Aluminum Foil Faraday Cage Wholesale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specification of Aluminum Foil, Aluminum Foils, Aluminum Foil-paper from China:

1.Advantages of our Hot Rolled Checkered Steel Plate:

a) The unfairness of our checkered steel sheet must be less than 10mm each meter

b) The surface of our hot rolled checkered steel plate is free from bubble, scab, crack, fold, edge delamination and so on.

c) The height of our hot rolled checkered steel plate will be maintained between 0.2~0.3 times to thickness of steel substrate, but more than 0.5mm at least.

Applications of Aluminum Foil, Aluminum Foils, Aluminum Foil-paper from China:

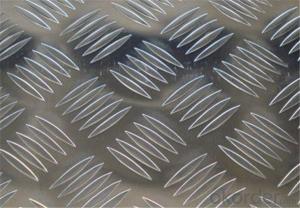

1.Definition: The hot rolled steel sheet with raised pattern on surface. The raised pattern could be shaped as rhombus,bean or pea. There is not only one kind of pattern on the checkered steel sheet, but also a complex of two or more than two kinds of pattern on surface of one checkered steel sheet. It also could be called as grid steel sheet.

2.Character: The Hot Rolled Checkered Steel Plate possesses a variet of advantages, such as beauty in appearance,skip resistance and saving steel material.Generally speaking,in order to test the mechanical property or the quality of hot rolled checkered steel sheet, the shaping rate and the pattern height should be tested primarily.

3. In conclusion, the hot rolled checkered steel plate can usually be used in the industry of ship-building,boiler,automobil,tractor,train- building and architecture. In details, there are many demands for hot rolled checkered steel plate to make floor,ladder at workshop,work frame pedal,ship deck,car floor and so on.

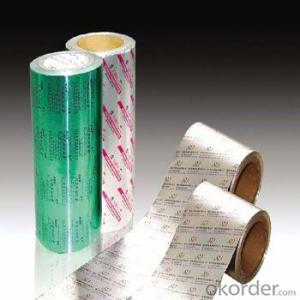

Package & Delivery of Aluminum Foil, Aluminum Foils, Aluminum Foil-paper from China:

1. The items to be prepared for packing include: narrow steel strip, crude steel belt or edge angle steel, kraft paper or galvanized sheet.

2. The hot rolled checkered steel plate should be wrapped with kraft paper or galvanized sheet ouside, and it should be bundled with narrow steel strip, three or two narrow steel strip in longitudinal direction,and the other three or two strips in transverse direction. Furthermore, in order to fix the hot rolled checkered steel plate and avoid the strip at edge shall be broken, the crude steel belt cut into square should be put under the narrow steel strip on the edge. Of course, the hot rolled checkered steel plate could be bundled without kraft paper or galvanized sheet. It depends on customer’s requirement.

3. In consideration of the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4. All in all, we could do in accordance with customer's request.

Production Flow of Aluminum Foil, Aluminum Foils, Aluminum Foil-paper from China:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Any ideas for good and easy things to cook while camping?

- water rocket made by bottles

- Q: Domestic aluminium foil for food use is 15 × 10–6 m thickIn my local supermarket, a roll of foil measuring 10 m by 0.3 m costs ?1.65.Calculate the cost per tonne of the foil as purchased in the supermarket.Account for any difference between this cost and the raw material cost of?1000 per tonne.The density of aluminium is 2700 kg m–3.Help please.Thanks.

- viscose is rayon it is treated same as cotton

- Q: cuz my oven doesn't work i wanted to try that so i got a piece of foil and wrapped the corn dogg with the foil then i heated up the pan thingy were you would heat up tortillas and like can you get like cancer of the foil like would it be dangerous to eat the corn dogg ???

- yesI cook with aluminum foil directly in flames, you can use foil on a pan, in the oven for baking, broiling, grilling, or like I said directly on the coalsYou probably don't want to smoke out of it, lol

- Q: I bought 2 pre-hung exterior doors for my houseThe back door turned out to be a project because the outside stoop (concrete) was built into the the door wayThis posed a problem because the sash that was already there (oak) was my only option rather the using the nice aluminum one already built into the door, I had to cut the frame of my door down about 3/4quot;Then I had to rip the existing oak sash down to about 1/2-2/3 it's original thicknessThe door works fine but I will have to do this to my front door too because it too has the concrete built in stoopSo what I would like to do is use the method I've used in the past to fit a pre-hung interior door into a existing open that is slightly shorter; and that is to cut the whole thing down (frame and door)But can I do this with my aluminum door, what kind of saw/blade would i use? I know I can remove the sash then reinstallI'd hate to do a hack job but want to use the sash that comes with it.Any suggestions?

- I'm guessing your door is not aluminum, it's steelThey don't use aluminum for entry doors because it's too softThere are several ways to cut a steel doorYour best bet is to use a jigsaw with a fine metal bladeAs long as you keep the speed relatively slow, your blade should stay squareIf necessary, cut again from the other side of the door to straighten that edgeYou can clean the cut up with a fileI wouldn't recommend using a circular saw, as the other posters statedAs the blade turns, it will tear out the top surface of the door, leaving a mess to clean upHope this helps.

- Q: life saver holes? can you still get them?

- Repentance, desire and robust deedsGod is familiar with your coronary heart and that i pray that He courses youPlease understand that the judgment day is coming and you nevertheless have time to coachGod did no longer create you for no reasonyou have a option to bypass to hell or heavenyou're in charge on your strikesyou're no longer a sinner by utilising layout and Jesus did no longer die for sins of othersit particularly is not honest and God does no longer harm everyone for sins of othersPlease use your head and choose wisely, ensure now previously it gradual is updo no longer look ahead to Jesus, as he's not coming back, a minimum of no longer in accordance to Quraan and person-friendly sense (regardless of the incontrovertible fact that maximum Muslims and all christians have faith he's coming back)examine Quraan, understand the info10:36 yet maximum of them persist with no longer something yet fancy: relatively fancy might properly be of no avail against factVerily Allah is unquestionably attentive to all that they dofifty 3:28 yet they have no wisdom thereinThey persist with no longer something yet conjecture; and conjecture avails no longer something against fact40 seven:14 Is then individual who's on a sparkling (direction) from his Lord, not greater effective than one to whom the evil of his habit seems appealing, and which incorporate persist with their own lusts?

- Q: Why is that the aluminum atom is larger than the phosphorus atom, but the aluminum ion is smaller than the phosphorus ion?

- Put on a surgical mask and lets have some fun at my house! Bring a condom!

- Q: I have replaced the bulbs and the light will not workHubby says fuse needs to be replaced but I dont know how to do itAnd he wont do it for me.always at work or too tired! Thanks for your help!!!

- Fluorescent lights do not contain fusesThey contain a device called a ballast, which is a black brick-shaped device with a number of wires coming out; these occasionally fail, and can be replaced: new ones cost $10 to $20, depending on typeBut a more plausible failure point is the starter, which is a small aluminum cylindrical can-shaped device, about an inch long and 3/4 inch in diameterNOTE: many fixtures do not use starters, as the necessary functionality is provided by the ballastBut if yours does, try replacing it: turn the device about 1/8 turn to the left, and it will come outIt will have a designation such as FS-4 on it; get a replacement with the same designationStarters are cheapIf replacing the starter does not work, or there isn't one, replace the ballast: remove the old one (cut the wires that go to the lamps about in the middle of each wire, and unscrew the wire nuts that secure the black and white wires to the power supply) and take it to the hardware store for a suitable replacementTo install the new one, you will need some wire nuts to connect the wires from the new ballast to the old lamp socket wires.

- Q: what are some of the stable compounds that contain the element aluminum?

- Ores bauxite and cryolite, alumina (Al2O3), halides, sulfide, hydroxide, etc.

- Q: Im trying to remember how someone made pork chops in the oven a long time agoThey were very tender and nice to eatFrom what I can remember they used a baking pan and cooked them covered with aluminum foil for a long time in the oven with liquid (sometimes cream of mushroom soup).Does this sound familiar to anyone? What temp and how long should I bake (or braise) them?

- Very tender and juicy usually asks for long braising at low temperature.I never did this with chops before,but with chicken,turkey leg and bigger pieces of pork or beef.I never use any ready made stuff like cream of mushroom soup,but a little broth and wine or beer (depending on meat:beer is good with pork or maybe chicken:I have a really good recipe for chicken with a dark malty beer and mushrooms and French onions,very yummy,indeed!) you need only little liquid in a covered pan in the oven,therefore the sauce the sauce is more intense,especially if you spice it really good and add mushrooms (dried ones are more intense too) onions,garlic if you like,celery and carrots or tomato,bell pepper,chilli,maybe olives.Temperature between 100and 150 (maximum!) degrees C,I don't know exactly with chops (depends on how thick they are cut,how many you have) but I'd guess about 2-3h.On low temperature covered in oven they won't get dry if you bake them longer.Get out out the chops,keep them warm and bring to taste (or reduce if it is too thin) sauce.I do this often on sundays,when it doesn't have to be a fast meal.

Send your message to us

Aluminum Foil Faraday Cage Wholesale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords