5052 H32 High Quality Aluminum Fin Heat Exchanger Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Fin Heat Exchanger Coils Description:

Alloy Aluminium Plate 1200 is widely used in the strength requirements of the product. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminum Fin Heat Exchanger Coils:

PVC Protect Film

Waterproof paper

High Quality

Competitive Price

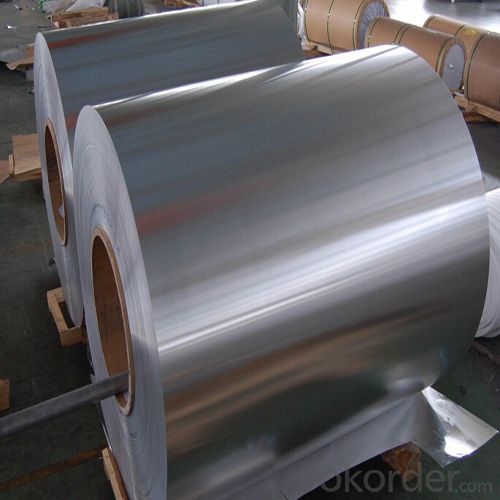

3. Aluminum Fin Heat Exchanger Coils Images:

4. Aluminum Fin Heat Exchanger Coils Specification:

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 0.2-200mm aluminium 5050 H38 |

Width | 1250mm 1000mm or as your requirements |

Length | 3000mm 5800mm or as your requirements |

MOQ | 5 Ton |

Package | Standard export package, by wooden box or as require |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What is the corrosion resistance of aluminum coils in saltwater environments?

- Aluminum coils have excellent corrosion resistance in saltwater environments. This is due to the formation of a protective oxide layer on the surface of the aluminum, which acts as a barrier against corrosion. This oxide layer prevents the saltwater from coming into direct contact with the aluminum, effectively reducing the risk of corrosion. Additionally, aluminum is inherently resistant to saltwater corrosion because it is a relatively inert metal. As a result, aluminum coils are commonly used in various marine applications, such as boat hulls, offshore structures, and saltwater cooling systems. However, it is important to note that prolonged exposure to saltwater can still result in some level of corrosion over time. Regular maintenance and appropriate protective coatings can help enhance the longevity and performance of aluminum coils in saltwater environments.

- Q: What are the typical delivery options for aluminum coils?

- Delivery options for aluminum coils can vary depending on the supplier and customer's requirements. However, there are several common options available. 1. Direct delivery: Many suppliers offer the convenience of delivering the coils directly to the customer's location. This is particularly useful for customers who need large quantities or have limited transportation capabilities. The supplier will make arrangements for transportation, using trucks or shipping containers, to deliver the coils directly to the customer's facility. 2. Pickup from supplier: Customers also have the choice of arranging their own transportation and collecting the aluminum coils from the supplier's location. This option is often preferred by customers who are located nearby or already have their own transportation logistics in place. 3. Third-party logistics (3PL): Some suppliers collaborate with specialized logistics companies to handle the delivery of aluminum coils. These companies have expertise in transportation and offer efficient and cost-effective delivery services. Customers who prefer to outsource their logistics operations often choose this option. 4. International shipping: Customers requiring international delivery of aluminum coils have the option of using air or ocean freight. However, these methods may involve additional costs and longer delivery times due to customs clearance and transportation logistics. It's important to note that the specific delivery options may vary depending on the supplier's capabilities and the customer's location. Therefore, it is recommended to directly discuss delivery options with the supplier to ensure the most suitable and cost-effective method is chosen.

- Q: What is the profit of aluminium coil gate?

- Market prices are almost transparent, the price can be said to earn a installation costs, two people installed, then, in addition to costs, profits of about 4 thousand and 500

- Q: I have a muffin pan made of aluminum foil and I do not know if i can put it in the oven to cook some muffins. Many sights say it will melt but they say that about putting a sheet of foil at the bottom of the oven for a long time. I just want it to be in their for half an hour to make muffins.

- Aluminum foil is made for the oven. You can keep aluminum foil in there for hours. The aluminum foil pan you have are the disposable ones. You use those once or twice and throw them away. They will be just fine! I've used them plenty of times. They're convenient b/c if you're bringing muffins to someone- you can bring them in the aluminum container and don't care about getting the container back.

- Q: What are the different coil transportation options for aluminum coils?

- There are multiple transportation options available for aluminum coils, each offering their own advantages and suitability depending on various factors. These include: 1. Utilizing flatbed trucks: Commonly employed for aluminum coil transportation, flatbed trucks feature an open top and a flat, open trailer bed. To ensure secure transportation, the coils are firmly strapped or banded onto the bed, minimizing any potential movement. 2. Employing coil racks: Specifically designed for carrying aluminum coils, coil racks are specialized transportation equipment typically made of steel. These racks are placed within trucks or trailers, enabling the coils to be stacked and held in place by dividers, ensuring no shifting or damage occurs. 3. Opting for coil trailers: Specifically created for the transportation of aluminum coils, coil trailers possess a unique coil cradle system designed to securely hold the coils during transit. These cradles are adjustable, accommodating various coil sizes and preventing any potential movement or harm. 4. Considering container shipping: Another alternative for aluminum coil transportation involves the use of shipping containers. By loading the coils into the containers and securing them with straps or bracing, this option is frequently utilized for international transportation due to the ease of loading containers onto ships or trains. 5. Selecting rail transport: Rail transport presents an additional option for aluminum coil transportation, particularly for long-distance journeys. Specialized rail cars, known as coil cars, incorporate cradles or racks to securely hold the coils throughout the transit. This method is often chosen for its cost-effectiveness and efficiency. Ultimately, the selection of a suitable coil transportation option is dependent on factors such as distance, cost, and the specific requirements of the coils being transported.

- Q: Can the displacement sensor be used for real-time measurement of the aluminum coil thickness?

- You are suggested to use eddy current displacement sensor KD2306 to measure aluminum.

- Q: Can aluminum coils be used in power generation facilities?

- Yes, aluminum coils can be used in power generation facilities. Aluminum has excellent thermal conductivity, making it an efficient choice for heat transfer applications in power generation equipment such as heat exchangers and condensers. Additionally, aluminum's lightweight nature and corrosion resistance make it a viable option for various power generation processes, including wind turbines and hydroelectric power plants.

- Q: Can aluminum coils be used for electrical enclosures?

- Electrical enclosures can indeed utilize aluminum coils. Aluminum, being a lightweight and durable substance, boasts exceptional electrical conductivity and heat dissipation capabilities. Furthermore, it exhibits commendable resistance to corrosion, rendering it appropriate for diverse environmental circumstances. Due to its malleability, aluminum coils effortlessly adopt various shapes and sizes, rendering them highly adaptable for enclosure designs. Moreover, aluminum represents a cost-effective alternative when compared to metals such as stainless steel. Nonetheless, it remains crucial to guarantee adequate insulation and grounding to avert any potential electrical hazards when employing aluminum coils in electrical enclosures.

- Q: What is the thickness tolerance of aluminum coils?

- The thickness tolerance of aluminum coils varies depending on the grade and manufacturing process. Typically, aluminum coils have a standard thickness tolerance of approximately +/- 0.005 inches (+/- 0.13 mm). However, it is important to note that this tolerance can be further adjusted or refined based on the specific requirements of the customer and the capabilities of the manufacturer. Certain specialized aluminum coil manufacturers may offer even tighter thickness tolerances, usually around +/- 0.002 inches (+/- 0.05 mm), to cater to more precise or demanding applications. To ensure the desired thickness tolerance is met for a specific project or application, it is always recommended to consult with the manufacturer or supplier.

- Q: What are the potential applications of coil-stucco aluminum coils?

- Coil-stucco aluminum coils have a wide range of potential applications due to their unique properties and characteristics. Some of the potential applications of coil-stucco aluminum coils include: 1. Building and construction: Coil-stucco aluminum coils are commonly used in the construction industry for various purposes. They can be used for roofing, cladding, and siding applications, providing durability, versatility, and aesthetic appeal to buildings. The stucco finish on the coils adds texture and enhances the overall appearance of the building. 2. Transportation industry: Coil-stucco aluminum coils are also used in the transportation industry for manufacturing trailers, truck bodies, and other vehicles. Aluminum is lightweight, yet strong, making it an ideal material for reducing the weight of vehicles and increasing fuel efficiency. The stucco finish on the coils provides additional strength and resistance to scratches and abrasions. 3. Appliances and electronics: The coil-stucco aluminum coils are suitable for manufacturing appliances and electronics due to their corrosion resistance and thermal conductivity. Aluminum coils are commonly used in refrigerators, air conditioning units, and other household appliances. The stucco finish provides an added layer of protection against wear and tear. 4. Signage and advertising: Coil-stucco aluminum coils are widely used in the signage and advertising industry for making outdoor signs, billboards, and displays. The stucco finish enhances the visibility of the signs by reducing glare and reflections. Additionally, aluminum is a weather-resistant material, making it suitable for outdoor applications. 5. Packaging industry: Coil-stucco aluminum coils find applications in the packaging industry as well. Aluminum is a non-toxic and non-reactive material, making it suitable for packaging food and beverages. The stucco finish adds an attractive texture to the packaging material, making it visually appealing. 6. Industrial applications: Coil-stucco aluminum coils are used in various industrial applications such as manufacturing equipment, storage tanks, and processing systems. The excellent corrosion resistance, high thermal conductivity, and strength make aluminum coils a preferred choice in industries where these properties are crucial. Overall, the potential applications of coil-stucco aluminum coils are diverse and extensive. The unique properties of aluminum, combined with the stucco finish, make these coils suitable for a wide range of industries, including construction, transportation, appliances, signage, packaging, and industrial applications.

Send your message to us

5052 H32 High Quality Aluminum Fin Heat Exchanger Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords