Aluminum Frame Formwork with Outstanding Performances

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

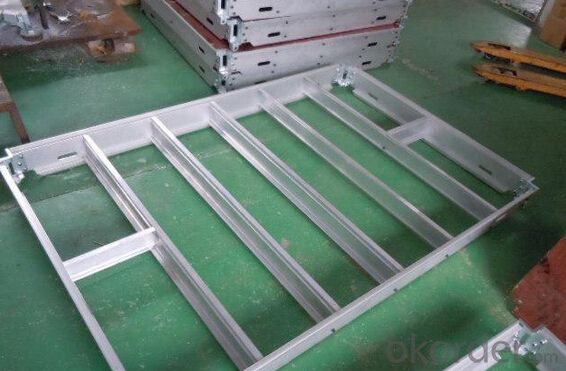

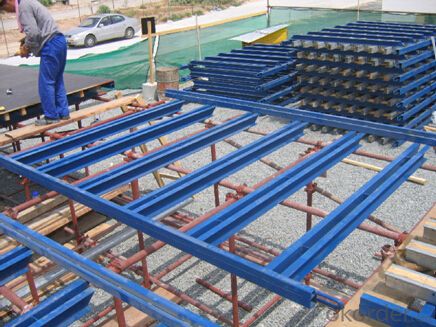

1. Structure of Aluminum-Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The board ends are protected either by metal plates called hoop irons or sometimes nail plates, which often have the company name stamped into them. Timber scaffold boards in the UK should comply with the requirements of BS 2482. As well as timber, steel or aluminum decking is used, as well as laminate boards. Additionally, overloading of scaffolding is a frequent cause of major scaffold failure.

2. Main Features of Aluminum-Frame Formwork

High standardized system.

Easy connection with adjustable steel clamp.

Convenient and fast corner formwork.

Flexible to assemble and application.

3.Aluminum-Frame Formwork Images

4. Aluminum-Frame Formwork Specification

The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

The adjustable steel clamp is convenient to use, and can hold tightly.

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

5. FAQ OF Aluminum-Frame Formwork

1) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

Aluminum-Frame Formwork cost can be refund after order is confirmed.

If the products are not based on the requirements, there will be the relevant compensations made for you.

2) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and

we are VIP of these express.

Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our

customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How does the vertical template at the suspension stand?

- The vertical degree of the wall is less than 5m vertical height of the allowable deviation is <= 6mm, when the wall height is greater than 5m vertical tolerance is allowed to <= 8mm

Send your message to us

Aluminum Frame Formwork with Outstanding Performances

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords