Aluminum Deep Drawing Quality Discs and Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminum Discs circles with Deep Drawing Quality Description

• Product: Aluminim Circle

• Application: It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

• Advantage: Deep drawing and hard anodizing quality Aluminum Circle Sheet can be supplied. Our Aluminum Circle is RoHS and REACH compliance and uses well-protected packing. Our circles are excellent material for producing cookware, utensil, pots, pans and kettles.

2.Main Features of the Aluminum Discs circles with Deep Drawing Quality

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

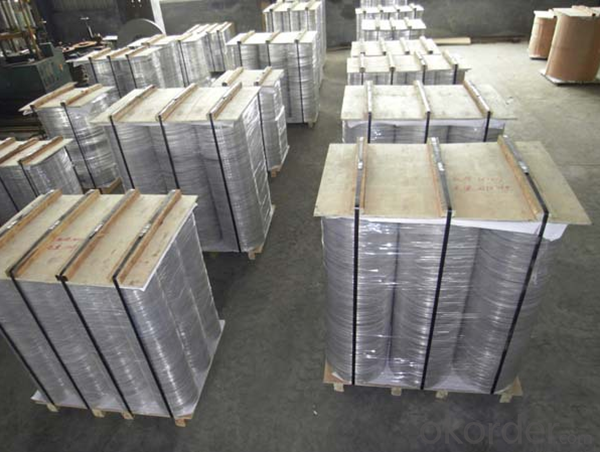

3. Aluminum Discs circles with Deep Drawing Quality Images

4.Aluminum Discs circles with Deep Drawing Quality Specification

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

5.FAQ of Aluminum Discs circles with Deep Drawing Quality

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: This question asks for a list of typical metal alloys that are utilized in the production of cars.

- <p>Common alloys used in automobile manufacturing include steel alloys such as low carbon steel, high-strength steel, and stainless steel for body and frame construction. Aluminum alloys are also widely used for their lightweight properties, especially in engine components and body panels. Magnesium alloys are employed for parts requiring high strength-to-weight ratios. Additionally, cast iron is used for engine blocks and cylinder heads, while copper alloys are utilized in radiators and electrical wiring. Titanium alloys find use in high-performance or luxury vehicles for their exceptional strength and low weight.</p>

- Q: This question asks for a description of the characteristics that are inherent to pure aluminum.

- <p>Pure aluminum is a lightweight, silvery-white metal known for its excellent malleability, ductility, and electrical conductivity. It has a density of 2.7 g/cm鲁, which is about one-third that of steel. It is non-magnetic and has a low melting point of 660掳C (1220掳F). Pure aluminum is also highly reflective, making it useful in mirrors and reflective coatings. It is a good thermal conductor and is resistant to corrosion due to the formation of a protective oxide layer on its surface. However, it is soft and lacks strength, which is why it is often alloyed with other elements to improve its mechanical properties.</p>

- Q: What are the various applications of aluminum oxide in different industries and daily life?

- <p>Aluminum oxide, also known as alumina, has a wide range of applications due to its hardness and other properties. It is used as an abrasive in products like sandpaper and grinding wheels. In the electronics industry, it serves as a substrate for semiconductor devices. It's also a key component in the production of aluminum metal through the Hall-H茅roult process. In the medical field, aluminum oxide is used in dental materials and as an antiperspirant. Additionally, it's found in cosmetics, ceramics, and as a catalyst in various chemical processes.</p>

- Q: Is it possible to utilize aluminum as a material for automotive construction?

- <p>Yes, aluminum is commonly used in cars. It is valued for its lightweight properties, which can improve fuel efficiency and reduce emissions. Aluminum is used in various parts of a vehicle, including engine components, body panels, and suspension systems. Its high strength-to-weight ratio and resistance to corrosion make it an ideal material for automotive applications.</p>

- Q: This question asks about the energy consumption involved in the recycling process of aluminum.

- <p>Recycling aluminum requires significantly less energy compared to producing aluminum from raw materials. It takes about 5% of the energy needed to produce new aluminum from bauxite ore. This energy efficiency is due to the fact that recycling aluminum involves melting down the metal, which requires less energy than the extraction and refining processes involved in primary production. The exact amount of energy saved can vary depending on factors such as the purity of the recycled material and the efficiency of the recycling process, but overall, recycling aluminum is a much more energy-efficient method than mining and refining new aluminum.</p>

- Q: Is it possible to utilize aluminum in the creation of innovative battery technologies?

- <p>Yes, aluminum can be used to make new types of batteries. Aluminum-air batteries, for instance, are a type of metal-air battery that uses aluminum as the anode and air as the cathode. These batteries have a high energy density and are lightweight, making them suitable for certain applications like electric vehicles and backup power systems. Research is ongoing to improve the efficiency and lifespan of aluminum-based batteries, addressing issues such as aluminum corrosion and the development of efficient air cathodes.</p>

- Q: This question asks for a list of typical flaws or imperfections that can occur in aluminum products.

- <p>Common defects in aluminum products include porosity, which refers to small holes or voids within the material; surface defects such as scratches, dents, and discoloration; mechanical defects like warping or deformation; and metallurgical defects such as inclusions or impurities. Additionally, aluminum products can suffer from corrosion, which can lead to pitting or general surface degradation, and stress corrosion cracking, which occurs under certain environmental conditions and stress. Each of these defects can impact the structural integrity, appearance, or performance of aluminum products.</p>

- Q: Explain the interaction between aluminum and water, including any chemical reactions or properties.

- <p>Aluminum and water do not react directly under normal conditions. Aluminum is a reactive metal, but it is protected by a thin layer of aluminum oxide that forms on its surface when exposed to air, which prevents further reaction with water. This oxide layer is stable and acts as a barrier, making aluminum resistant to corrosion. However, in certain conditions, such as when aluminum is in contact with water and an electrolyte, it can lead to a process known as electrochemical corrosion. Additionally, aluminum can react with steam at high temperatures to form aluminum oxide and hydrogen gas.</p>

- Q: Describe the steps involved in recycling aluminum foil, including collection, sorting, processing, and manufacturing.

- <p>The process of recycling aluminum foil begins with collection, where used foil is gathered from households and businesses. It is then sorted to separate aluminum from other materials. The aluminum foil is shredded into small pieces and cleaned to remove any contaminants. This shredded material is melted in a furnace at high temperatures, turning it into molten aluminum. The molten aluminum is then cooled and rolled into sheets or ingots. Finally, these are used to manufacture new aluminum products, such as new foil, cans, or other items. This recycling process conserves resources, reduces energy consumption, and minimizes waste in landfills.</p>

- Q: Is it possible to utilize aluminum in the construction of building materials?

- <p>Yes, aluminum can be used to make building materials. It is known for its lightweight, high strength, and resistance to corrosion, making it ideal for various construction applications. Aluminum is commonly used in window frames, roofing materials, facades, and structural components. Its durability and recyclability also contribute to its popularity in sustainable building practices.</p>

Send your message to us

Aluminum Deep Drawing Quality Discs and Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords