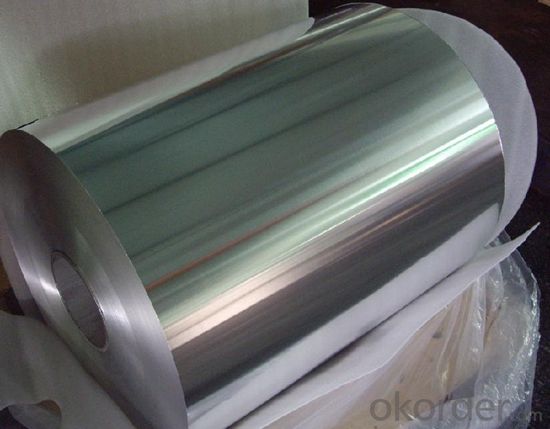

Aluminum Cold Rolled Coil for Gutter Making in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Gutter roof aluminium composite panel 1100 3003 pe pvdf price manufacture pre painted aluminum coil

Colored aluminum foil Brief Introduction:

| Aluminum Alloy: | AA1100,1050,1060,3003,3004,3005,3103,3105,5005,5052,5083,5754,6061,8011,O,O-H112,ETC. |

| Temper: | O,H16,H18,H22,H24,H26,H28 |

| Aluminum Alloy Thickness: | 0.08mm~1.2mm(0.08,0.18,0.28,0.38,0.48,0.6,0.8,1 mm) |

| (0.1,0.15,0.25,0.35,0.45 mm) | |

| Coil Width: | 30~1520mm hot sale price coated aluminium |

| Core Diameter: | 150/405/505mm |

| Coil Weight: | 1~2.5tons each coil for colorful marble coated aluminum coil |

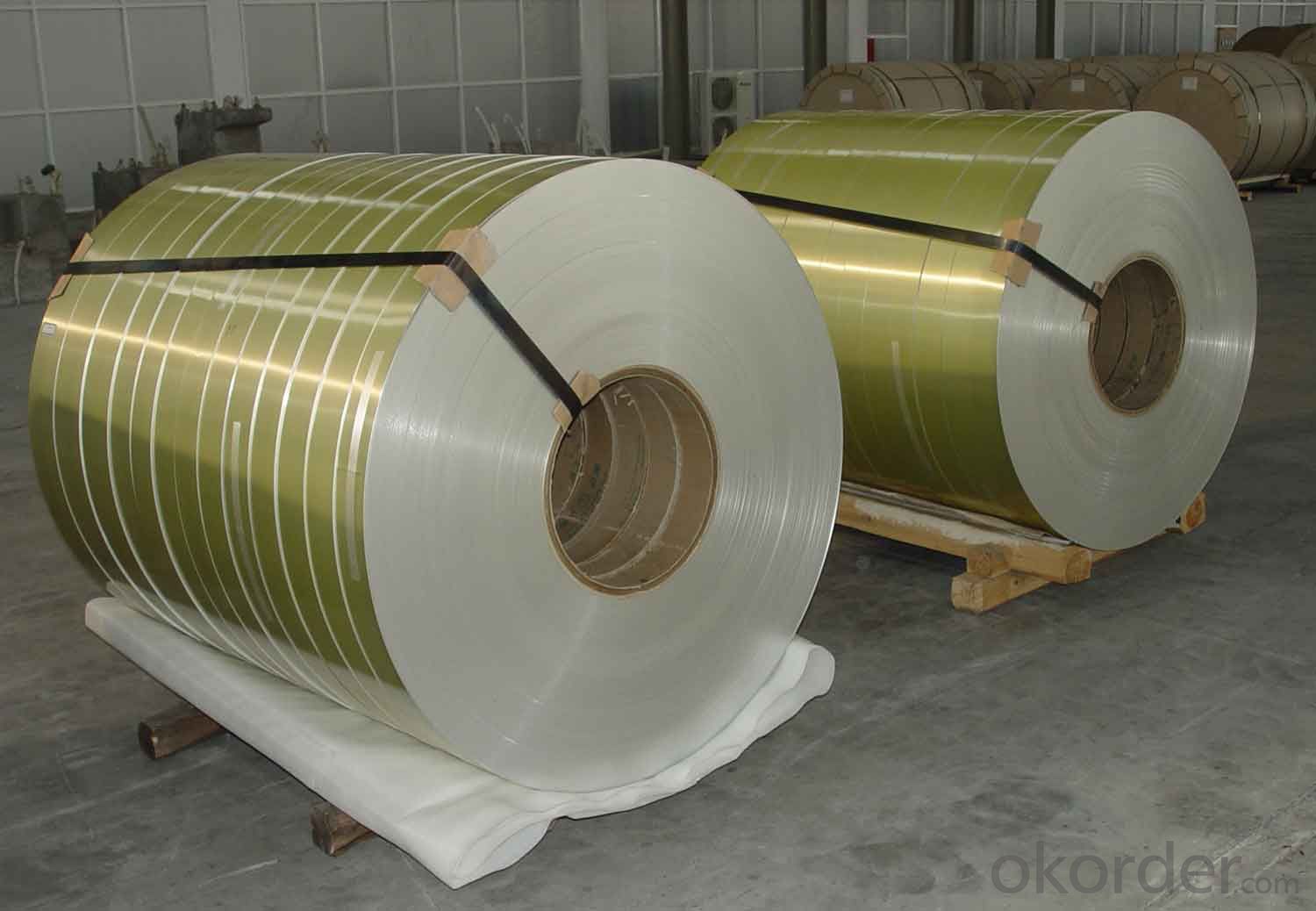

| Coating Type: | PE,PVDF,back coatting,ACRYLIC,feve |

| Surface Type: | Smooth,Embossed,mill finish,coated,brushed,etc.

|

| Glossness: | 10-90%(EN ISO-2813:1994) |

| Coating Thickness: | PE:more than 18 +-1micron |

| PVDF:more than 25+-1micron | |

| Back Coating:8~10+-1micron | |

| Coating Color: | Color A:pure white, ivory, white matte,yellow white,opal,light gray, aluminum natural color etc. |

| Color B:blue,yellow,gray,black,dark gray etc. | |

| Color C:white silver gray,flash silver,champagne etc. | |

| Color D:violet,pure orange,orange,bright red,china red,dark blue,brown,green,laker blue,flash gold yellow etc. | |

| Paint Hardness: | More than 2H |

| Coating Adhesion: | 5J(EN ISO-2409:1994) |

| Impact Resistance: | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Flexibility(T-bend): | <2T |

| MEK resistance: | More than 100 |

| Salt Fog Resistance(H): | ≥500 |

| Advantage: | 1.High temperature resistant colorful marble coated aluminum coil |

| 2.Weathering resistant | |

| 3.Scrubbing resistant | |

| 4.Sound insulation | |

| 5.Acid or alkali proof,Fireproof | |

| 6.Light weight material is easy to construct and install | |

| Packing Details: | Five-layer carton,strong polar fumigation wooden pallet,steel belt fastened outside,worthy shipping by sea. |

| Coating Aluminum Standard: | Chemical Composite:GB/T 3190-2008,JIS,EN,ASTM,Mechanical Property: GB/T 3880-2006, JIS, EN, ASTM |

| Certification: | ROHS,SGS,FDA,ISO9001:2008,GB/T 28001-2001,FORM A/E/F or CO,Mill Test Report |

| Application: | acp,aluminum composite panel,roof,gutter,ceiling,facade,wall cladding,gutter,aluminum honeycomb panel,roller shutter,rolling shutter,truck body,rolling shutter door,etc. |

Colored aluminum foil features:

1.Morn than 13 years experiences specializing in producing and servicing coated aluminum coil with pe,pvdf,back coating.

2.Famous brands Serving:reynobond,Alpolic,Alstone,Alstrong,alucoworld,indobond,etc.

3.More than 10 years joining cooperation and adopting famous-brand aluminum alloy from Southwest,Shandong Fuhai aluminum,etc,stabling aluminum alloy suppling in various kinds aluminium alloy with aluminum models of AA1100,3003,3005,1050,1060,1070,5052,etc.

4.More than 10 years joining cooperation and adopting famous-brand paints from Sweden Becker,and American PPG,which jointly issued 20years warranty for color coil coated,such as High temperature resistant,Excellent weather-proof durability,Anti-ultraviolet.

5.More than 12 years experiences in dealing with quality issues which guarantee for high quality and stable coated aluminum coil suppling.

- Q: Is it possible to recycle aluminum within the context of car battery recycling facilities?

- <p>Yes, aluminum can be recycled in a car battery recycling facility. Car batteries contain aluminum components, and recycling facilities are equipped to separate and recycle aluminum from other materials. The process typically involves disassembling the batteries, separating the aluminum casings from the lead acid, and then melting the aluminum for reuse. This not only conserves resources but also reduces the environmental impact of battery waste.</p>

- Q: Is it dangerous to consume food wrapped in aluminum foil due to the risk of aluminum poisoning?

- <p>There is minimal risk of aluminum poisoning from eating food wrapped in aluminum foil. Aluminum foil is designed to be food-safe and does not easily transfer aluminum to food under normal cooking conditions. However, at extremely high temperatures or when foil is used to cook acidic foods, there might be a slight increase in aluminum exposure. The body naturally excretes excess aluminum, and the small amounts typically ingested from food packaging are not considered harmful. Nonetheless, it's always a good idea to follow proper food handling and cooking practices to minimize any potential risks.</p>

- Q: The question seeks to understand the steps involved in producing aluminum, from raw material extraction to the final product.

- <p>The process of aluminum production involves several key steps. Initially, bauxite, the primary aluminum ore, is mined. This ore is then crushed and washed to remove impurities. The next phase is the Bayer Process, where bauxite is dissolved in a caustic soda solution under high temperature and pressure, resulting in a solution rich in aluminum hydroxide. This solution is then seeded with aluminum hydroxide crystals, causing more crystals to form, which are then harvested. The final step is the Hall-H茅roult Process, where the aluminum oxide is dissolved in a molten cryolite bath and electrolyzed to extract pure aluminum. This process involves passing an electric current through the bath, causing aluminum ions to be reduced at the cathode, forming molten aluminum which is then tapped off for further processing or use.</p>

- Q: Is there a link between aluminum exposure and the development of dementia?

- <p>Aluminum has been a subject of concern regarding its potential link to dementia, particularly Alzheimer's disease. However, current scientific consensus indicates that there is no conclusive evidence to support the claim that aluminum causes dementia. Extensive research has been conducted, and the majority of studies have not found a direct causal relationship between aluminum exposure and the development of Alzheimer's or other forms of dementia. While aluminum is naturally present in the environment and can be found in some foods, water, and medications, the body typically does not absorb significant amounts, and any absorbed aluminum is usually efficiently excreted. It is important to continue monitoring scientific research for any new findings, but as of now, aluminum is not considered a proven cause of dementia.</p>

- Q: Is it safe to use aluminum containers for food and drink in a microwave?

- <p>Aluminum is not recommended for use in microwave-safe containers for food and drink. While some aluminum containers are designed to be microwave-safe, they are typically coated with a non-metallic material to prevent arcing and damage to the microwave. However, most aluminum containers are not safe for microwave use as they can cause sparks and potentially damage the microwave. It's best to use microwave-safe plastics, glass, or ceramics specifically designed for microwave use.</p>

- Q: Is aluminum a component in the manufacturing processes of glass and ceramics?

- <p>Aluminum can be used in the production of glass and ceramics, although it is not a primary component. In glassmaking, aluminum is sometimes added to reduce the coefficient of expansion, making the glass more resistant to thermal shock. It can also improve the chemical durability and electrical insulation properties of the glass. In ceramics, aluminum compounds are used as opacifiers, colorants, or to enhance the mechanical properties of the final product. However, the use of aluminum in these industries is typically in small quantities and serves specific purposes rather than being a fundamental part of the material composition.</p>

- Q: What are the various applications of aluminum in the construction industry?

- <p>Aluminum is widely used in construction due to its lightweight, durability, and resistance to corrosion. It is utilized in the manufacturing of window frames, doors, roofing, and facades for its strength and low maintenance requirements. Aluminum is also used in structural components such as beams and columns, and in the construction of bridges and high-rise buildings. Its malleability allows for easy shaping and forming, making it ideal for intricate designs. Additionally, aluminum's thermal conductivity and reflectivity make it suitable for energy-efficient construction.</p>

- Q: Explain the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in building materials due to its lightweight, high strength, and corrosion resistance. It's utilized in window frames, doors, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum's malleability allows it to be shaped into various forms, making it ideal for facades and decorative elements. It's also used in structural components like beams and columns, and in electrical wiring due to its excellent conductivity. Additionally, aluminum's sustainability makes it a preferred choice in green building practices, as it's recyclable and has a low environmental impact.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum as a material in construction projects.

- <p>Aluminum in construction offers several advantages, including its lightweight nature, which reduces structural load and facilitates easier transportation and installation. It is also highly resistant to corrosion, making it ideal for outdoor applications and in areas with harsh weather conditions. Aluminum's recyclability contributes to sustainability, and it has a high strength-to-weight ratio, enhancing structural integrity. However, it has some disadvantages, such as being a poor conductor of heat, which may require additional insulation. It can also be more expensive than traditional materials like steel or concrete, and it dents easily, necessitating careful handling and maintenance.</p>

- Q: What precautions should be taken when handling molten aluminum to ensure safety?

- <p>Safety measures for working with molten aluminum include wearing appropriate personal protective equipment (PPE) such as heat-resistant gloves, face shields, and fire-resistant clothing. Ensure proper ventilation to avoid inhaling fumes. Use non-ferrous tools to avoid reactions with molten aluminum. Keep the work area clean and free from water, as it can cause violent reactions. Train workers on emergency procedures and have fire extinguishers suitable for metal fires readily available. Always work in teams to ensure someone can assist in case of an emergency.</p>

Send your message to us

Aluminum Cold Rolled Coil for Gutter Making in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords