Aluminum Louver Blade Profiles Arizona - Aluminium Profile Manufacturer Offer Different Types for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Profile Manufacturer Offer Different Type for Sale

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

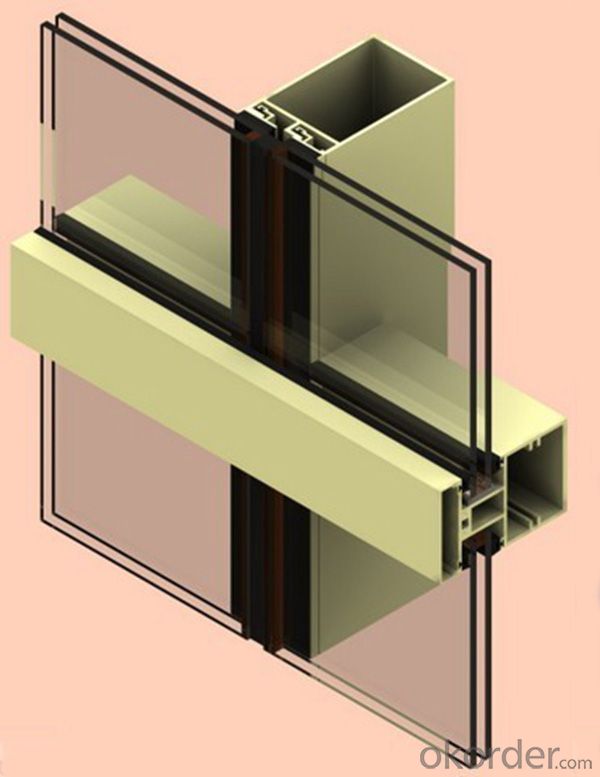

2. Application of Aluminium Profile Manufacturer Offer Different Type for Sale

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminium Profile Manufacturer Offer Different Type for Sale

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

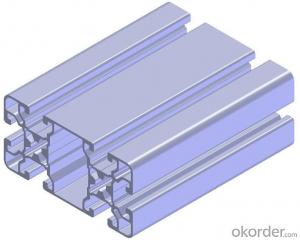

5. Image of Aluminium Profile Manufacturer Offer Different Type for Sale

6. Package and shipping of Aluminium Profile Manufacturer Offer Different Type for Sale

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: This question asks for a list of various uses of aluminum profiles within the construction industry.

- <p>Aluminum profiles have a wide range of applications in the construction industry due to their strength, durability, and lightweight properties. They are used in window and door frames for their resistance to corrosion and ease of maintenance. They are also employed in curtain walls, which are the outer coverings of buildings, providing both aesthetic appeal and structural integrity. Aluminum profiles are utilized in the construction of scaffolding for their high strength-to-weight ratio, ensuring safety and stability. Additionally, they are used in the manufacturing of modular buildings and prefabricated structures due to their ease of assembly and disassembly. Other applications include roofing systems, flooring structures, and as support beams in various construction projects.</p>

- Q: What are the methods to reduce waste from aluminum profiles in construction?

- <p>To minimize waste generated from using aluminum profiles in building construction, consider the following strategies: 1) Accurate planning and design to reduce offcuts. 2) Utilize modular designs to maximize material usage. 3) Implement recycling programs to repurpose leftover profiles. 4) Opt for suppliers that provide aluminum profiles cut to exact specifications. 5) Educate workers on proper handling and waste reduction techniques. 6) Use digital tools for precise cutting to minimize material waste. 7) Encourage the use of aluminum due to its high recyclability and low energy consumption in the recycling process.</p>

- Q: Can aluminum profiles be used for signage or display purposes?

- Certainly, signage or display purposes can definitely utilize aluminum profiles. Aluminum, a versatile and durable material, finds wide usage in several industries, including signage and display. By providing a robust framework, aluminum profiles ensure stability and longevity for signs and displays. Due to its lightweight nature, aluminum is effortless to handle and install, thus making it a favored option for both outdoor signage and indoor displays. Additionally, aluminum profiles can be easily customized and fabricated into diverse shapes and sizes, thereby allowing for creative and flexible designs. In addition, aluminum profiles possess excellent resistance against corrosion, guaranteeing the signage or display's good condition even in outdoor or high-moisture environments. This quality renders them suitable for a broad range of applications, such as storefront signs, directional signs, trade show displays, exhibition booths, and many others. Moreover, aluminum profiles can receive powder coating or anodization to impart an ornamental finish, thereby enhancing the visual appeal of the signage or display. This offers branding and customization options, thus making aluminum profiles an excellent choice for businesses aiming to showcase their brand identity. Overall, aluminum profiles serve as a dependable and versatile choice for signage or display purposes. They possess strength, durability, design flexibility, and corrosion resistance, which makes them suitable for various applications across different industries.

- Q: Household aluminum profiles, which brand of cost-effective? Recommend!

- Cost performance is better, in our Nanshan factory is called a good fight,

- Q: How much is the 60 series aluminum frame bridge standard size, how much is the size of the fan

- [60] galuminium Qianjin aluminum series insulating aluminum window size 60x53.5, window size 67.8x68.6.

- Q: Can aluminum profiles be used for agricultural or farming applications?

- Yes, aluminum profiles can indeed be used for agricultural or farming applications. Aluminum profiles offer several advantages that make them suitable for these applications. Firstly, aluminum is lightweight, which makes it easy to transport and install. This is particularly beneficial in agricultural settings where mobility and flexibility are essential. Additionally, aluminum is highly resistant to corrosion, making it ideal for use in harsh environments such as farms where exposure to moisture, chemicals, and fertilizers is common. Its resistance to rust ensures durability and longevity, reducing the need for frequent replacements. Furthermore, aluminum profiles can be easily customized and fabricated to meet specific requirements. This flexibility allows for the creation of structures like greenhouse frames, support beams, shelving systems, and other components needed in agricultural operations. Moreover, aluminum profiles are non-toxic and do not release any harmful substances into the surrounding environment. This makes them safe for use in farming applications, where the health and well-being of animals and crops are of utmost importance. Lastly, aluminum is a sustainable material that can be recycled indefinitely, reducing its environmental impact. This aligns with the growing focus on sustainability in agriculture. In conclusion, due to their lightweight nature, corrosion resistance, adaptability, safety, and sustainability, aluminum profiles are indeed suitable for various agricultural and farming applications.

- Q: Are there any differences between aluminum alloy and aluminum alloy?

- Aluminum alloy refers to the material, aluminum alloy refers to the productIt's like the difference between gold and gold

- Q: What are the methods to protect aluminum profiles from corrosion during the installation and usage phases?

- <p>To prevent corrosion of aluminum profiles during installation and use, follow these steps: 1. Choose high-quality aluminum profiles with proper alloy composition that resists corrosion. 2. Ensure the surface is clean and free from contaminants before installation. 3. Apply a protective coating such as a clear anodized finish, powder coating, or paint to the aluminum surface. 4. Avoid contact with corrosive substances like saltwater or chemicals. 5. Regularly inspect and clean the profiles to remove dirt and debris that can lead to corrosion. 6. Use stainless steel fasteners and avoid dissimilar metal contact, as it can accelerate corrosion. 7. Maintain a dry environment to prevent moisture-induced corrosion. By following these practices, you can significantly reduce the risk of corrosion and prolong the lifespan of aluminum profiles.</p>

- Q: What are the different machining options available for aluminum profiles?

- When it comes to aluminum profiles, there are various machining options available. The choice of technique depends on the desired outcome and the specific requirements of the project. One widely used technique is milling. It involves using a rotating cutter to remove material from the workpiece, resulting in complex shapes and features like slots, pockets, and contours. Another option is drilling, which is used to create holes in the aluminum profiles. This can be done manually or using CNC machines for precision and efficiency. Turning is a process where a single-point cutting tool is used to remove material from a rotating workpiece. It is commonly used for cylindrical or symmetrical profiles, enabling the creation of features like threads, grooves, and chamfers. For reshaping aluminum profiles, bending is the go-to process. By applying force, the profiles can be bent into the desired shape, making it ideal for architectural or structural purposes. If holes or cutouts are needed, punching is the way to go. A punch and die set are used to create openings for fasteners, connectors, or other components. Sawing, on the other hand, involves using a rotating blade to cut through the profiles. This technique is commonly used to achieve specific lengths or to separate profiles into smaller sections. Grinding is a process that utilizes an abrasive wheel to remove material and achieve surface finishing, deburring, or tight tolerances on the profile's dimensions. Each machining option has its own advantages and limitations. Factors such as the complexity of the desired shape, required precision, and material properties of the profiles should be carefully considered to determine the most suitable option for a given project.

- Q: Where is the exact location? TwentyBecause I was doing aluminum sales, want to go to the market!Where is the specific market aluminum sales, as long as there is, I have to go around! Say where it is! For example, what area, what road, how many?! Since I went to Chengdu for the first time, please tell me more about it. Thank you!

- 3rd Ring Rd Sichuan Shaanxi Home Furnishing District 6 Fujimori Mi Avenue Interchange panda is full profile, near the panda road hole profile market two large star market material wholesale. The variety is complete. The interchange in the North Sanhuan.

Send your message to us

Aluminum Louver Blade Profiles Arizona - Aluminium Profile Manufacturer Offer Different Types for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords