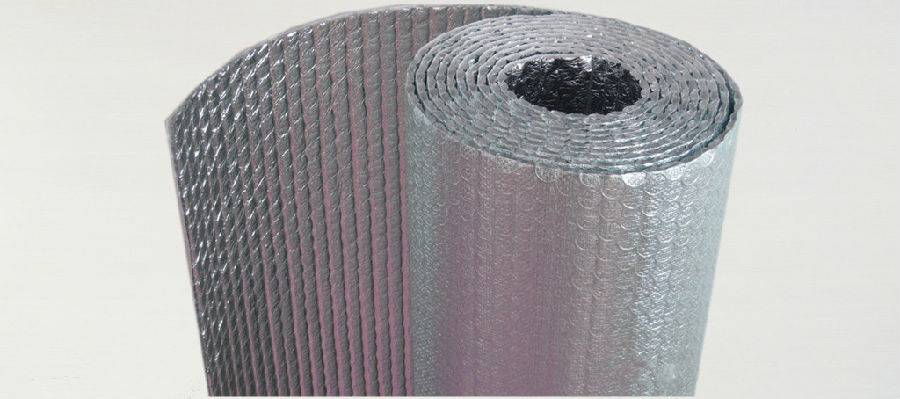

Aluminum Foil Facing Aluminum Foil with PET for Flexible Duct

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

tructure tructure | Normal laminated thickness | Width | Length | Color | ID | OD | Packin |

| AL+PET | 7umAlu+15umPet+3umGlue | 6mm-1000mm as your required | 500m-7000m | Silver blue bronze black others | 2"or3" | 250mm-600mm | polybag caron pallet

|

| 9umAlu+12umPet+3umGlue | |||||||

| AL+PET+AL | 6umAlu+15umPet+6umAlu+6umGlue | ||||||

| PET+AL+PET | 15umPet+7umAlu+15umPet | ||||||

| AL+PET+EAA | 7umAL+15umPET+25umEAA+6umglue | ||||||

| AL+PET+AL+EAA | 7umAlu+15umPET+7umAlu+25umEAA+9umglue | ||||||

| PET+PET | 15umPet+15umPet +3umGlue | ||||||

| Polyester Tape | 15um,18um |

Description: Al+PET Tape(AL/myler Tape) | ||||

Composition:aluminium foil and polyester film | ||||

Structure | Thickness(um) | Proportion(g/m2) | Elongation(%) | Strength(N/15mm) |

6um AL/12um PET | 20 | 36 | 30 | 2.7 |

7um AL/15um PET | 25 | 43 | 35 | 2.7 |

7um AL/20um PET | 30 | 50 | 35 | 3 |

9um AL/12um PET | 25 | 45 | 30 | 2.7 |

9um AL/15um PET | 30 | 49 | 35 | 3 |

9um AL/20um PET | 35 | 55 | 35 | 3 |

9um AL/25um PET | 38 | 62 | 35 | 4 |

12um AL/12um PET | 25 | 53 | 20 | 2 |

12um AL/15um PET | 30 | 57 | 20 | 3 |

12um AL/20um PET | 35 | 63 | 30 | 4 |

15um AL/15um PET | 30 | 65 | 20 | 3 |

25um AL/15um PET | 45 | 92 | 20 | 3 |

30um AL/25um PET | 60 | 119 | 20 | 3 |

30um AL/30um PET | 65 | 126 | 20 | 5 |

40um AL/30um PET | 75 | 153 | 20 | 5 |

40um AL/38um PET | 80 | 163 | 20 | 5 |

50um AL/25um PET | 90 | 173 | 20 | 5 |

50um AL/50um PET | 100 | 207 | 35 | 6 |

Above values refer to our current production and must be intended as average values | ||||

- Q: What precautions should be taken when using aluminum foil facing in construction or other applications?

- <p>When using aluminum foil facing, safety measures include ensuring proper ventilation to prevent build-up of fumes, wearing protective gear such as gloves and masks to avoid skin and respiratory irritation, and following manufacturer's guidelines for safe handling and application. It's also crucial to avoid contact with open flames or high heat sources as aluminum foil can melt or ignite. Always clean up spills immediately to prevent slipping hazards and ensure that the working area is well-lit to avoid accidents.</p>

- Q: Describe the most effective method for folding aluminum foil edges to seal food packaging.

- <p>The best way to fold aluminum foil facing for food packaging involves a few simple steps. Start by placing the food in the center of the foil. Bring two opposite edges of the foil together over the food, ensuring they overlap slightly. Fold one edge over the other, creating a seam. Press down firmly to seal. Repeat this process with the remaining two edges, ensuring all edges are sealed tightly. For added security, you can fold the edges inward to create a double seam. This method prevents leakage and keeps the food fresh and protected during cooking or storage.</p>

- Q: Is inhaling aluminum oxide particles from aluminum foil dangerous to health?

- <p>Breathing in aluminum oxide particles is generally not harmful in small amounts, as the human body can handle trace amounts of aluminum. However, prolonged exposure to high concentrations of aluminum oxide dust can cause respiratory issues and may have potential health risks. It is always advisable to handle aluminum foil and other materials that could generate dust in a well-ventilated area to minimize the risk of inhalation.</p>

- Q: This question asks for signs or methods to identify if the aluminum foil facing of a product, such as insulation or a jacket, is damaged or defective.

- <p>To determine if your aluminum foil facing is damaged or defective, look for visible signs such as tears, punctures, or holes. Check for any discoloration or rust, which could indicate corrosion. The foil should be smooth and uniform; any irregularities or bubbling might suggest a defect. Additionally, test the integrity by gently pulling or pressing the foil鈥攊f it easily tears or crumples, it may be compromised. For insulation, a damaged foil facing can lead to reduced effectiveness in heat or cold retention, so also consider the performance of the item.</p>

- Q: Is it safe to use aluminum foil as a cooking surface? If yes, what kinds of foods are suitable for cooking with aluminum foil?

- <p>Yes, aluminum foil can be used for cooking, but it's important to use it safely. It's suitable for wrapping foods like fish, meats, and vegetables to retain moisture and flavor. It's also used for making packets for steaming or baking, and for lining baking sheets to prevent sticking. However, avoid using it with acidic foods or at high temperatures as it can react with the food or release aluminum into the food. Always use heavy-duty aluminum foil for cooking to ensure it can withstand the heat.</p>

- Q: What are the eco-friendly options available to replace plastic containers?

- <p>Yes, there are several alternatives to plastic containers that are more environmentally friendly. Glass containers are a popular choice due to their durability and ability to be reused multiple times. Stainless steel containers are also a great option as they are long-lasting and do not leach chemicals. Biodegradable materials like bamboo, silicone, and certain types of plant-based plastics are other alternatives. Additionally, using cloth bags or reusable food wraps can help reduce the need for single-use plastic containers.</p>

- Q: What are the unique cleaning techniques for maintaining aluminum foil facing surfaces?

- <p>Aluminum foil facing requires gentle cleaning to avoid scratching the surface. Use a soft cloth or sponge with warm water and mild dish soap to clean the surface. Avoid abrasive materials like steel wool or harsh chemicals, as they can damage the aluminum. After cleaning, dry the surface thoroughly to prevent water spots. For stubborn stains, a mixture of water and white vinegar can be used, but always test on a small, inconspicuous area first. Regular cleaning will help maintain the appearance and functionality of aluminum foil facing.</p>

- Q: What are the potential health hazards linked to the use of aluminum foil facing?

- <p>The use of aluminum foil facing in construction or insulation can potentially pose health risks. Inhalation of aluminum dust can lead to respiratory issues, and long-term exposure may contribute to neurological problems. There's also a concern about the leaching of aluminum into food when using aluminum foil for cooking or food wrapping, which some studies suggest could be linked to Alzheimer's disease, although this link is not definitively proven. It's important to handle aluminum foil facing with care, ensuring proper ventilation and protective gear during installation to minimize health risks.</p>

- Q: What are the most suitable materials for creating aluminum foil facing?

- <p>The best materials for making aluminum foil facing are typically aluminum alloys, specifically 1100, 3003, or 8011 series alloys. These alloys offer excellent formability, corrosion resistance, and reflectivity, which are crucial for applications like insulation, construction, and heat management. Additionally, the facing material often includes a layer of polyester or polyethylene film to enhance durability and prevent tearing. The choice of material can also depend on specific requirements such as temperature resistance, UV resistance, and environmental conditions.</p>

- Q: What are the various materials used as facings for aluminum foil, and how do they differ from one another?

- <p>Aluminum foil facing materials are used in construction and insulation to provide a barrier against air and moisture. The different types include: 1) Kraft paper facing, which is a strong, absorbent paper used for general purposes; 2) Glassine facing, a thin, glossy paper with good water resistance; 3) PE-coated facing, where a layer of polyethylene is applied for enhanced water resistance; 4) Aluminum foil facing, which is a thin layer of aluminum for superior barrier properties; 5) Silicone-treated glass fabric, offering high-temperature resistance and used in high-performance applications. Each type has unique properties affecting their use in various applications.</p>

Send your message to us

Aluminum Foil Facing Aluminum Foil with PET for Flexible Duct

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords