Prepainted Aluminum Coils C.C Mill Finished 3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coils C.C Mill Finished 3xxx Description

Aluminum Coils C.C Mill Finished 3xxx has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Coils C.C Mill Finished 3xxx is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Coils C.C Mill Finished 3xxx

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

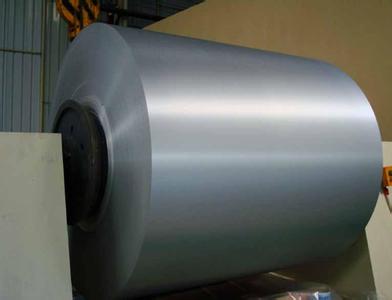

3.Aluminum Coils C.C Mill Finished 3xxx Images

4.Aluminum Coils C.C Mill Finished 3xxx Specification

| Alloy | AA3xxx (AA3003,AA3004,AA3005,AA3105 etc.) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm--100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Coils C.C Mill Finished 3xxx

A. Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

B.When will you deliver the products?

Aluminum Coils C.C Mill Finished 3xxx will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: How do aluminum coils contribute to energy-efficient windows and doors?

- Aluminum coils contribute to energy-efficient windows and doors by providing excellent thermal conductivity and allowing for better insulation. The coils are typically used to create frames for windows and doors, and their high thermal conductivity helps to transfer heat or cold more effectively. This allows for improved energy efficiency as the frames can effectively trap heat inside during winters and prevent heat from entering during summers, reducing the need for excessive heating or cooling. Additionally, aluminum coils are durable and low-maintenance, making them a sustainable and long-lasting choice for energy-efficient windows and doors.

- Q: Aluminum metal is oxidized in aqueous base with water serving as the oxidizing agent. Al(s) + H2O(1) → Al(OH)4- + H2(g) (basic solution) Write a balanced equation for this reaction in basic solution.

- Aluminium is an alloy not a metal.

- Q: Can aluminum coils be used for heat recovery systems?

- Indeed, heat recovery systems can utilize aluminum coils. Due to its exceptional heat conductivity, aluminum stands as an optimal option for heat transfer. In heat exchangers and heat recovery systems, aluminum coils frequently play a pivotal role in effectively transferring heat between different mediums. These coils are specifically engineered to maximize surface area, thereby enabling enhanced heat transfer. Furthermore, the lightweight and corrosion-resistant nature of aluminum renders it both durable and well-suited for a diverse range of applications within heat recovery systems.

- Q: Can aluminum coils be painted or printed on?

- Yes, aluminum coils can be painted or printed on. Aluminum coils are often coated with a protective layer that allows them to be painted or printed on. This opens up a wide range of possibilities for customization and branding purposes.

- Q: I can't figure out what the metabolic role of aluminum is. Been searching for a while and can't seem to find anything concrete.If you can, please include sources. Thanks!

- I okorder /

- Q: Which type of wheel is more durable, long-lasting and which wheel type would cost more, Aluminum or chrome?

- i like aluminum although it does wear easily.

- Q: How do aluminum coils contribute to thermal insulation?

- Thermal insulation is enhanced by aluminum coils in multiple ways. Firstly, aluminum possesses a remarkable reflective property, enabling it to deflect heat and radiation away from the surface. This characteristic effectively reduces the amount of heat absorbed by the coil and transmitted to the surroundings. Additionally, aluminum coils are frequently employed in conjunction with insulation materials like foam or fiberglass. These insulating materials create air pockets that serve as a barrier against heat transfer. The aluminum coil acts as a safeguard, shielding the insulation material from any potential harm or compromise. Moreover, aluminum is a lightweight material that exhibits exceptional resistance to corrosion. This feature allows for the versatile use of aluminum coils in various applications, including HVAC systems, where they contribute to maintaining a consistent temperature by minimizing heat loss or gain. In summary, aluminum coils assume a critical role in thermal insulation by deflecting heat, safeguarding insulation materials, and imparting durability and longevity to the insulation system.

- Q: Supposably water ozidies it what ever that means so how in the world do i clean an aluminum bike if i cant use water? i like to use water and soap on my carbon bike so what do i use on a aluminum?

- You can use water and soap. Aluminum does not rust and will not be harmed by water. Happy washing

- Q: What are the various techniques used in the manufacturing process to create insulation for aluminum coils?

- <p>Aluminum coil insulation is produced using several methods, including lamination, extrusion, and coating. Lamination involves stacking thin sheets of aluminum with insulating material between them. Extrusion is a process where aluminum and insulation materials are pushed through a die to create a continuous profile. Coating methods apply a layer of insulating material directly onto the aluminum coil surface. These methods ensure the insulation maintains its properties under varying conditions, providing electrical isolation and protection against environmental factors.</p>

- Q: Can aluminum coils be used for solar panel applications?

- Yes, aluminum coils can be used for solar panel applications. Aluminum is a lightweight and durable material that is commonly used in the construction of solar panels. It is an excellent conductor of electricity, making it ideal for capturing and conducting solar energy. Aluminum coils can be used as a backing material for solar panels, providing structural support and helping to dissipate heat. Additionally, aluminum has good corrosion resistance, which is important for solar panels that are exposed to various weather conditions. Overall, aluminum coils are a popular choice for solar panel applications due to their strength, conductivity, and resistance to corrosion.

Send your message to us

Prepainted Aluminum Coils C.C Mill Finished 3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords