Aluminum Foam for Flooring underlayment foam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

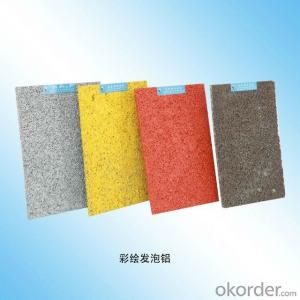

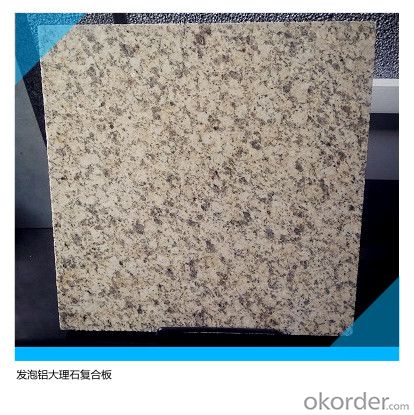

100% Recycling Soundproofing Closed Cell Aluminum Foam Panel

What is AluminumFoam?

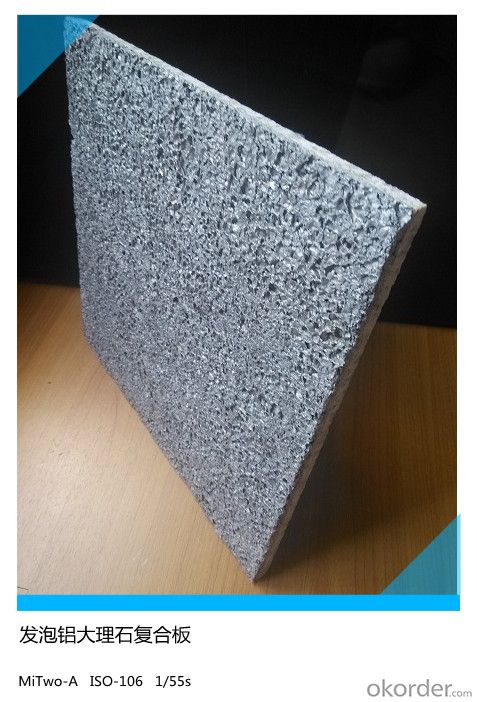

Aluminum foam is a new concept metalmaterial which is foamed in sponge shape after melting aluminum ingot with various chemical ingredients and has many bubble layers inner structure.

Porous material is much lighterthan original one, which is the characteristic of porous. And, it improves the ability of energy absorption and reduces the abilityof thermal and electrical conductivities than original metal materials. Inaddition, porous material has wide applications as well as excellent ability ofsound absorption and permeability of liquid, air, etc.

Aluminumfoam, a metal itself, can be applied to aerospace aviation required the thermostability over 200℃. It is a 100% recyclabl ecofriendly material and absolutely will not produceharmful substances no matter in the process of producing, using or abandoning.

Main properties of aluminum foam

Density is 0.2~0.4g/cm3 (Aluminium1/10,Iron1/30, and Wood 1/4)

Soundabsorption

Porous structure has a good soundabsorption.

Aluminum foam sound-absorbing materialcan be used in the inner decoration of buildings (walls, ceiling and floor),railway, highway, factories, mechanical equipment and any other fields.

Suitable for noisy place.

100%non-flammability and no toxic gas released when burning.

Non-combustibility TEST verified to be qualified. <KIMM; IMO A.799 (19)>

I grade Non-flammability TEST ofaluminum foam surface verified to be qualified. <KICT; KS F2271>

Energyabsorption

Porous structure can effectively absorbenergy.

Have a great effect on energyabsorption after a high impact.

Firstly acquired the national SB5class (Guard rail shock-absorber)

Electromagnetic wave shielding ability

Aluminum foam has a function ofabsorbing electromagnetic wave

Widely used in military (stealth materials),TV station, hospital and any other electromagnetic shielding places.

100% recyclable Aluminum foam is nonpoisonous, odorless andharmless, no toxic gas released when burning.

Aluminum foam can be produced by recycled aluminum andits scraps.

ProductFeatures

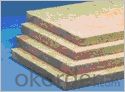

Item | Aluminum foam composed panel | Aluminum honeycomb plate |

Material | Aluminum | Aluminum |

Structure | Aluminum plate(GRP plate) aluminum foam aluminum plate(GRP plate) | Aluminum plate(GRP plate) aluminum honeycomb aluminum plate(GRP plate) |

(long time immersion and corrosion in water) | Excellent(oxidized pure metal) | Excellent but easy to rust |

Excellent (Non-flammability of pure metal) | General (Glue layer in the middle is not resistant to high temperature) |

ComparisonAluminum Foam with Other Sound-absorbing Materials

Type | Aluminum Foam | Polyester | Glass Fiber | Urethane Form |

Shape |

|

|

|

|

Material | Aluminum | Polyester | SiO2, mineral | high molecular Material |

Acoustic absorption(NRC Standar d) | over 0.70 | over 0.70 | over 0.75 | over 0.65 |

Long-term sound absorption | Permanent | Property is decreased | Property is decreased | Property is decreased |

Eco-friendly | 100% recyclable Eco-friendly | No recyclable, flammable, produce little dust | No recyclable, no flammable, arsenic acid cause gas pollution | No recyclable and flammable |

Materials handling & Constructability | Easy handling, using and working under no protective equipment | No damage when handling and using, easy to work under no protective equipment | Low stability. Easy to cause respiratory disease and skin ailments when touching | No damage when handling and using, easy to work under no protective equipment |

Human harmfulness | Harmlessness | Harmlessness | Harmfulness | Poisonous gas (CO, Cyan gas) release when burning |

Waterproofness & Sound absorption | Waterproofness is excellent , stable form, permanent sound absorption | Waterproofness and adhesion is good, stable form | Absorb moisture and poor drainage cause lower acoustic absorption | Absorb moisture and poor drainage cause lower acoustic absorption |

Non-flammability | Ⅰgrade Non-flammability | Heat-resistant | Easy flammable |

- Q: Composite floor sound how to deal with

- Solution: (1) with the muffler if the floor is not sound, or local sound, and maintenance is not convenient circumstances, you can first buy a special wood muffler smear, a slight noise can be eliminated, If the sound is too large to a certain extent, reduce the maintenance at the appropriate time. (2) local resurfacing will be abnormal sound knocked out, Dilong handle the new floor to fill in. (3) all resurfacing If it is because the floor itself, or the pavement process is not compliance and other issues, resulting in a lot of places where the sound, or the ground did not leveling, the proposed resurfacing, the cost of all the resurfacing When the sub-shop, pay attention to the ground leveling, to ensure that the ground leveling layer leveling you want to have enough dryness, to ensure that moisture content within 8% to lay the keel, if it is wood keel, brush pest and paint a paint, Or perennial in the rainy and humid season, then the keel can also add a layer of wool floor or linoleum, so as not to deformation of the floor moisture, laying a good attention to the maintenance of the floor.

- Q: Strengthen the composite floor of the inspection standards which

- Strengthen the composite floor of the inspection standards which

- Q: What are the advantages and disadvantages of solid wood flooring?

- Solid wood composite flooring advantages and disadvantages are the following: 1) solid wood flooring retains the solid wood flooring natural texture, foot feel comfortable features. 2) solid wood flooring and both strengthen the floor wear, easy to install, clean up the characteristics. 3) I solid wood flooring is very suitable for warm home decoration. 4) solid wood composite floor hardness than the floor is very small, very suitable for home with the elderly and children decorated family. 5) Solid wood flooring prices between the solid wood flooring and solid wood flooring of the method of prostitutes prostitutes 诓 magic ride between Wei and glass, belonging to the middle consumption of water balance, is the majority of the family can accept the scope of consumption. 6) solid wood flooring installation is simple, easy to clean up, no solid wood flooring so delicate. 7) solid wood flooring decoration effect is very good, many varieties, such as: solid wood composite antique floor, solid wood parquet flooring. Solid wood flooring is the lack of places: solid wood flooring is made of multi-layer floor, will contain a small amount of formaldehyde.

- Q: How is the maintenance of the new floor laminate?

- Buy the floor on the Internet Bell, just paved, the new floor needs maintenance? More

- Q: Just installed a composite floor, because the brush of the porcelain led to a lot of gray floor, wiped many times are difficult to clean, how should I do? More

- First with grinding wax to play side, and then polished wax again on the ok, the two wax prices are not expensive in 15 yuan.

- Q: Newly renovated bedroom to meet the floor brand is the classic November last year to do the new floor flooring is not stained with water is now a local area appears a little bit up on the above had a clear feeling at first I thought it was the thermal expansion and contraction of the reason also Did not care about the weather is now warm, but the floor or the saddle of the jar of the intimate visit Gui poems into the stream must ask what method can be restored ah did not install the floor before my bedroom hit the water leveling equipment invited people to help me think rut Thank you more

- Repair can not only change, there should be noted that when the floor remember to see if the ground is back to the serious!

- Q: I am all inclusive to the decoration company. Decoration company recommended to strengthen the floor under the floor put mat, their reason is the guest restaurant and corridor paste tiles, if the bedroom keep the pad is not the same height. But my friend suggested that I strengthen the composite floor under the release of moisture-proof pad, helium Fu Fu Huang Bing Hao Feng kettle pad to keep a long time will be uneven. In the end which kind of better please enlighten God. More

- If it is a pavement treasure, there is a drawback, that is, some places will have a squeaky sound, feeling particularly soft!

- Q: Solid wood flooring installation need to pay attention to it

- Do not understand, to complete the task only

- Q: How to install the composite floor

- I would like to love the rich floor, at home improvement, I met all the service providers, rich round floor of the service is the best, the installation master will take the initiative to tell you some knowledge about the floor of the conservation, which is still on the customer Attention to. We rely on the burden of fear of spending with the spree, sometimes in addition to quality, not also in addition to a service attitude Well ~ - ~

- Q: Home shop is a composite floor, five years, the recent total in the door seams found similar nibble sweater insects, dark red, big head small tail, the tail there are long hair, some hard, but also molting, a centimeter long, Ask the experts to answer what's going on? Began to think that the wool is born, and later found not, because the total appearance, clean up a seam, stop two or three days to see there, so I suspect the floor insects, and how to do? Why the composite floor will be raw insects? Home decoration is the ground Qinghu raft Hong Kong fan drum song attack card sweep is very clean, under the floor is the bubble and plastic, according to reason not raw ah, please professional answer! Other answers I have seen not suitable for me, do not paste it! The The More

- Demolition of the floor to find the root cause is the right way, the vitality of insects strong, there are too many insecticides harmful to the body

Send your message to us

Aluminum Foam for Flooring underlayment foam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords