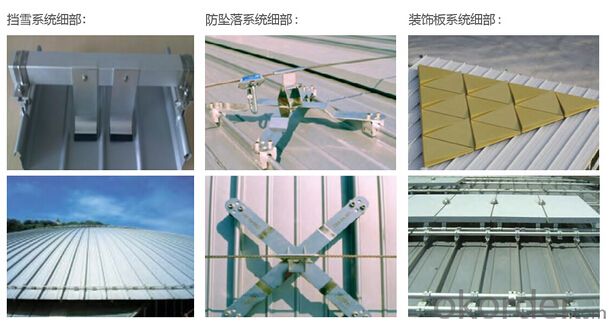

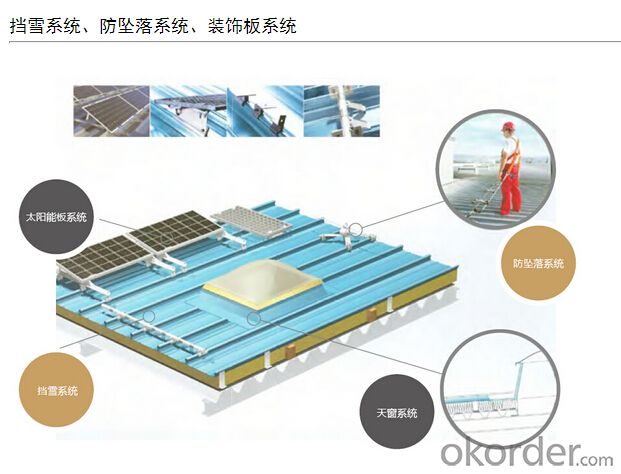

System introduction:

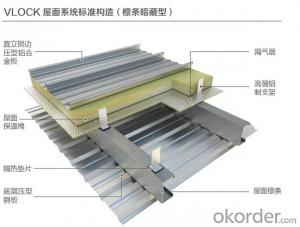

DW Al-Mg-Mn board is the alloy mixed by metallic aluminum, metallic magnesium and metallic manganese. The metallic aluminum, magnesium, manganese alloy is widely used as the material of metal roof for which the building design service life is more than 50 years as it has advantages such as moderate structure strength, weather-proof, waterlogging tolerance and easy be bent, welded and processed, etc.

Connection way:

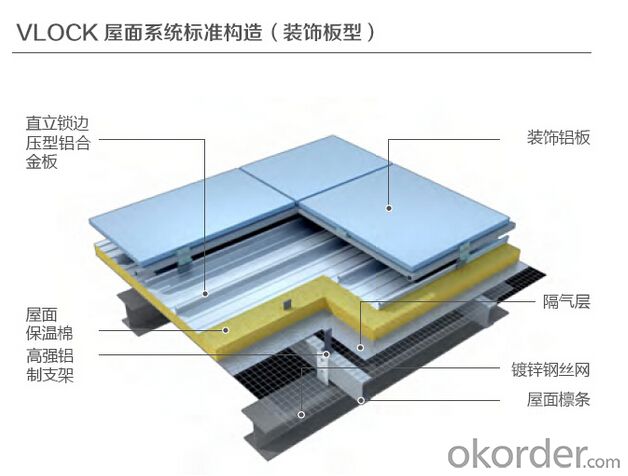

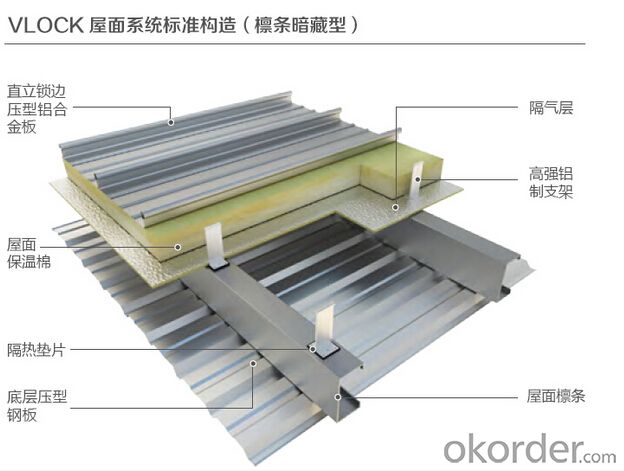

Processing of Al-Mg-Mn roof board→ measuring and setting out→ installation and calibration of support at joint → installation of purline → installation of galvanized profiled punched steel bottom board → installation of lined purline and its support → installation of gutter →aluminum alloy T support → laying of non-woven fabrics for installation → installation of acoustic wool → installation of steel wire mesh → laying of vapor barrier → installation of glass insulation cotton → installation of aluminum alloy roof board → installation of skylight → installation of sunshine board → processing of roof-crossing rods, expansion joint and other joints

Applicable project:

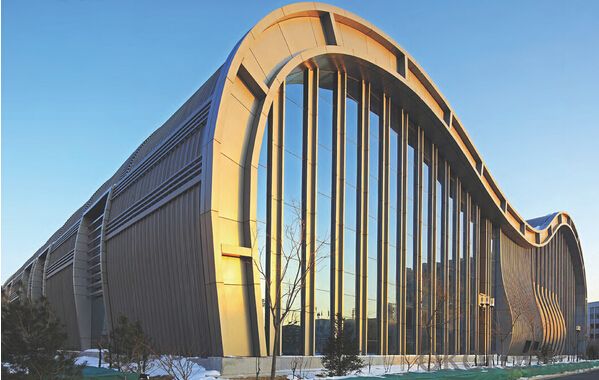

It is applicable to spherical, arc and peculiar roofs with small radian and radius, and complicated structure such as airport, stadium, conference center, business center, superior villa, convention center and industrial workshop, etc, especially applicable to large public engineering for which the roof has steel support, and also peculiar and complicated structure.

- Q: I am looking for woodworking furniture, what kind of wood is not easy to deformation, wood prices? Thank you!

- Do not listen to their blind gully, of course, with their own choice of economic materials like Qiutong is the best choice

- Q: What are the PCBs

- 1) Flame Retardant Copper Foil Epoxy E Glass Fiber Cloth Laminate and Its Adhesive Sheet Material. IPC4101 detailed specification number 21; Tg ≥ 100 ℃; 2) Flame Retardant Copper Foil Modified or Unmodified Epoxy E Fiberglass Laminated Laminate and Bonding Sheet Material. IPC4101 detailed specification number 24; Tg 150 ° C to 200 ° C; 3) Flame Retardant Copper Foil Epoxy / PPO Glass Cloth Laminate and Its Adhesive Sheet Material. IPC4101 detailed specification number 25; Tg 150 ° C to 200 ° C; 4) flame retardant copper clad modified or unmodified epoxy glass cloth laminate and its adhesive sheet material. IPC4101 detailed specification number 26; Tg 170 ℃ ~ 220 ℃; 5) Flame Retardant Copper Foil Epoxy E Glass Cloth Laminate (for Catalytic Addition). IPC4101 detailed specification number 82; Tg N / A;

- Q: PVC sheet size how much the largest

- The main plate is the width, mainly 1.2 meters and 1.5 meters before the main, and now the widest can reach 2.8 or even 3 meters. As for the length is to see what you need, it is continuous production, according to your request cut.

- Q: Because the family has children, do not worry ah ~ ~ ah! Is it possible to detect it?

- As long as the wood furniture are formaldehyde. Indoor pollution six categories: formaldehyde, benzene, toluene, xylene, ammonia, TVOC Families with children must be treated! Liver and kidney function is still developing, toxins into the can not be completely discharged ..... 90% of children with leukemia is caused by decoration pollution!

- Q: Round round plate, environmental protection plate top ten brands

- Now the decoration is environmentally friendly sheet, the top ten brands are: round and round, Fuqing, Moganshan, Millennium boat, bunny, etc.

- Q: Will the 2017 plate 10 brand quality how?

- Ranked by quality, the New Zealand Pavilion is a well-deserved first. New Zealand Chilean plate benefited from New Zealand's unique island climate, and in the case of the ever-decreasing natural forests in the world, New Zealand Wood has grown well as a sustainable renewable resource. Zhige plate selection of trunk high, light color, solid wood, very suitable for furniture manufacturing and a variety of decorative wood applications.

- Q: How to color the plate after carving

- When the font is colored, the first pigment (such as gold powder, silver powder, etc.), with ordinary office glue mixed mix, drop a few drops of diesel, pay attention not to be too thin, with the mud of the kind of sand sand wall can be almost , And then placed on the carved panel, with a thick plastic sheet, (the best use of silk screen with the kind of scraper), gently scraping past, the pigment will stay in the concave font, In the outside of the paint with a soft damp cloth can be wiped, and some also use advertising pigments instead of color.

- Q: Vientiane and snowboard plate which is better

- There is no hesitation to choose the big brands: Xue Ling plate friends. The The

- Q: Home to decorate, and ready to ask the carpenter to play furniture, but do not know what plate on the plate is good, small pollution and moisture effect is good, but also ask the bathroom cabinet if you buy plate to play what plate is good? Please have experienced friends to give me guidance, thank you!

- Wardrobe or finger board is good, environmental protection, with less formaldehyde to do live to see also comfortable! Bathroom cabinets also use this plate to brush the varnish after the waterproof is particularly good, and this board does not have a plate can have a feeling of logs!

- Q: PCB board material how to identify

- The so-called FR4 and CEM refers to the difference between the resin and the filler, regardless of the copper foil. You can look at the PCB drawings or ask the supplier on the line! CEM is a bit brittle and easy to sack

Send your message to us

Aluminum magnesium manganese system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords