Cosmetics Packaging Tape - Aluminum Foil Facing Resist High Temperature Reinforced

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 3000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

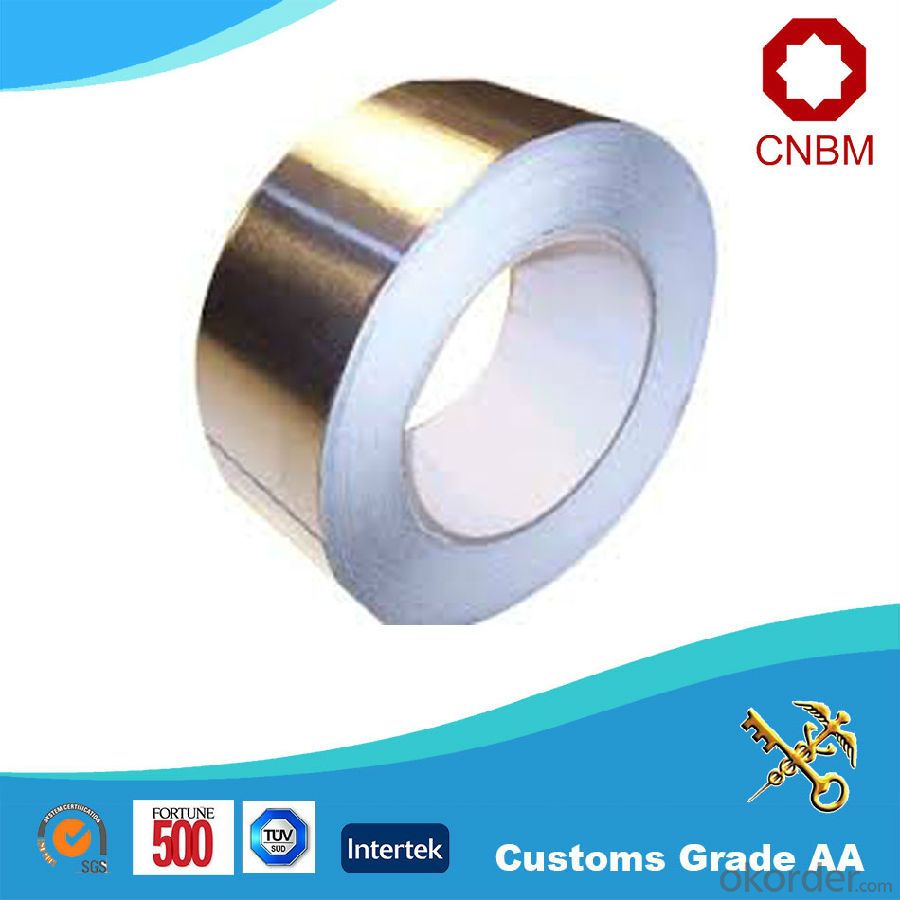

Aluminum Foil Facing Resist High Temperature Reinforced

Product Description

Aluminum Foil Tape is of aluminum foil as the carrier, coating with solvent based acrylic, synthetic rubber-resin, or water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

Features

Excellent adhension

Resistance to high temperature

Resistance to aging

Leave no residue

High mechanical strength and good impact resistance

Data Sheet

Item | Aluminum Foil Facing |

Thickness (micron) | 50 |

Peel Adhesion (N/25mm) | 16 |

Tensile Strength(N/25mm) | 35 |

Service Temperature (℃) | 60 |

Elongation (%) | 5 |

| Liner | White Release Paper |

Color | Silver |

Authorized Certificate

FAQ

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What are other tapes?

Cloth Tape: widely used for wrapping various material products etc.

PVC Tape: used for electrical application, floor marking and pipe wrapping.

3. How long can we send the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can packaging tape be used for sealing musical instruments or equipment?

- Packaging tape is not recommended for sealing musical instruments or equipment. It may not provide adequate protection or support, and could potentially damage the instrument or equipment. It is best to use specialized products designed specifically for sealing and protecting musical instruments or equipment.

- Q: Is packaging tape easy to write on?

- Writing on packaging tape can be quite difficult due to its smooth and glossy surface. Most writing tools struggle to stick properly to the tape, resulting in smudged or faded writing. Furthermore, the adhesive properties of packaging tape can cause ink to bleed, making it challenging to achieve clean and precise writing. As a solution, it is recommended to use a permanent marker or a specialized pen specifically designed for non-porous surfaces such as plastic. These writing tools typically yield superior outcomes and ensure that your writing stays legible and intact.

- Q: Does packaging tape come in different thicknesses?

- Yes, packaging tape does come in different thicknesses. Packaging tape is available in a variety of thicknesses to accommodate different needs and requirements. Thicker tapes are typically more durable and are suitable for heavy-duty applications where extra strength and resistance are necessary. On the other hand, thinner tapes are often used for lighter packages or general everyday use. The choice of thickness depends on the weight and size of the package being secured, as well as the level of reinforcement desired.

- Q: Can packaging tape be used for sealing plastic wrap?

- Typically, packaging tape is not employed for sealing plastic wrap. Its purpose lies in firmly sealing packages by adhering to cardboard and other surfaces. Conversely, plastic wrap is a thin, see-through film utilized to cover and safeguard food or other objects. It is usually sealed by pressing the edges together or utilizing a specific plastic wrap cutter. Although packaging tape may serve as a temporary seal, it is not intended for use with plastic wrap and may fail to provide a dependable or durable seal. It is advisable to adhere to the manufacturer's recommended method for sealing plastic wrap.

- Q: A tape of 2.5 cm thick, about how many meters

- The average Taobao buys tapes between 165 and 170 meters. Actually do look at the film thickness. Less film thickness and less rice. The membrane is thin and the rice is more

- Q: Can packaging tape be used for sealing retail or product packaging?

- Yes, packaging tape can be used for sealing retail or product packaging.

- Q: How do I prevent packaging tape from sticking to itself?

- To ensure packaging tape doesn't stick to itself, try inserting a small piece of wax or parchment paper between the layers. This acts as a protective barrier, preventing the sticky sides from touching. Another technique is to fold the tape's edges outward before cutting, providing a non-sticky portion to grip onto while using it. Alternatively, consider utilizing a tape dispenser equipped with a built-in blade or teeth for clean cuts, reducing the likelihood of self-adhesion.

- Q: How do I prevent packaging tape from getting tangled?

- To prevent packaging tape from getting tangled, here are a few tips: 1. Use a dispenser: Invest in a tape dispenser specifically designed for packaging tape. The built-in cutting blade and roller mechanism will help keep the tape controlled and prevent tangling. 2. Start with a clean surface: Before applying the tape, ensure the surface is clean and free from dust, debris, or any other potential obstacles that may cause the tape to stick and tangle. 3. Avoid excessive handling: Minimize handling of the tape as much as possible. Each time you touch the tape, there is a higher chance of it twisting or tangling. Try to handle the tape only when necessary. 4. Cut the tape cleanly: Use a sharp cutter or a dispenser with a cutting blade to make clean and straight cuts. Jagged or uneven cuts can cause the tape to twist or tangle as it is being unrolled or applied. 5. Store it properly: When not in use, store the tape in a cool and dry place, away from direct sunlight or extreme temperatures. Keeping the tape in its original packaging or a designated container can also prevent tangling. 6. Unroll carefully: When unrolling the tape, hold the roll firmly and apply a slight tension to keep it straight. Avoid jerky movements or pulling the tape too forcefully, as this can cause it to twist or tangle. By following these tips, you can minimize the chances of packaging tape getting tangled, making your packaging process smoother and more efficient.

- Q: Can packaging tape be used for sealing glass windows?

- No, packaging tape is not suitable for sealing glass windows. It is not designed to provide a strong and durable seal on glass surfaces. It is recommended to use appropriate window sealants or weatherstripping for this purpose.

- Q: Does packaging tape come in different materials for specific applications?

- Yes, packaging tape does come in different materials for specific applications. One common type of packaging tape is made of polypropylene, which is a versatile material suitable for general-purpose packaging. It is strong, durable, and resistant to moisture and temperature changes, making it suitable for a wide range of applications. However, for more specialized uses, different materials may be needed. For example, if you are packaging items that require extra security or tamper-evident features, you may opt for security tape. This type of tape is often made of a thicker and stronger material, such as polyester or reinforced paper, and is designed to leave a visible mark or message when tampered with. In certain cases, you may need to use packaging tape that is specifically designed for use in extreme temperature conditions. For instance, if you are shipping goods that will be exposed to freezing temperatures, you may need to use freezer-grade packaging tape that remains adhesive and effective in low temperatures. Similarly, some applications may require tape that can adhere to difficult surfaces like corrugated cardboard or recycled materials. In such cases, you may choose a packaging tape with aggressive adhesive properties or one that is specifically formulated for adhesion on challenging surfaces. Additionally, there are also eco-friendly options available for those who prioritize sustainability. Environmentally friendly packaging tapes are often made from renewable or recycled materials and use non-toxic adhesives. Overall, the choice of packaging tape material depends on the specific needs of the application, such as security, temperature resistance, surface compatibility, or environmental considerations. It is always important to select the appropriate tape to ensure the safe and secure packaging of your items.

Send your message to us

Cosmetics Packaging Tape - Aluminum Foil Facing Resist High Temperature Reinforced

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 3000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords