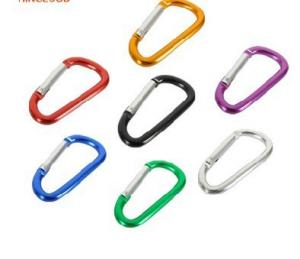

Aluminum Engraved Logo Carabiner Key Chain

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Buying Procedures

Enquiry: contact us by email, phone call, fax, Instant tools (Trademanager, MSN, Skype) and let us know your enquiry.

Discussion: specify the items you desire, confirm specification; OEM/ODM consultation.

Quotation: Prices offered and accepted.

Place order as per contract or discussion.

Proforma invoice offered to double confirm the order for both-side records.

Payment settled.

Order completed under our arrangement.

Goods shipped as per contracted term.

Goods arrive at local port or warehouse, depending on contracted term.

Support & re-ordering.

Specifications

D Shape Carabiner Key Chain

1.Logo ,OEM accept

2.CE,ROHS pass

3.promotional items

4.MOQ:1000pcs

| Product: | D Shape Carabiner Key Chain |

| MOQ: | 1000pcs |

| Material: | eco-friendly Aluminum |

| Color: | available or as Pantone Colors |

| Sample Time: | a.1-2day without logo,you pay the express fee; b.3-4 Days for printing logo,sample fee will be refund to you when place order. |

| Production Time: | a.Normal Time:10-15 Days for small quantity; b.It depends on order quantity |

| Packing: | 1pc/opp,100pcs/opp,1000pcs/ctn or customized |

| Logo: | Silk-screen Print,Laser,Engraved,Sticker, Epoxy etc |

| Shipping: | a.By air :DHL,UPS,FEDEX,TNT,EMS etc b.By sea |

| Payment Term: | T/T, Paypal, Western Union |

Packaging & Delivery

| Packaging Detail: | 1pc/opp,100pcs/opp,1000pcs/ctn or as client's request. |

| Delivery Detail: | available 10-15 Days,or it depends on order quantity |

Our Service

Your inquiry related to our product & price will be replied within 24hours.

Well-trained & experienced staff are to answer all your inquiries in English of course.

Working time: 8:30am ~6:00pm, Monday to Friday(UTC+8).

OEM & ODM projects are highly welcomed. We have strong R&D team here to help.

Your business relationship with us will be confidential to any third party.

Good after-sale service offered, please get back if you got question.

Suggestion

Please kindly check the packages after you receive the goods, if you got wrong products/ quality problem/short quantity, please get back to us as priority. Please note that you need to send us pictures of the defective items concerning this, and we will consider to replace or refund accordingly.

- Q: Is it possible to utilize recycled aluminum for the production of jewelry and fashion accessories?

- <p>Yes, recycled aluminum can be used to make jewelry and other fashion accessories. Recycled aluminum is a sustainable and cost-effective alternative to new aluminum, and it maintains the same properties as newly mined aluminum. It is lightweight, durable, and can be easily molded into various shapes and designs. Many fashion designers and jewelers are increasingly using recycled aluminum to create unique and eco-friendly products, reducing the environmental impact of their creations.</p>

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a roofing material.

- <p>Advantages of using aluminum sheets for roofing include their lightweight nature, which reduces structural load; corrosion resistance, making them suitable for coastal areas; and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Disadvantages include the potential for dents and damage from hail or heavy impacts, and they can be more expensive than some other roofing materials. Additionally, aluminum can be noisy during rain, and it may require more frequent replacement compared to some other materials due to its lighter gauge.</p>

- Q: This question asks for methods to determine the presence of aluminum in an alloy.

- <p>To determine if an alloy contains aluminum, one can use various analytical techniques. A common method is spectroscopy, which can identify the presence of specific elements by analyzing the wavelengths of light absorbed or emitted. Another approach is the use of a spark test, where a sample is struck against a grinding wheel to produce sparks; the color and pattern of these sparks can indicate the presence of aluminum. Chemical tests, such as the reaction with sodium hydroxide, can also be used, as aluminum reacts with NaOH to produce hydrogen gas. Lastly, X-ray fluorescence (XRF) is a non-destructive technique that can accurately determine the elemental composition of an alloy, including aluminum content.</p>

- Q: This question asks about the process through which aluminum deteriorates over time due to environmental factors.

- <p>Aluminum corrodes through a process called oxidation. When exposed to air, aluminum reacts with oxygen to form a thin, protective layer of aluminum oxide on its surface. This layer prevents further corrosion. However, in the presence of moisture, acids, or other corrosive substances, the aluminum oxide layer can break down, leading to further oxidation and eventual pitting or thinning of the aluminum. The rate of corrosion can be influenced by factors such as temperature, humidity, and the presence of impurities in the aluminum. Proper protective measures, such as coatings or anodizing, can help prevent or slow down the corrosion process.</p>

- Q: Can the recycling of aluminum be done in a closed loop system without any degradation in the material's quality?

- <p>Yes, aluminum can be recycled using a closed loop process without losing quality. Aluminum is infinitely recyclable, meaning it can be recycled over and over again without losing its properties. The recycling process involves melting the aluminum, which is much less energy-intensive than the original production from raw materials. This closed-loop recycling system helps maintain the quality of aluminum, making it an environmentally friendly and sustainable material.</p>

- Q: What are the effects of aluminum on water quality, and how does it impact aquatic ecosystems?

- <p>Aluminum can significantly affect water quality, particularly in acidic conditions. It becomes more soluble and bioavailable in water with low pH, which can occur due to acid rain or natural soil acidity. High levels of aluminum can be toxic to aquatic life, causing physiological stress and even death in fish and other organisms. It can damage gill tissues, impairing respiration, and affect reproduction and growth. Aluminum can also bind to organic matter in the water, affecting nutrient cycling and potentially leading to eutrophication. In addition, aluminum can leach into water from various sources such as antiperspirants, which can contribute to its presence in aquatic environments.</p>

- Q: Is it possible to develop allergies from exposure to aluminum found in food packaging materials?

- <p>While aluminum is commonly used in food packaging materials, the risk of allergic reactions to aluminum is generally low for most people. Aluminum is not a known allergen, and exposure through packaging is typically minimal. However, individuals with a rare condition called contact dermatitis may experience skin irritation from aluminum. For the general population, the risk of allergic reactions due to aluminum in food packaging is negligible. It's always important to monitor any unusual reactions and consult a healthcare professional if concerned.</p>

- Q: This question asks for common uses of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight, corrosion resistance, and affordability. Some applications include: 1) Food and beverage cans for preserving food and drinks. 2) Aluminum foil used for cooking and food storage. 3) Construction materials, such as window frames and roofing. 4) In transportation, like car parts and airplane components to reduce weight. 5) Electrical wiring due to its high conductivity. 6) Household items like pots and pans, and furniture. 7) Packaging materials for various products. 8) In sports equipment like bicycle frames and tennis rackets. These applications highlight aluminum's versatility and importance in everyday life.</p>

- Q: Is aluminum a component in the manufacturing processes of glass and ceramics?

- <p>Aluminum can be used in the production of glass and ceramics, although it is not a primary component. In glassmaking, aluminum is sometimes added to reduce the coefficient of expansion, making the glass more resistant to thermal shock. It can also improve the chemical durability and electrical insulation properties of the glass. In ceramics, aluminum compounds are used as opacifiers, colorants, or to enhance the mechanical properties of the final product. However, the use of aluminum in these industries is typically in small quantities and serves specific purposes rather than being a fundamental part of the material composition.</p>

- Q: Describe the process of manufacturing aluminum from its raw materials to the final product.

- <p>The manufacturing process of aluminum involves several key steps. Initially, bauxite ore, the primary source of aluminum, is mined. The ore is then crushed and washed to remove impurities. Next, the bauxite is processed through the Bayer process, which involves digestion in a caustic soda solution to produce a solution of sodium aluminate. This solution is then seeded with aluminum hydroxide, causing crystals to form, which are then filtered out, washed, and calcined to produce aluminum oxide, also known as alumina. Finally, in the Hall-H茅roult process, alumina is dissolved in a cryolite bath and electrolyzed to extract pure aluminum. This process involves passing an electric current through the bath, causing aluminum ions to be reduced and collected at the cathode as molten aluminum, which is then tapped off and cast into various forms for use in manufacturing.</p>

Send your message to us

Aluminum Engraved Logo Carabiner Key Chain

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords